Finish Thompson AC 4 & 5 HORIZONTAL SERIES User Manual

Page 2

2

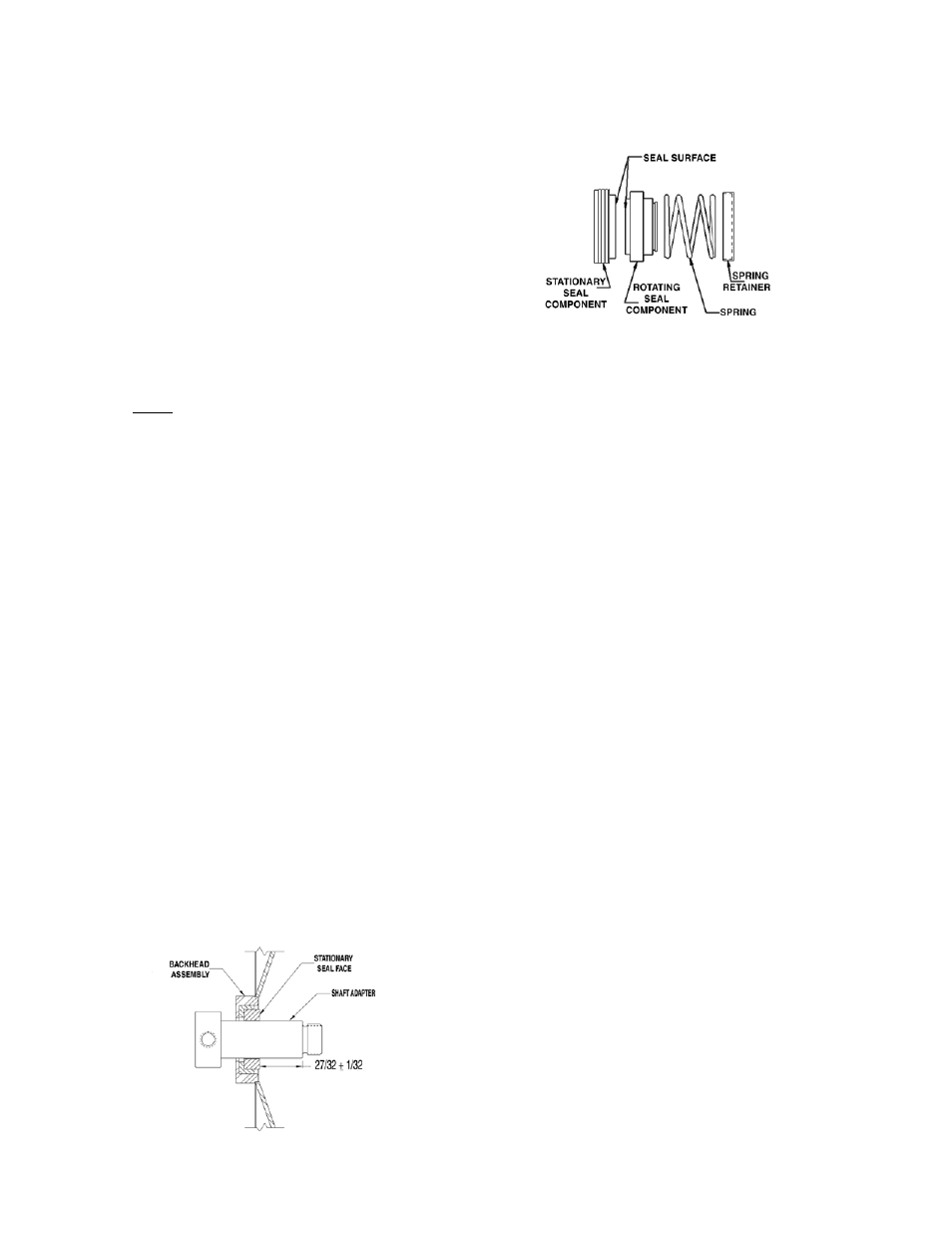

5. Lubricate the inside of the rotating seal component with a chemically

compatible lubricant and carefully slide it over the shaft adapter

with a rotating face pointing at the motor (as shown in figure 3).

NOTE: Rotating seal must be completely seated against the station-

ary seal face.

6. Place the seal spring and spring retainer over the shaft adapter.

NOTE: To prevent spinning the impeller off in case the motor is

wired for incorrect rotation, it is recommended to coat the shaft

adapter threads with Loctite Threadlocker #262.

7. Holding the motor shaft firmly, thread the impeller onto the shaft

adapter until it stops at the adapter shoulder.

8. Lubricate the housing o-ring (item 3) with chemically compatible

lubricant, and install onto the backhead. Install the impeller hous-

ing (item 1), the V-clamp (item 2), and the nut onto the V-clamp

stud. Verify the V-clamp stud and housing discharge orientation

and tighten the V-clamp. Firmly tap the V-clamp to seat it in several

places and retighten the V-clamp nut.

9. Rotate the motor shaft by hand to verify there is no rubbing. Replace

the motor fan and fan cover. Reinstall the pump into the system.

TROUBLESHOOTING

NO OR INSUFFICIENT FLOW

1. Pump not primed.

2. Closed valve.

3. Viscosity too high.

4. Air leaks in suction piping.

5. Discharge head higher than anticipated.

6. Suction lift too high or insufficient NPSH.

7. Check for clogged suction line.

8. Motor wired for wrong rotation.

INSUFFICIENT PRESSURE

1. Air or gas in liquid.

2. Impeller diameter too small.

3. Discharge head higher than anticipated.

4. Motor speed insufficient (too low) or motor rotation incorrect.

LOSS OF PRIME

1. Leaking suction line.

2. Foot valve or suction opening not submerged enough.

3. Foot valve too small or leaking.

4. Air or gas in liquid.

5. Foreign matter in impeller.

EXCESSIVE POWER CONSUMPTION

1. Head lower than rating. Excessive flow.

2. Specific gravity or viscosity of liquid is too high.

EXCESSIVE VIBRATION

1. Loose piping or bolts.

2. Pump cavitating from improper suction or feed.

Figure 2

Figure 3

MAINTENANCE

DISASSEMBLY

1. Disconnect power. Remove electrical wiring.

2. Close the suction and discharge valves and disconnect all piping.

3. Loosen and remove the nut on the V-clamp stud. Remove the V-

clamp (item 2) and the impeller housing (item 1). Note V-clamp

stud and discharge spout location for reassemble alignment.

4. Remove the motor fan cover and fan. Secure the motor shaft to

prevent it from turning, and unthread the impeller.

NOTE: Shaft adapter threads are coated with Loctite Threadlocker

#262 to prevent the impeller from spinning off if the motor is inad-

vertently wired for incorrect rotation. If necessary follow Loctite’s

recommendations for loosening the threadlocker #262.

5. Remove the seal spring retainer, spring, and the rotating seal

component from the shaft adapter. Remove the backhead (item

7) from the pump. Remove the stationary part of the seal from

the backhead.

6. If the motor is being replaced, proceed to step 7. If the seal is being

replaced, do not loosen or remove the shaft adapter (item 6) from

the motor shaft. Proceed to step 3 of the reassembly instructions

7. Remove the four bolts holding the motor adapter/mounting plate

assembly (items 8 & 15) to the motor and remove the motor

adapter. Loosen all four setscrews and remove the shaft adapter.

8. Inspect all parts for wear and replace as required. Note the fin-

ish on the shaft adapter where the rotating seal boot is located. If

damaged or not smooth, replace the shaft adapter.

REASSEMBLY

1. Install the shaft adapter (item 6) onto the motor shaft. Be sure one

of the setscrews is protruding into the motor shaft keyway slot, but

do not tighten any setscrews yet.

2. Install the motor adapter/mounting plate assembly (8 & 15) with

setscrews access slots at 12 and 6 location, and tighten all four

bolts.

3. Lubricate the outer boot on the stationary part of the seal with a

chemically compatible lubricant, and press into the backhead (item

7) until it is fully seated. The polished seal surface should be facing

away from the motor.

NOTE: To keep the polished surface of the seal face clean, use a

piece of cardboard to protect the seal face during installation.

4. Insert the backhead (item 7) into the motor adapter (item 8) bore

and press into place.

If the shaft adapter was not loosened or removed, go to step 5. If

replacing the shaft adapter, firmly hold the backhead toward the

motor, and adjust the shaft adapter until the shoulder is .843 (27/32)

inches from the stationary seal face (see figure 2). Tighten all four

setscrews with a T wrench through the access slots in the motor

adapter.