Lpg gas fuel, Critical points for a proper lpg gas installation – Gillette Generators SPP-180 User Manual

Page 14

PAGE 14

LPG GAS FUEL

This home generator system has been set up at the

factory for natural gas fuel, unless it has been

specifically ordered for vapor withdrawal liquid

propane gas (LPG). This installation/operation guide

will explain the factory LPG system. Additional

information is available upon request for field

conversion from one fuel to the other.

LPG fuel is typically at farms or remote areas where

there is no natural gas fuel.

LPG must be a vapor withdrawal system (the

generator will not work on liquid withdrawal

systems). Proper LPG is clean and free of moisture

or particulate matter. It consists of a propane HD5

grade with minimum 2500 BTU’s per cubic foot

energy rating. A typical blend is 5% propylene and

butane plus a minimum 90% propane.

Required LPG vapor withdrawal fuel pressure is

11-14 inches water column at (6-6½ ounces) 2500

BTU’s per cubic feet.

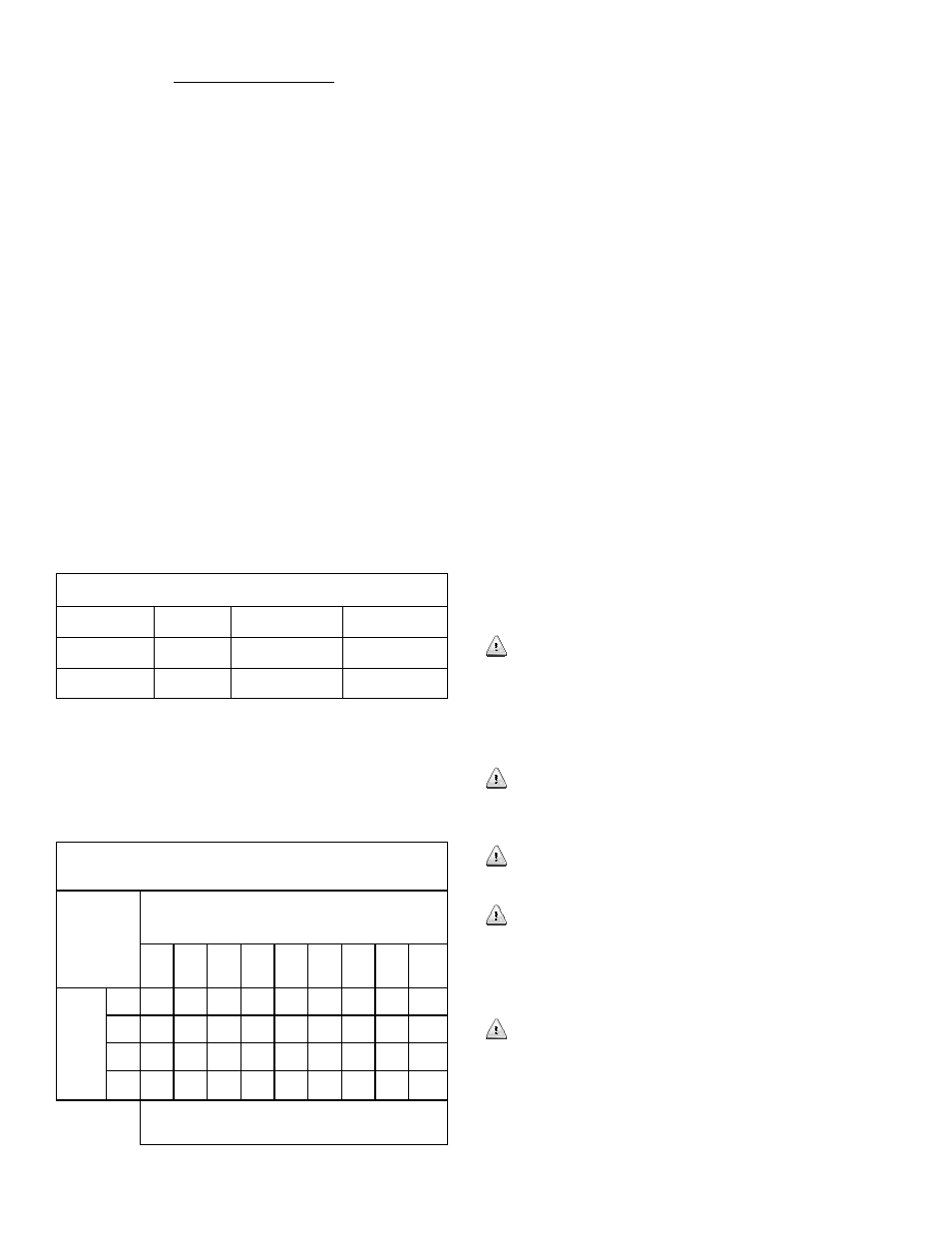

Figure 4

*BTU VALUES BASED ON 2500 BTU’S PER CUBIC FEET GAS

SUPPLIER MAY NEED TO KNOW LPG CONSUMPTION AT FULL

LOAD, IN MEASUREMENTS OF CUBIC FT./HOUR OR BTU/HOUR.

Figure 5

CAUTION: It is critically important to understand,

that as a specific fuel line pipe diameter is extended

in length, its ability to carry the volume of gas,

diminishes in direct proportion.

EXAMPLE 1: In reading the charts: A model SPS-120,

12 KW generator is to be installed 50 feet from LPG

fuel tank. Figure 4 chart shows this model to require

87 cubic feet per hour, gas volume to be delivered to

generator. Figure 5 chart shows the required 87

cubic feet can be delivered over a 50 foot distance

with ¾” diameter fuel pipe.

EXAMPLE 2: A model SPP-180, 18 KW generator set

is to be installed 70 feet from LPG tank. In reading

the charts, fig. 4 chart show this model to require 135

cu.ft./hr. gas volume to be delivered to generator.

Fig. 5 chart shows the required 135 cu.ft. can be

delivered over a 50 ft. distance with a 1” diameter

fuel pipe.

INSTALLER’S RESPONSIBILITY: Use Figure 4

chart to learn cubic feet/hour value of generator to

be installed. Use Figure 5 chart to learn minimum

pipe size diameter and maximum distance from

LPG tank to insure sufficient fuel volume from

LPG tank to generator.

CRITICAL POINTS FOR A PROPER LPG

GAS INSTALLATION

Before LPG fuel line plans are made, call your

LPG supplier, give information on the amount of cubic

feet/hour (Figure 4) and BTU’s/hour (Figure 5) that

your generator will use, and ask about local codes

and regulations concerning LPG fuel connected to

generators.

Only LPG vapor withdrawal (not LPG liquid

withdrawal) will work on these generators. Make

sure the LPG tank has the correct fuel.

LPG fuel pressure must be 6 ounce pressure (11

-14 inches water column) delivered to the generator.

Often new LPG tanks or existing LPG tanks

already located at the installation site, have a pre-

installed, primary regulator set for 250 PSI and

intended for home heating and cooking. This is

wrong for generator fuel.

The LPG fuel tank must have a dedicated primary

LPG fuel regulator mounted at the tank fuel outlet

point, and set for 6 ounce pressure (11-14 inches

water column). A direct, dedicated fuel line

connected to the 6 ounce fuel tank primary regulator,

must be connected directly to the generator mounted,

secondary regulator, also, set at 6 ounce pressure.

LPG FUEL CONSUMPTION AT FULL LOAD

Gen. Model

Gen. KW

Cubic Ft./Hr

BTU/Hr. *

SPS-120

12.0

87

220,000

SPP-180

18.0

135

337,500

LPG FUEL LINE MAXIMUM DIAMETERS & LENGTHS

Pipe Length

In Feet

Allowed Distance From LPG Tank

to Gen-Set

0-

10

11-

20

21-

30

31-

40

41-

50

51-

60

61-

70

71-

80

81-

90

P

ip

e

D

ia

m

e

te

r

In

In

ch

e

s

½

110

76

61

---

---

---

---

---

---

¾

227 157 126 107

95

87

78

70

62

1

428 293 236 201 179 164 151 138

129

1¼

807 523 445 379 338 309 285 255

242

Cubic feet of LPG (vapor withdrawal) that can

safely be carried in it’s matching pipe diameter.