Harrington Hoists and Cranes Food Grade Supplement (ER2/MR2/PT) User Manual

Page 8

8

6.2 Lubrication – Load Chain, Hooks, and Suspension

6.2.1

Load Chain

• For longer life, the load chain should be lubricated.

• The load chain lubrication should be accomplished after cleaning the load chain with an acid

free cleaning solution.

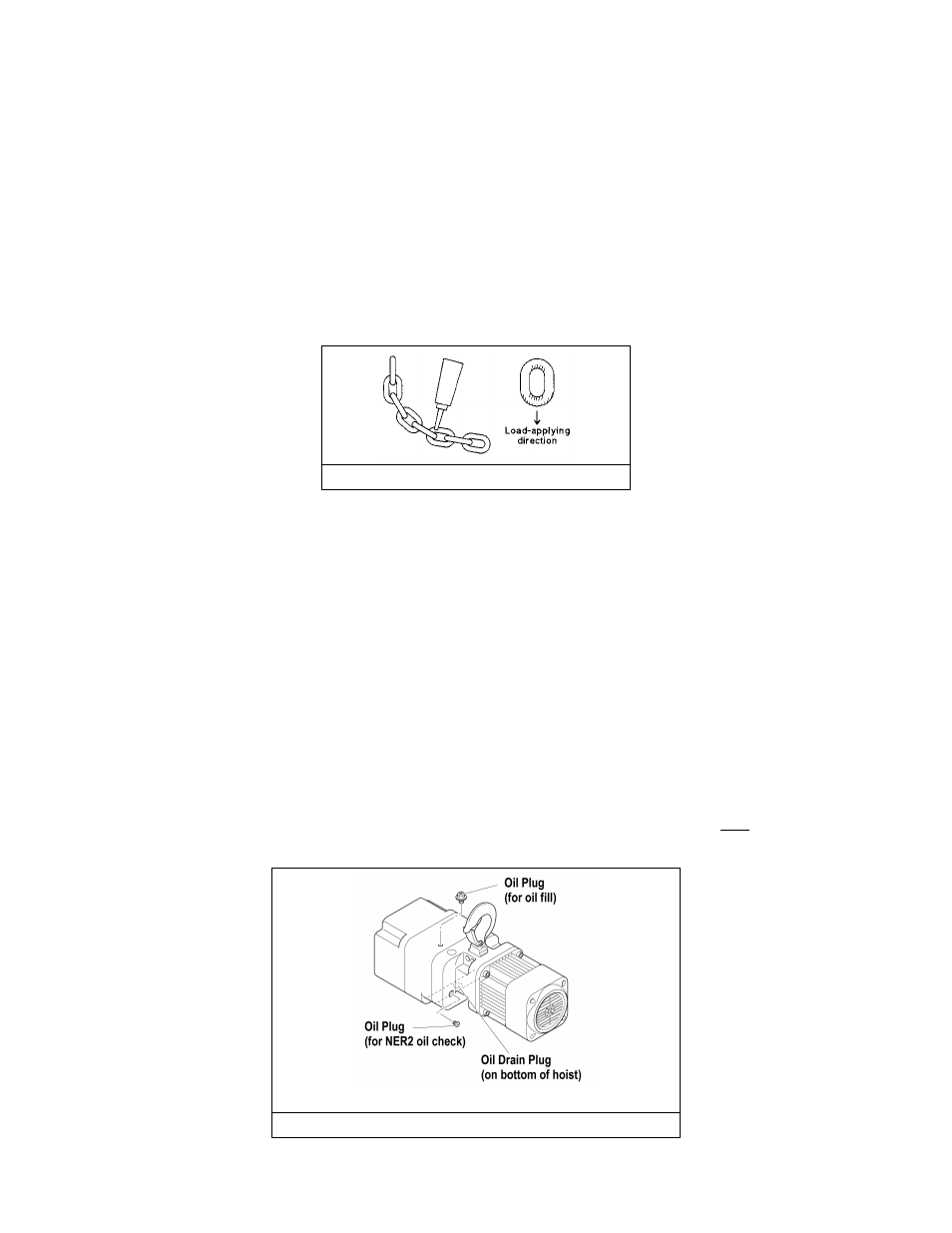

• Apply only Harrington Hoist, Inc. food grade lubricant (Part No. 2AFG003S1951) to the bearing

surfaces of the load chain links as indicated by the shaded areas in Figure 6-2. Also apply the

lubricant to the areas of the load chain (shaded areas in Figure 6-2) that contact the load

sheave. Ensure that the lubricant is applied to the contact areas in the load sheave pockets.

Figure 6-2 Chain Grease Application

• The load chain should be lubricated every 3 months (more frequently for heavier usage or

severe conditions).

6.2.2

Hooks and Suspension Components

• Hooks – Bearings should be cleaned and lubricated at least once per year for normal usage.

Use only Nevastane HT/AW 2 White Drum food grade lubricating grease. Clean and lubricate

more frequently for heavier usage or severe conditions.

• Suspension Pins – Lubricate at least twice per year for normal usage; more frequently for

heavier usage or severe conditions.

6.3

Lubrication - Gearbox

6.3.2

DETERMINING OIL LIFE - Refer to Section 6.1.3 in the ER2OM when estimating gear oil life

based on operations.

6.3.3

NER2 OIL LEVEL – The oil level is checked by removing the oil plug on the side of the hoist as

shown in Figure 6-3 for NER2 hoists. The oil level should be just below the hole when the hoist is

level.

NER2 Hoists

Figure 6-3 Oil Plug Locations