Sm series, General pump – General Pump SM Owners Manual User Manual

Page 11

GENERAL PUMP

A member of the Interpump Group

SM SERIES

Page 11

The brackets are sized solely for pump lifting and therefore are absolutely not permitted for use of

additional loads.

9. PUMP INSTALLATION

9.1 Installation

The pump must be installed in a horizontal position using the M 16x1.5 threaded support feet. Tightenthe screws with a

torque of 148 ft. lbs. (200 Nm). The base must be perfectly flat and rigid enough as not to allow bending or misalignment

on the pump coupling and axis/transmission due to torque transmitted during operation.

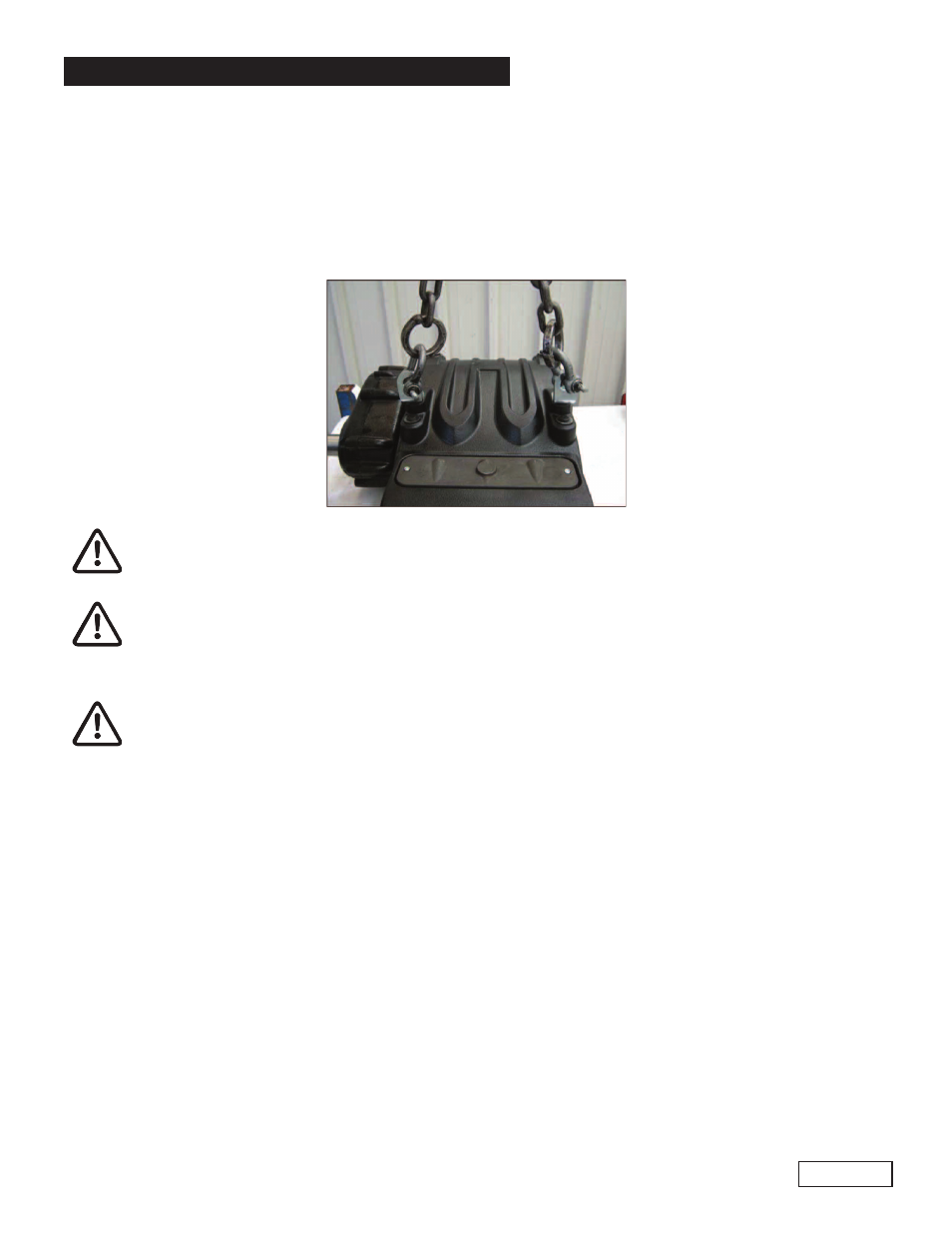

Two lifting eyebolts are mounted on the pump for easy installation, as per the figure below.

Ref 300893 Rev.A

06-12

Replace the oil filling hole closing service plug positioned on the rear casing cover with the plug

with oil dipstick. Check the correct quantity of oil. The dipstick must always be reachable, even when

the unit is assembled.

The pump shaft (PTO) should not be rigidly connected to the propulsor unit

The following typed of transmissions are recommended:

• Flexible joint

• Cardan-shaft (comply with manufacturer’s Max. recommended working angles)

• Belts. For proper application consult with our Customer Service Department