Hrv and erv typical installations (cont’d) – Reversomatic Economy Series User Manual

Page 11

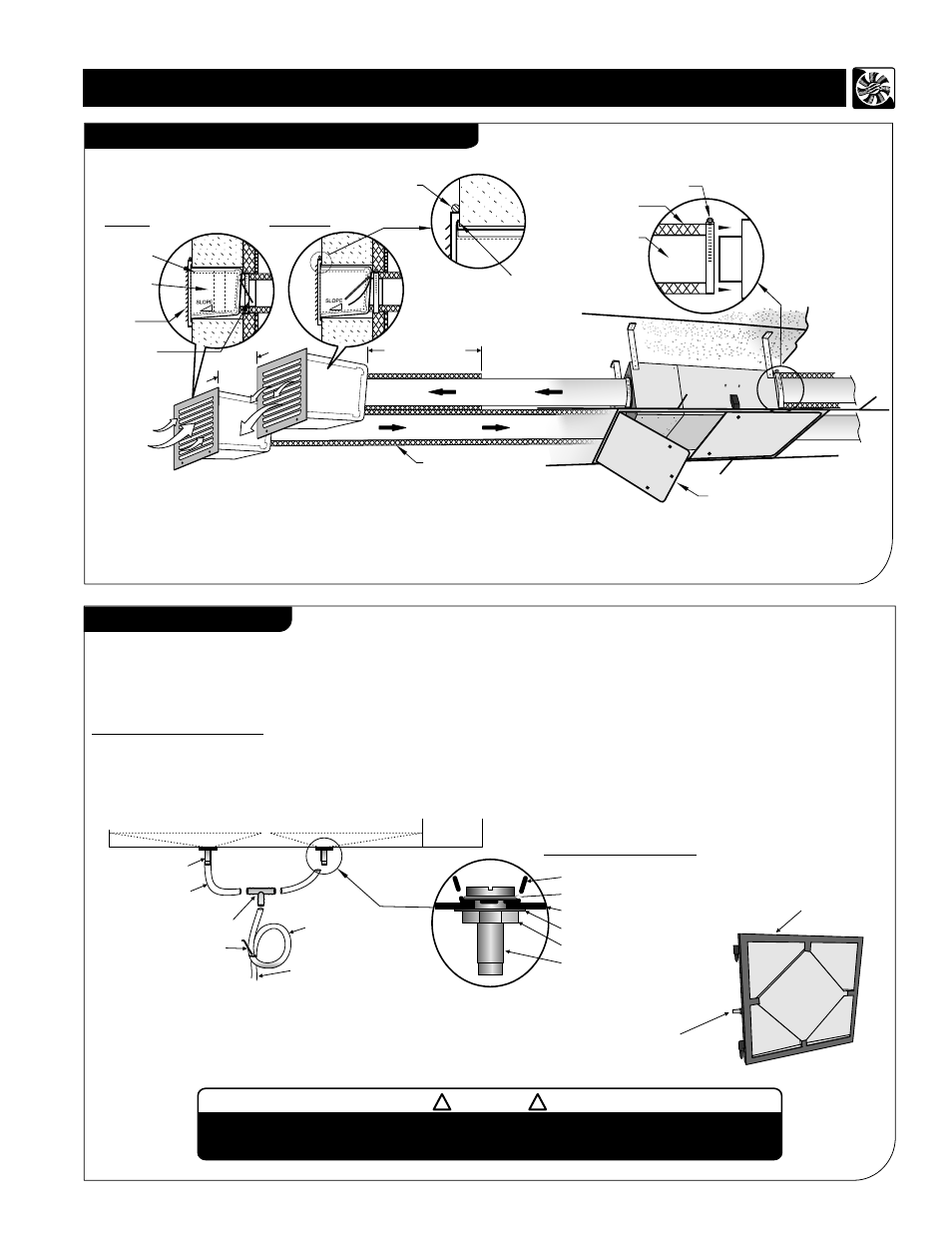

Drain Connection

During defrost cycle the HRV unit may produce some condensation and the water should flow into a nearby drain.

The HRV cabinet has pre-punched holes for the drain, in order to keep the drain pan intact

hand tighten the 2 plastic drain

tube to the unit using the gasket and nuts.

Cut two sections of ½" drain pipe and connect the other ends to the drain tube then connect to “ T ” connector. Connect a

drain line and create a

P-trap to prevent the unit from unpleasant odours from drain source. Tape or fasten base to avoid

any bends.

The HRV and all condensate lines must be installed in a space where the temperature

is maintained above the freezing point or freeze protection must be provided.

CAUTION

!

!

Minimum 5 Feet

(1” Thick)

Intake

Exhaust

Insulation

CAULKING GRILLE

- 3 SIDES ONLY, NOT ON BOTTOM

CAULKING WALLBOX

- CAULK WALLBOX TO

STRUCTURE ON ALL 4 SIDES

Minimum

5 Feet

Metal Clamp

Insulation

Duct

Backdraft

Damper

Grille

Insulation

Wallbox

Access Door

9

Note:

For Horizontal installation,

connect only 1 drain spout assembly on lid / door.

cut one ½’’ drain pipe and connect one end to the drain spout and the other

end to the drain line. Don't forget to create a P-trap as shown above.

For Vertical installation

“ T ” Connector

½” I.D.

Drain Pipe

Zip Tie

Drain Spout

to Drain

Drain Pan

“P” Trap

Drain Pan

Drain Spout Assembly

Rubber washer

Drain Spout

Nut

Steel washer

HRV/ERV Steel Housing

Plastic Drain Pan

Lid

HRV and ERV Typical Installations (cont’d)

Typical Installations of Single Vents & Access door

(For vertical installation)

Use this drain for

horizontal installation

Fresh air intake and supply duct must be totally insulated. Exhaust duct

must be 5 feet insulated. In colder climate, it is recommended to insulate

all exhaust and supply ducts.

Note:

Note:

Use appropriate access door size for easy access and

routine maintenance of the unit. For more info visit

http://www.reversomatic.com/HRV&ERV/Accessories