Archive, Airtronic - operation, External discrete signals – Ransburg AirTronic 79053 User Manual

Page 10

LN-9241-02.1

AirTronic - Operation

7

7

7

7

7

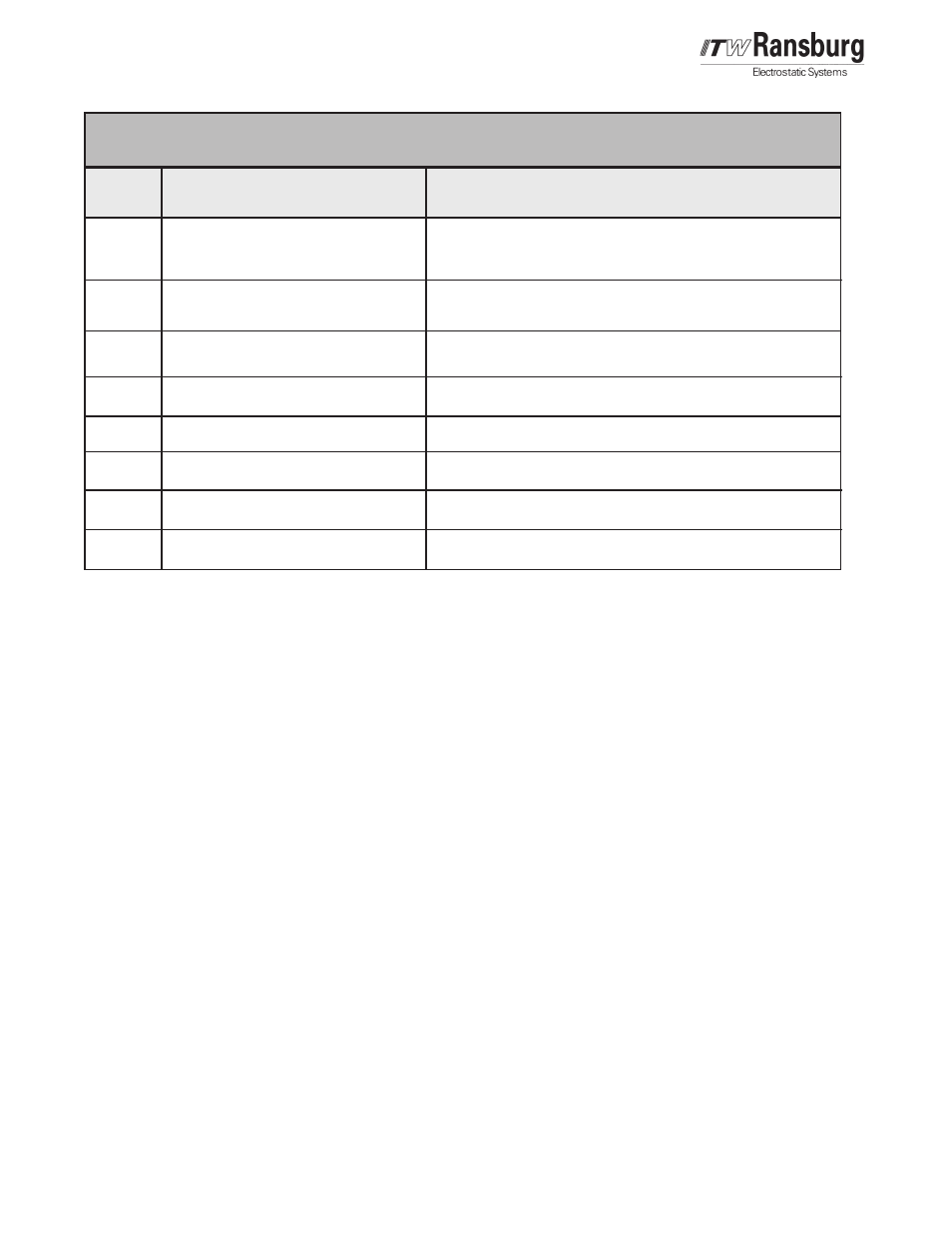

P I N

P I N

P I N

P I N

P I N

#

#

#

#

#

S I G N A L

S I G N A L

S I G N A L

S I G N A L

S I G N A L

DESCRIPTION

DESCRIPTION

DESCRIPTION

DESCRIPTION

DESCRIPTION

1

2

3

4

5

6

7

8

Channel 1 Analog Set Point *

Channel 2 Analog Set Point *

Channel 1 Trigger

Channel 2 Trigger

Channel 1 Hold

Channel 2 Hold

Serial Bus (+)

Serial Bus (-)

0-10V = 0 To Full Scale

4-20 mA = 0 To Full Scale

0-10V = 0 To Full Scale

4-20 mA = 0 To Full Scale

24 Vdc if Status Condition Is Active **

24 Vdc if Status Condition Is Active **

24 Vdc If Status Condition Is Active **

24 Vdc If Status Condition Is Active **

Serial Bus to Remote Unit

Serial Bus to Remote Unit

EXTERNAL DISCRETE SIGNALS

EXTERNAL DISCRETE SIGNALS

EXTERNAL DISCRETE SIGNALS

EXTERNAL DISCRETE SIGNALS

EXTERNAL DISCRETE SIGNALS

* Set by Display Module SW2, Position 7. (Off = 0-10 Vdc & On = 4 to 20 mA)

** Set by display Module jumper E2

E2 Pins 1 & 2 24V input required (Sourcing)

E2 Pins 2 & 3 Ground input required (Sinking)

T

T

T

T

Triggering Flow

riggering Flow

riggering Flow

riggering Flow

riggering Flow

A Trigger signal and a Hold signal are provided for

each channel. The channel is triggered On with

discrete inputs or from an external PLC. In order

to get air to flow, the AirTronic unit must have an

active Trigger signal with a non-zero set point.

The set point is set on the display card or from an

external PLC. See "Local Mode" in the "Operation"

section for operation of the display card. The

Trigger signal opens the air supply line by

positioning the needle valve with the stepper motor.

The needle valve position is adjusted until the set

point is achieved. The Control loop may take a few

seconds to position the needle valve and stabilize

the flow.

The Hold signal is needed for applications where

relatively quick On-Off triggering is required. The

Hold signal is designed to work with an atomizer

with an air valve to trigger air source. The Hold

signal works as follows:

• The Atomizer and AirTronic are triggered "On".

• The Hold signal is applied.

• The Atomizer and AirTronic are triggered "Off"."

• The airflow stops because the atomizer air

valve is triggered "Off".

• The AirTronic needle valve remains at the

same position, as it was when the Hold was

applied. The pressure in the channel(s) will

rise to inlet pressure.

• The atomizer is triggered "On". The airflow is

immediate. The system will quickly ramp down

to the preset airflow set when the system was

given the Hold signal.

• The Hold signal is removed. The control loop

positions the needle valve to achieve the set

point flow.

• The AirTronic will now open and fully close

fully close

fully close

fully close

fully close

the needle valve upon trigger signal

ARCHIVE