Flow control, Hardware flow control, Table 4 - hardware flow control signal functions – AMT Datasouth Codewriter 4500 Series User Manual

Page 32

Data Communications

22

Flow Control

The CodeWriter 4500 Series printers provide two methods to control the flow of data

between the host system and the printer. Hardware or Xon/Xoff flow control is

selected from the Operator Panel.

Hardware Flow Control

The printer uses the CTS, RTS, DTR, and DSR signals during hardware flow

control. Table 4 lists how the printer uses each signal.

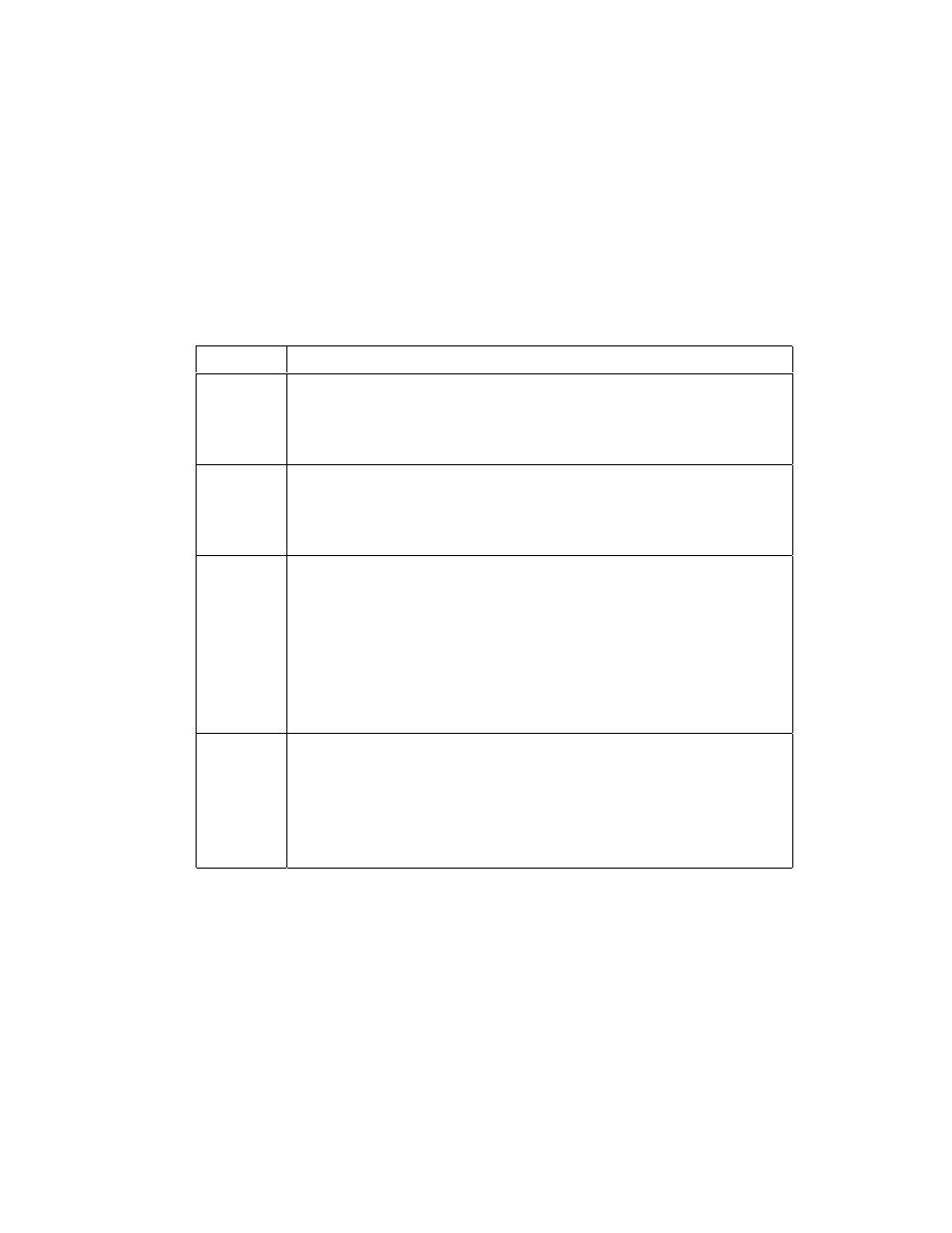

Signal

Function

CTS

Input: The printer monitors the CTS signal for requests

from the host system to send data. This signal must be

asserted ON (Spacing, Positive Voltage) for the printer to

receive data.

RTS

Output: The printer asserts this signal ON (Spacing,

Positive Voltage) whenever the printer is turned on. The

polarity of this signal may be changed from the Operator

Panel.

DTR

Output: The printer asserts this signal ON (Spacing,

Positive Voltage) whenever it is ready to receive data. This

signal controls the flow of data from the host system.

When the printer’s input buffers have reached an almost

full level, the printer de-asserts the signal OFF (Marking,

Negative). In this condition host system should suspend

sending data. The polarity of this signal may be changed

from the Operator Panel.

DSR

Input: The printer monitors the DSR signal to control

sending data to the host system. This signal must be

asserted ON (Spacing, Positive Voltage) for the printer to

send data. The CodeWriter 4500 Series printers depend

on data transmission to the host system for many

applications.

Table 4 - Hardware Flow Control Signal Functions