0 inspection – Harrington Hoists and Cranes ED 1050 Supplement - (ED3) User Manual

Page 10

10

5.0 Inspection

The information listed in this section is intended to supplement Section 5.7 of the EDOM.

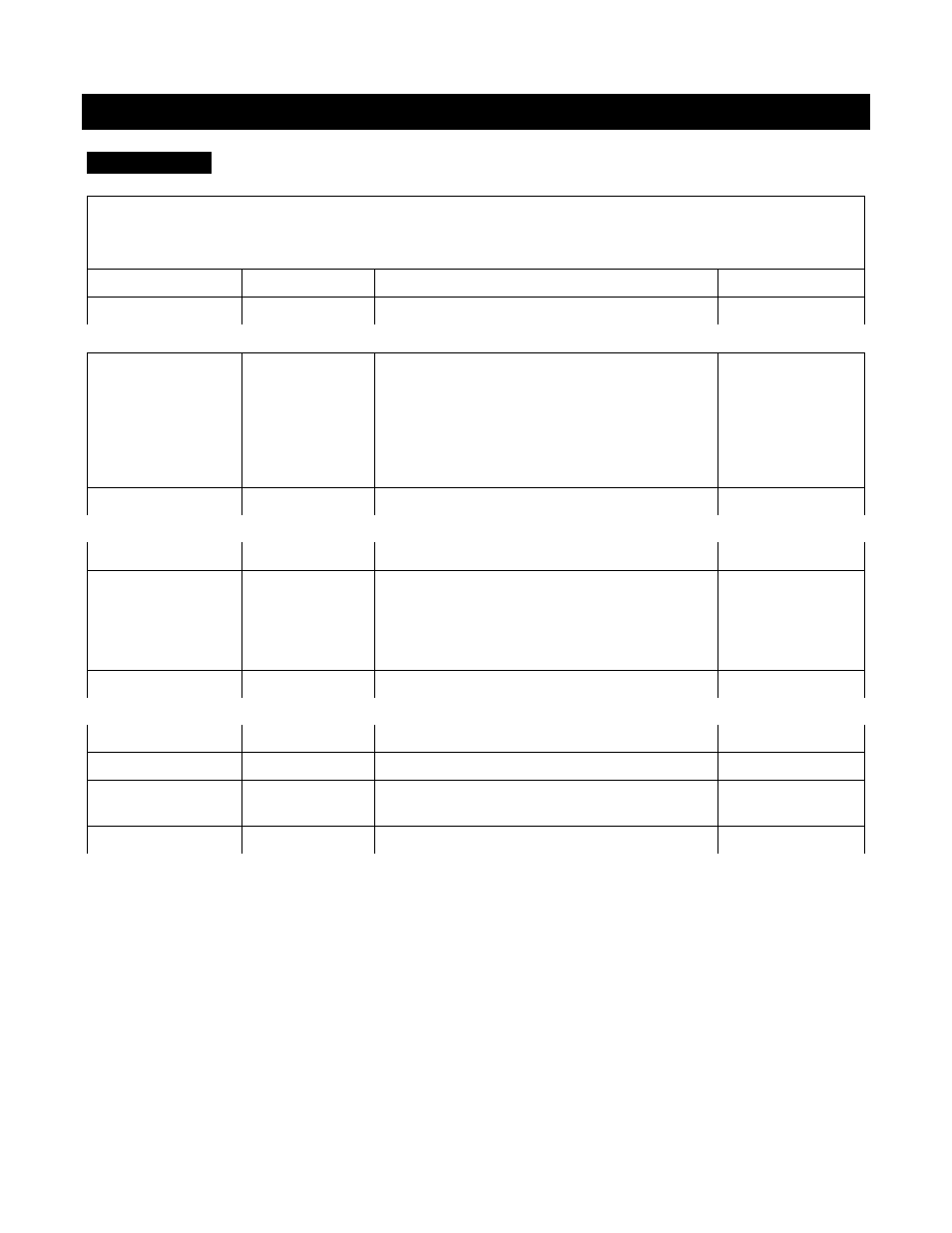

Table 5-3

Hoist Inspection Methods and Criteria

Use this table in conjunction with Table 5-3 of the EDOM. The entries in this table replace in their

entirety the corresponding entries in Table 5-3 of the EROM.

Item

Method

Criteria

Action

Hooks - Idle

Sheave and Axle

(Bottom Hook on

Double Fall Hoist)

Visual, Function

Pockets of Idle Sheave should be free of

significant wear. Idle Sheave surfaces should

be free of nicks, gouges, dirt and grime.

Bearing parts and surfaces of Idle Sheave and

Axle should not show significant wear. Idle

Sheave should rotate freely with no roughness

or significant free play.

Clean/lubricate, or

replace as

required.

Load Chain -

Reeving

Visual

Chain should be reeved properly through Load

Sheave (and Idle Sheave for double fall hoist) -

refer to

Section 6.4

. Chain, Chain Spring,

Cushion Rubbers, and Stoppers should be

installed properly - refer to

Section 3.2

.

Reeve/Install

chain properly.

Cushion Rubber

Visual

Should be free of significant deformation.

Replace.

Chain Springs

Visual

Chain springs should not be deformed or

compressed.

Replace.