Finish Thompson GP22/32 SERIES User Manual

Page 3

SPeCIAL PIPINg SITuATIONS

Suction Lift

1. Install a priming chamber on the feed side of the pump or appropri-

ate piping on the discharge for priming the pump.

2. Install a foot valve on the bottom of the suction piping to maintain

a prime to the pump.

CAuTION: Suction prime must be maintained at all times. Running

the pump dry will cause damage to pump components. To protect

the pump if prime is lost, use a pressure switch on the discharge,

a vacuum switch on the suction, or a motor minder to monitor

motor current draw.

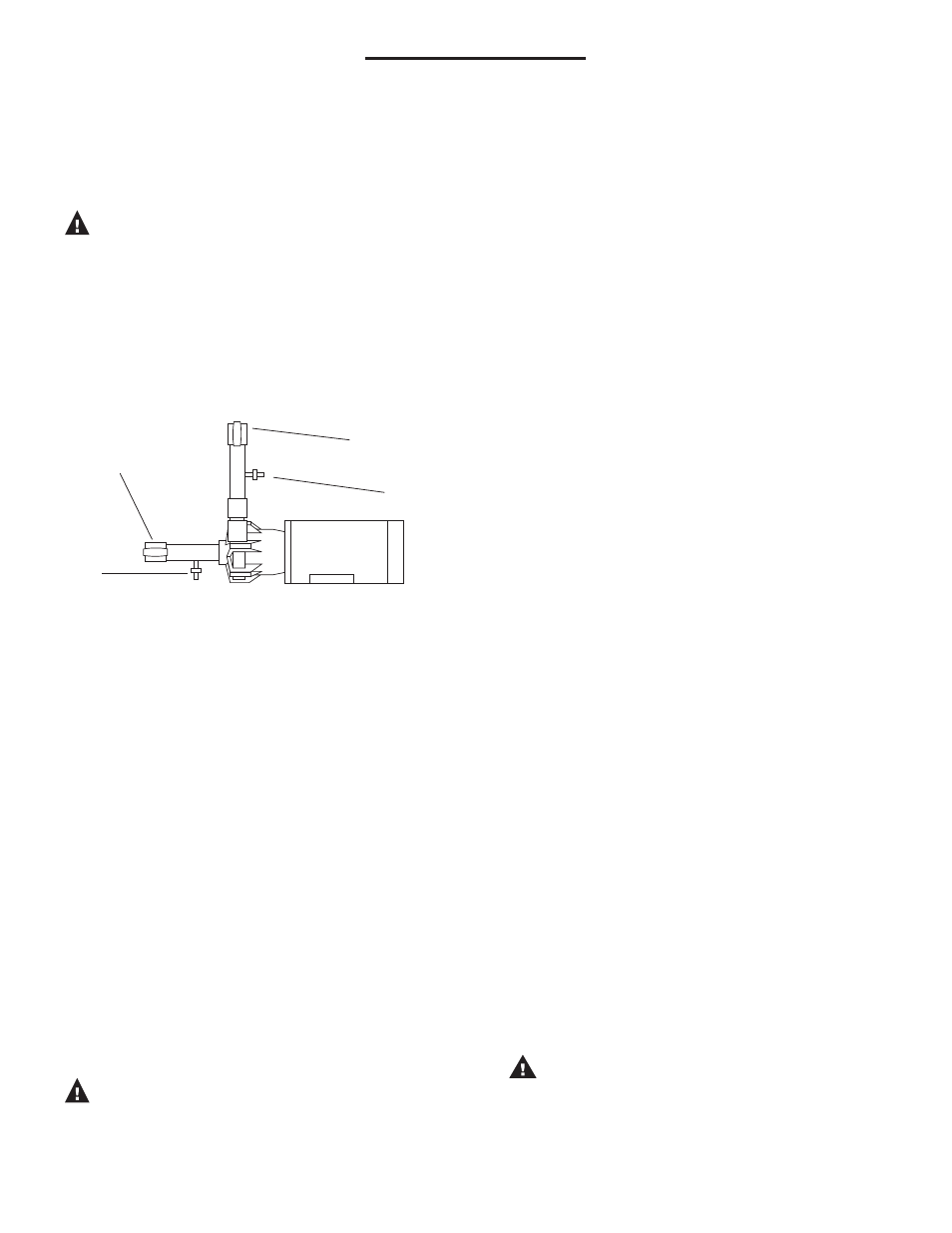

PuMPINg LIQuIdS whICh MAY SOLIdIFY Or CrYSTALLIze

Add a flush system to the pump’s piping to prevent accumulation of

material inside the pump. Install water inlet and outlet valves as shown

in Figure 1. Refer to the “Operation” section of these instructions for

the flush procedure.

eLeCTrICAL CONNeCTIONS

1. Install the motor according to NEC requirements and local electrical

codes. Motor should have an overload protection circuit.

2. Wire the motor for clockwise rotation when facing the fan end of

the motor.

3. To verify correct rotation of the motor:

a. Install the pump into the system.

b. Fully open the suction and discharge valves.

c. Allow fluid to flow into the pump. Do not allow the pump

to run dry.

d. Jog the motor (allow it to run for only one to two seconds)

and observe the rotation of the motor fan. Refer to the

directional arrow on the pump if needed.

NOTe: A pump running backward will run but at a greatly reduced

flow and pressure.

OPerATION

FLOOded SuCTION SYSTeMS

1. Fully open the suction and discharge valves.

2. If a cooling collar is used, turn on the cooling water.

3. Start the pump and verify liquid is flowing. If there is no liquid

flow, refer to the “Troubleshooting” section of these instructions.

4. Adjust the flow rate and pressure by regulating the discharge valve.

CAuTION: Never attempt to adjust the liquid flow with the suction

valve. Limiting the suction will result in damage to the pump's

components.

SuCTION LIFT SYSTeMS

1. Fully open suction and discharge valves.

2. If a cooling collar is used, turn on the cooling water.

3. Prime the pump by filling the priming chamber. Allow time for any

trapped air in the suction piping to escape.

4. Start the pump. Adjust the flow rate and pressure by regulating

the discharge valve.

CAuTION:

Never attempt to adjust the liquid flow with the suction

valve. Limiting the suction will result in damage to pump compo-

nents.

FLuSh SYSTeMS

1. Fully close the suction and discharge valves.

2. Connect the water supply to the water inlet valve and connect a

drain hose to water outlet valve.

3. Turn on the water supply and open the inlet and outlet valves. Flush

the system until the pump has been cleared of any material buildup

(approximately 5 minutes).

4. Close the inlet and outlet valves and turn off water supply.

SeALS

SeAL reMOvAL ANd INSPeCTION

1. Disconnect the piping and electrical power from the pump.

2. Disassemble the pump from the motor adapter.

a. Remove the six hex-head cap screws from the impeller

housing. The impeller housing will loosen if gently tapped at

the discharge outlet.

b. Remove the protective shroud from the motor adapter.

c. While preventing the motor shaft from moving (insert a screw-

driver into the motor’s fan), unscrew the impeller cap with o-ring

and socket head bolt (Items #4,16 and 13) in a counterclockwise

rotation. Use large flathead screw driver and 5/16" hex key.

Remove the impeller, seal, cooling collar (if applicable) and

housing cover as one assembly from the motor shaft.

Note: For pumps using 90, 100/112 motor adapters, leave the

shaft adapter secured to the motor shaft.

3. Remove the seal for inspection.

a. Lubricate the impeller’s shaft with a rubber lubricant emul-

sion or soapy water to allow the seal to slide easier.

Note:

Never use a petroleum product for lubrication.

Doing so will effect the seal elastomer’s performance

after reassembly.

b. If no cooling collar is present, carefully remove the retaining

ring that holds the rear of the seal. If equipped with a

cooling collar, carefully slide the cooling collar off of the

impeller’s shaft.

• With single bellows or multi-spring seals, a retain-

ing ring holds the seal in place. Carefully remove

the retaining ring. Loosen the four (4) set screw on

the multi-spring seal.

• With double seals, the cooling collar holds the seal

in

place.

CAuTION: The seal’s spring is compressed and under

pressure. Use care when removing.

c. Remove the seal’s spring. Grasp the rotating head of the

seal by hand and twist to remove from the impeller’s shaft.

d. Remove the housing cover from the impeller.

e. Press the ceramic stationary seat portion of the seal out of

the housing cover.

3

Figure 1

Suction Valve

Water

Outlet Valve

Discharge Valve

Water Inlet Valve