Ransburg REA III Auto Applicator 70393 User Manual

Page 30

AA-82-01.3

2 7

2 7

2 7

2 7

2 7

REA III 100kV Automatic Applicator - Maintenance

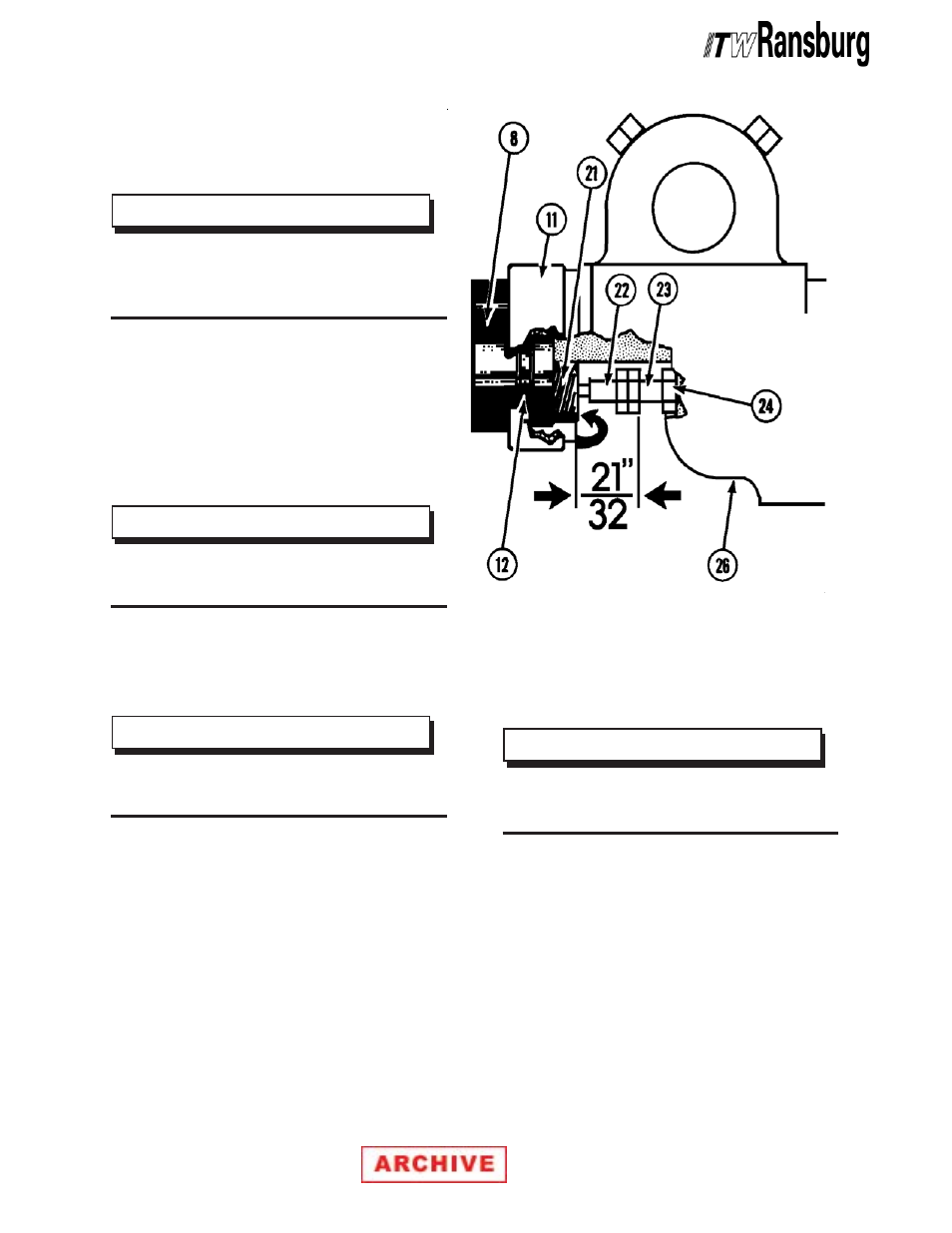

14. Screw packing nut [21] into the chamber and

secure it with the spanner wrench.

>

The packing nut should be tight enough

that shaft [7] slides in and out with firm

resistance.

N O T E

N O T E

N O T E

N O T E

N O T E

15. Screw trigger adjustment nut [33] onto shaft

[7] with the flanged end toward the rear.

16. Screw valve rod extension [23] onto shaft [7]

with the flanged end toward the front.

>

The hexagonal flanges of [22] and [23]

should face each other.

N O T E

N O T E

N O T E

N O T E

N O T E

17. To adjust [22] and [23]:

>

To prevent shaft [7] from rotating, secure

it with a wire through the hole at the rear.

N O T E

N O T E

N O T E

N O T E

N O T E

a. Push shaft [7] fully forward.

b. Measure 21/32-inch (16.6mm) from the

rear face of packing nut [21] to the rear

face of hexagonal flange of the valve rod

extension [23].

c. Secure the nut and rod extension together

at that dimension by rotating nut [22]

rearward until the two will not turn on the

shaft.

d. Tighten the two by holding rod extension

[23] with a 3/8-inch wrench and turning

nut [22] against it with another 3/8-inch

wrench.

>

Fluid nozzle [2] must be firmly in place

(see Step 6).

N O T E

N O T E

N O T E

N O T E

N O T E

Figure 2: Barrel Assembly

Figure 2: Barrel Assembly

Figure 2: Barrel Assembly

Figure 2: Barrel Assembly

Figure 2: Barrel Assembly