Danger, Warning, Battery selection & installation – Gillette Generators SPP-180 User Manual

Page 16

PAGE 16

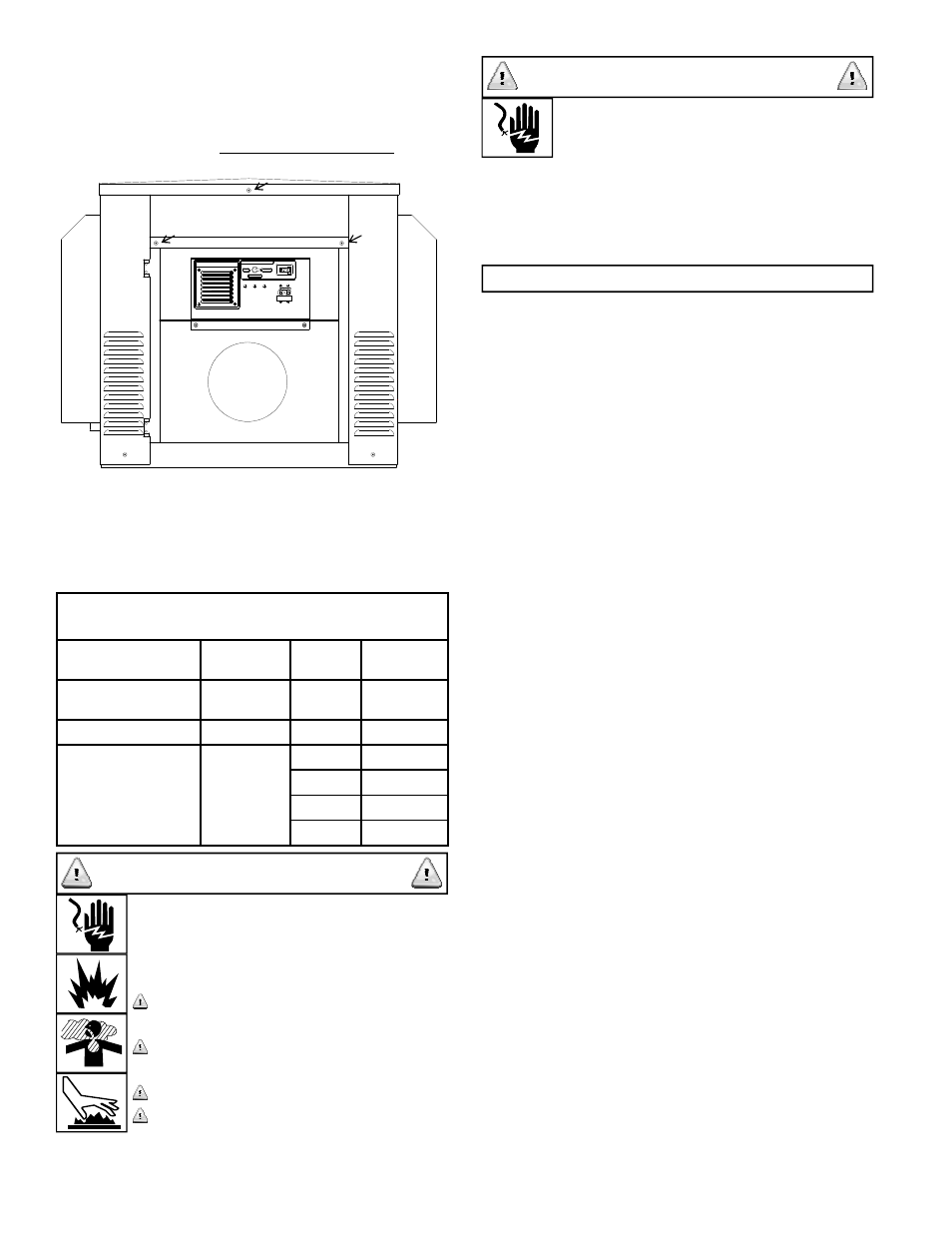

Electrician must remove (3) cap screws (see arrows)

and slide panel down 2 inches, then pull straight out

for complete removal. At this point, high voltage

wiring terminals are exposed. Replace panel by

positioning it 2” under roof, sliding it upwards until it

stops, then replacing (3) cap screws.

The high voltage access panels should only

be removed by experienced licensed

electricians, repair and service personnel,

and installers.

Electrical

shock

from

mishandled

battery.

Toxic fumes from battery or engine

exhaust may be inhaled.

Hot surfaces may cause severe burns.

Explosions from battery or dry fuel

fumes being ignited by careless smoking or

sparks from mishandled tools.

At engine end, behind bolted panel

contains

dangerous

high

voltage

electricity. These voltages can cause a

fatal electric shock and will cause sudden illness,

dizziness, and incoherent actions. Only experienced

licensed

electricians

and

authorized

service

technicians should have access to this high voltage

area.

The 12 VDC battery is not furnished with the standby

generator set. The generator can be installed in a

wide range of temperatures and climate conditions.

As climates get colder, batteries loose their ability to

produce required power. Therefore, battery size

must be increased.

Climates that reach to a low of 30º F (-1.1 º C) can

achieve good generator operation with a 12 VDC, 45

amp hour battery. Climates that reach below this

temperature line should have a 55 amp/hour 12 VDC

battery.

CAUTION: All 12 VDC batteries will loose a certain

percent of their charge while in storage. It is very

important to test the battery voltage before it is

installed in generator and taken to jobsite. A fully

charged battery must test at 12.5 – 13.0 volts DC.

Also, the correct battery for models SPS-120 and SPP-

180 must have lug terminals to match lug battery

cables, for a bolt-together connection.

This generator is equipped with a battery tray, a

battery hold down strap and battery cables. Place the

selected fully charged battery with full electrolyte in

battery tray and secure with battery hold down

clamp.

Before connecting battery cables to battery, complete

the following steps:

1) Set the generator’s toggle switch to “OFF” position.

Remove the 20 amp fuse near the remote start/stop

terminal block (labeled “S” & “+”) on the back panel

of the control circuit (see these locations at “Know

Your Systems Control Panel” on page 11).

2) Turn off utility power supply to the previously

installed automatic transfer switch.

3) Battery cables are factory connected at the

generator points. Electrician should connect the red

battery cable (from engine starter solenoid point) to

battery post shown with “positive”, POS, or (+)

indicator. Connect the black battery cables (from

frame ground) to the battery.

DANGER

BATTERY SELECTION & INSTALLATION

WARNING

FOR LICENSED ELECTRICIAN’S USE, ONLY

When hinged door on generator end of housing is un

-locked and opened, the control panel is exposed.

(see item 1, 8 point diagnostic display panel on page

11). An access panel, for electrician’s use only, is

located at top of hinged door access.

TIGHTENING TORQUE REQUIREMENTS FOR

FIELD WIRING TERMINALS

FIELD CONNECTION

SCREW SIZE

WIRE SIZE

AWG

TORQUE

(LB/IN)

TS1

REMOTE START WIRES

#6

14

12

COMMERCIAL POWER

#6

14

12

TS2 GENERATOR

OUTPUT & EXTERNAL

GROUND LUG

18-10

20

8

25

6-3

35

2

40

LUG TYPE

CONNECTOR

HIGH TEMPERATURE

ENGINE MONITOR

OVER CRANK

OVER SPEED

ENGINE RUNNING

UNDER SPEED / FAIL

LOW OIL

NOT IN STANDBY

LOW BATTERY

MODE SELECTOR

TEST

OFF / RESET

STANDBY

SenDEC

ON

ON

50 AMP

CIRCUIT BREAKER

HINGED DOOR REMOVED

FOR CLARITY

(PANEL COVERING HIGH

VOLTAGE TERMINALS)