Generator performance, Prepare the generator for operation – Gillette Generators SPP-180 User Manual

Page 15

PAGE 15

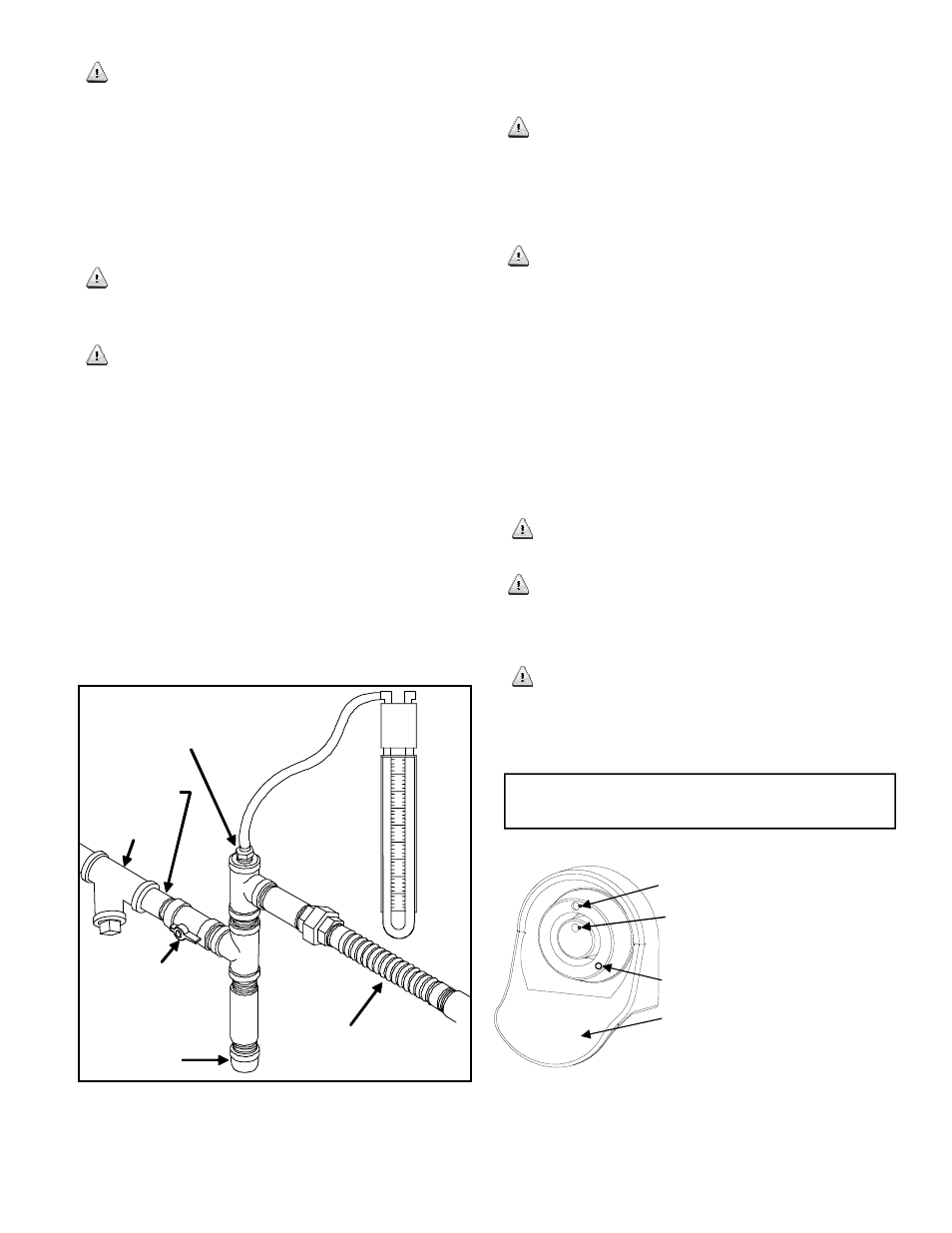

A flexible LPG fuel line is furnished for

installation between the LPG fuel line & generator fuel

input.

CAUTION: Make sure this flexible fuel line is

installed in a horizontal position, without bends.

A bend of any kind, in this flexible line could lead

to an eventual crack in the bend, causing a

possible fuel leak. See Figure 6 for recommended

installation.

Make sure fuel line installation includes an on/off

manual gas valve at both the LPG tank and at

connection point of generator.

All new installations, plus any future repair or

troubleshooting procedures must include an LPG

manometer test. This test should be conducted after

all other LPG appliances are turned on. After all

appliances are working, start the generator. If

manometer stays within 10 to 12 inches water column

with full load applied to generator, it’s a good

installation. (See Figure 6) If manometer reading

falls below 10 inches water column while generator is

cranking or running, it may indicate the primary

regulator on LPG tank is wrong or the LPG tank is too

low to produce the vapors required to operate

generator.

If manometer reading stays within 10 to 12 inches

water column, but generator will not run properly, it

may indicate fuel line length is too long or fuel line

diameter is too small to deliver proper volume of fuel.

Check calculations from charts in Figure 4 and 5.

Figure 6

NOTE: After completion of all gas tests, remove

manometer and replace blank plug, using fresh pipe

sealant.

Climates that have snow and ice build-up, along

with sub-zero temperatures should have LPG fuel

pipe protection against freezing. The generator end

of the hard piping installation should include a

sediment trap to drain any condensation and a line

filter. (See Figure 6)

Best installations happen when electric utility

meter and LPG tank are reasonably close (20 Ft. to 50

Ft.), as it results in short runs for both electric wires

and LPG fuel lines. When these two identities are far

apart, always choose to locate generator as close to

the LPG tank as possible, because installation costs

are lower when increased wire size must be used for

longer runs rather than increased fuel pipe dia.

GENERATOR PERFORMANCE

When matching a generator to a specific application,

whether gross intermitted or gross continuous power

is used, it is important to derate this power output for

the following adverse conditions:

Engine power rating after “break-in” is usually

within 3% of engine published rating.

Temperature

and

altitude

directly

derate

generator power. Derate 3½% for each 1,000 feet

above 326 feet, over sea level. Derate 1% for every

10º F (5.6º C) over 77º F (25º C).

Generator location is important. If it is located

too far from fuel source, fuel line may not deliver

adequate fuel. If it is located too far from electric

distribution box, the electric power lines may not

deliver adequate electric power. Both examples will

directly

affect

generator power.

Read

section

“The

Gaseous

Fuel

System

Installation”

on

page 12 & 14 for

full details.

All

generator

access doors are

locked,

and

are

opened with a common key for

all locks. Notice the door lock (in the locked position)

has matching dot system in alignment. Insert the key

into lock and turn counterclockwise. Remove the key

and note, the dots are now out of alignment. Re-insert

PREPARE THE GENERATOR

FOR OPERATION

Stationary Dot

Dot-aligned,

Locked

Position

Un-Locked

Position

Raised

Finger

Hold

ACCESS TO HOUSING INTERIOR

Sediment Trap

Dedicated LPG

Fuel Line from

LPG Tank

Manometer

Reading

Must Be 6”

to 7” Water

Column

Gas Fuel To

Generator

On/Off Valve

Furnished

Flexible

Gas Pipe

(without

bends or

angles)

Manometer Port: Remove

Blank Plug And Insert

Manometer Plug

Line Filter