Troubleshooting guide, Rea iii 100kv automatic applicator - maintenance – Ransburg REA III Auto Applicator 70393 User Manual

Page 36

AA-82-01.3

3 3

3 3

3 3

3 3

3 3

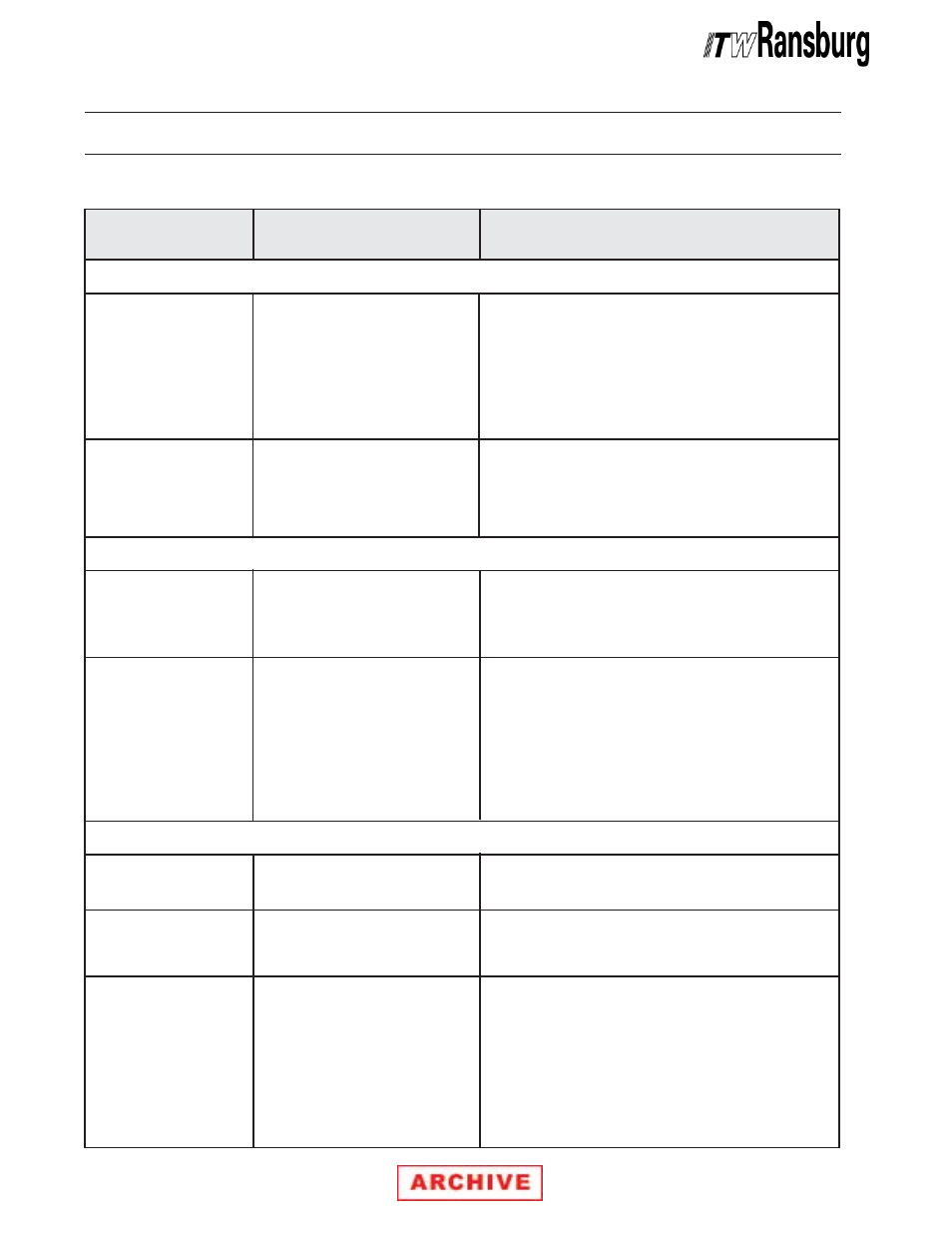

REA III 100kV Automatic Applicator - Maintenance

TROUBLESHOOTING GUIDE

TROUBLESHOOTING GUIDE

TROUBLESHOOTING GUIDE

TROUBLESHOOTING GUIDE

TROUBLESHOOTING GUIDE

General Problem

General Problem

General Problem

General Problem

General Problem

Possible Causes

Possible Causes

Possible Causes

Possible Causes

Possible Causes

Corrective Action

Corrective Action

Corrective Action

Corrective Action

Corrective Action

Pattern Will Not

Pattern Will Not

Pattern Will Not

Pattern Will Not

Pattern Will Not

Shape

Shape

Shape

Shape

Shape

Pattern Heavy At

Pattern Heavy At

Pattern Heavy At

Pattern Heavy At

Pattern Heavy At

One End

One End

One End

One End

One End

A i r

A i r

A i r

A i r

A i r

Fluid

Fluid

Fluid

Fluid

Fluid

A i r

A i r

A i r

A i r

A i r

Fluid: Any at

Fluid: Any at

Fluid: Any at

Fluid: Any at

Fluid: Any at

Rear of Needle

Rear of Needle

Rear of Needle

Rear of Needle

Rear of Needle

Valve Shaft

Valve Shaft

Valve Shaft

Valve Shaft

Valve Shaft

Fluid: Slight at

Fluid: Slight at

Fluid: Slight at

Fluid: Slight at

Fluid: Slight at

Nozzle When

Nozzle When

Nozzle When

Nozzle When

Nozzle When

Trigger is

Trigger is

Trigger is

Trigger is

Trigger is

Released

Released

Released

Released

Released

1. Clogged or faulty fan valve

2. Air passages in applicator

or air feed lines clogged

3. Worn, faulty, or clogged air

nozzle

1. Clogged or faulty air nozzle

2. Clogged or faulty fluid

nozzle

1. Air passages in applicator

or air feed lines clogged

2. Deficient factory air

1. Clogged or faulty fluid

nozzle

2. Clogged fluid passages in

applicator or fluid feed lines

3. Insufficient fluid valve

needle travel

1. Defective valve or valve

spring

1. Packing and/or seals faulty

1. Fluid nozzle not secure

2. Air valve closing before

needle valve

1. Clean, replace, or repair fan valve.

2. Blow out air passages and air feed lines.

3. Clean or replace air nozzle.

1. Clean or replace air nozzle.

2. Clean or replace fluid nozzle.

1. Blow out air passages and air feed lines.

2. Increase air.

1. Flush or replace fluid nozzle.

2. Flush fluid passages and fluid feed lines.

3. Adjust fluid valve needle.

1. Replace valve or valve spring.

1. Replace packing and/or seals.

1. Tighten fluid nozzle.

2. Adjust needle valve travel.

DEFICIENT DELIVERY:

DEFICIENT DELIVERY:

DEFICIENT DELIVERY:

DEFICIENT DELIVERY:

DEFICIENT DELIVERY:

LEAKAGE:

LEAKAGE:

LEAKAGE:

LEAKAGE:

LEAKAGE:

DEFECTIVE SPRAY PATTERN:

DEFECTIVE SPRAY PATTERN:

DEFECTIVE SPRAY PATTERN:

DEFECTIVE SPRAY PATTERN:

DEFECTIVE SPRAY PATTERN: