Gillette Generators SPP-180 User Manual

Page 13

PAGE 13

EXAMPLE 2: A model SPP-180, 16 KW generator is to

be installed 50 feet from gas meter. In reading the

charts, Fig. 1 shows this model to require 280 cubic

feet/hour (or 280,000 BTU/hr) gas volume to be

delivered to generator. Figure 2 chart show this

required 280 cu.ft. can not be delivered with a ¾” or

1” pipe. Only a 1¼” diameter pipe can safely deliver

the 280 cu.ft. gas requirement, over a 50 foot

distance.

INSTALLER’S RESPONSIBILITY: Use Figure 1

chart to learn cubic feet/hour value of generator to

be installed. Use Figure 2 chart to learn minimum

pipe size diameter and maximum distance from

gas meter, to insure sufficient fuel volume from

natural gas meter to generator set.

CRITICAL POINTS FOR A PROPER

NATURAL GAS INSTALLATION

Before natural gas fuel line plans are made, call

your natural gas supplier, give information on the

amount of cubic feet/hour and the BTU’s/hour that

generator will use, and ask if natural gas meter and

primary regulator, is adequate for your natural gas

generator. Natural gas companies have different

meters for increasing BTU gas demands.

Check the natural gas primary regulator,

connected at natural gas meter output. The correct

primary regulator is set at 6 to 8 inches water column

(4 to 4½ ounces pressure or 0.19 to 0.26 PSI). The

existing primary regulator (for other gas appliances)

may be too small to run your gas driven generator.

A dedicated natural gas fuel line and primary

gas regulator (if required) is mandatory for proper

operation.

A flexible natural gas fuel line is furnished for

installation between utility gas line and generator for

input.

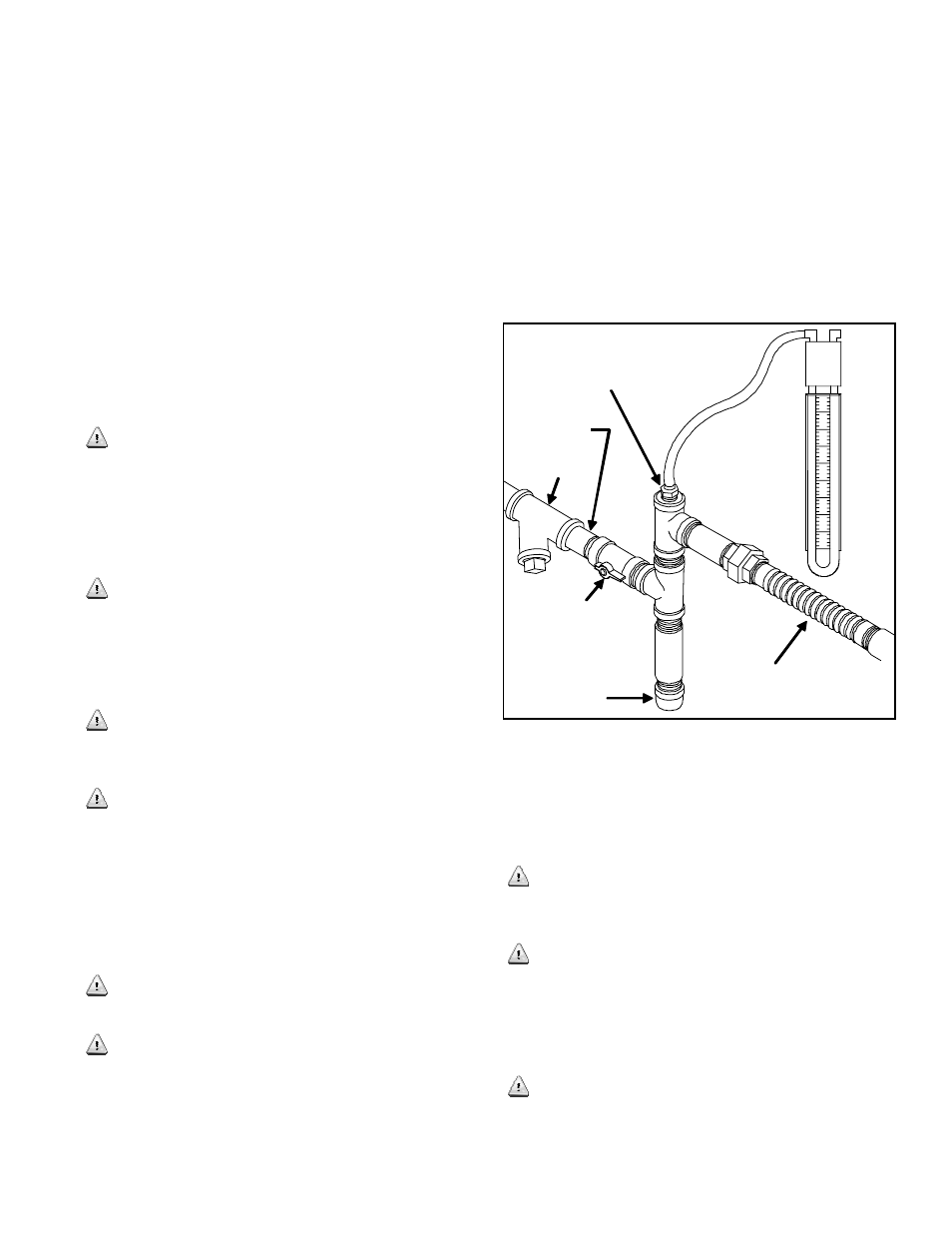

CAUTION: Make sure this flexible fuel line is

installed in horizontal position without bends. A

bend of any kind in this flexible line could lead to

an eventual crack in the bend, causing a possible

leak. See Figure 3 for a recommended installation.

Make sure fuel pipe installation and connection at

generator includes an on/off manual gas valve.

All new installations, plus any future repair or

troubleshooting procedures must include a natural

gas manometer test. This test should be conducted

after all other natural gas appliances have been

turned on. After all appliances are running, start the

generator. If manometer stays within 6 to 7 inches

water column with full load applied to a proper

running generator, it’s a good installation. (See

Figure 3)

If manometer reading falls below 5 inches water

column while generator engine is cranking, or

running, it may indicate the gas meter or primary

regulator is too small, or the fuel pressure from gas

supplier is inadequate. Any of these three problems

will cause a fault in proper generator operation.

If manometer reading stays within the 6 to 7 inches

water column, but generator engine still will not start,

or it runs erratic, it may indicate insufficient fuel

volume due to long fuel line runs or fuel pipe

diameter is too small. Check calculations of chart in

Figure 1 & 2.

Figure 3

NOTE: After completion of all gas tests, remove

manometer and replace blank plug, using fresh pipe

sealant.

For additional precautions, a manual fuel shut-off

valve should also be installed inside the building, for

those locations with inside gas meters.

Climates that have snow and ice build-up, along

with sub-zero temperatures, should have gas fuel

piping protection against freezing. The generator

end of the hard piping installation should include a

sediment trap to drain any condensation, and a line

filter. (See Figure 3)

Best installations happen when electric utility

meter and gas meter are close together, as it results

in short runs for both electric wires and fuel lines.

When these two utilities are far apart, always choose

to locate gen-set close to the gas meter, as installation

Sediment Trap

Dedicated

Natural Gas

Fuel Line

Manometer

Reading

Must Be 6”

to 7” Water

Column

Gas Fuel To

Generator

On/Off Valve

Furnished

Flexible

Gas Pipe

(without

bends or

angles)

Manometer Port: Remove

Blank Plug And Insert

Manometer Plug

Line Filter