Finish Thompson VKC5.5,6,6H,7,8,10 SERIES User Manual

Page 5

5

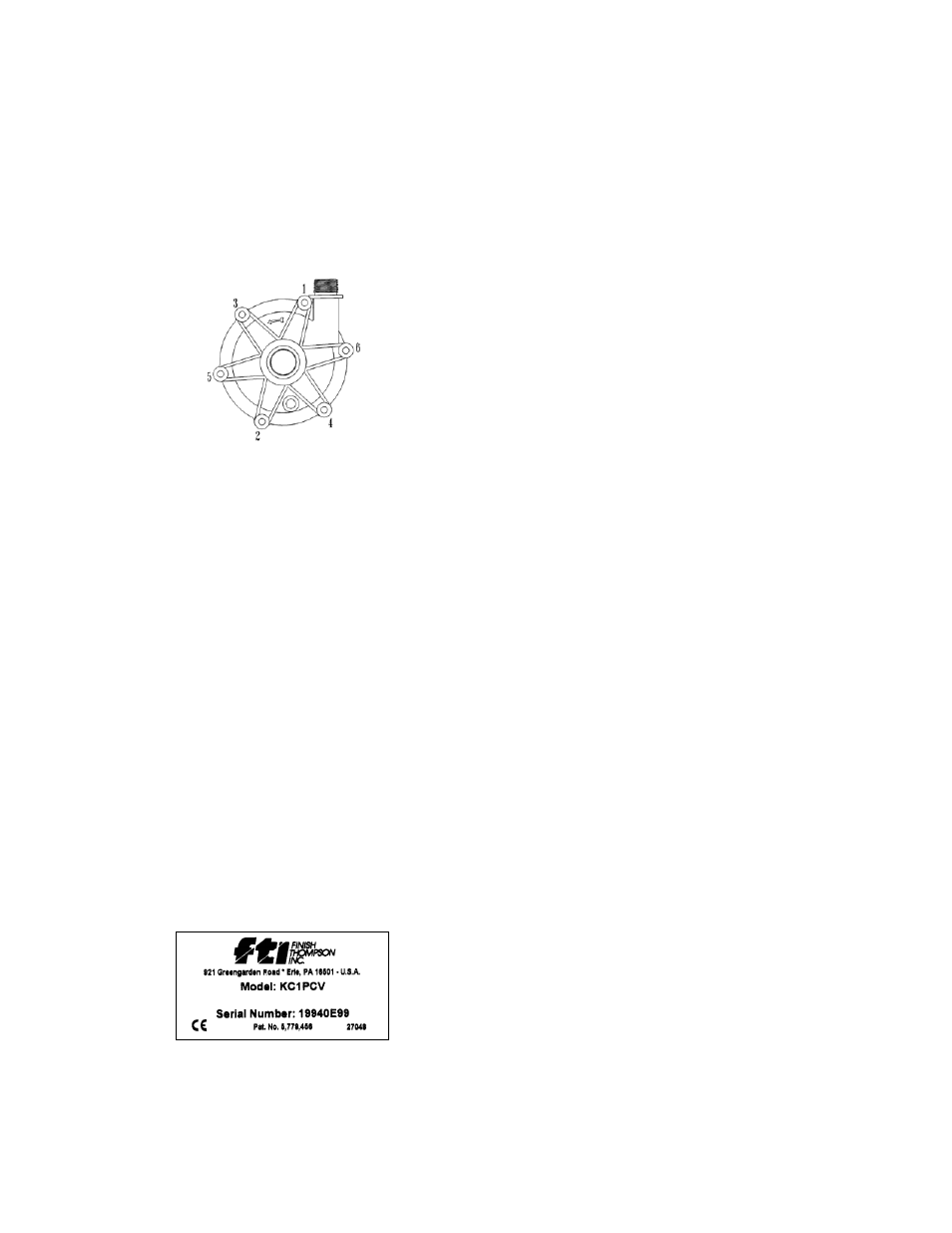

11. Reassemble the wet end by placing the impeller (items 18 and 19) onto

the ceramic shaft in the column housing adapter (item 15). Install the

housing o-ring (item 16), and lubricate with a compatible lubricant.

Align the marks made on the housing (item 21) and the column hous-

ing adapter (item 15) during disassembly. Install the impeller housing

(item 21) onto the column housing adapter taking care not to dislodge

the o-ring. Align the bolt holes and install the six mounting screws

(item 22). Use a PTFE thread lubricant on the PVDF screws. Following

the pattern in Figure 5, carefully tighten using a screwdriver. Do not

over- tighten the screws (recommended maximum torque is 25 in-lbs.)

Reach into the suction and spin the impeller with your finger to verify

it is not rubbing or binding.

Figure 5

12. Slide the locking ring over the end of the column extension with the

smaller inside diameter side toward the motor. Lubricate the column

rings (item 12) with a compatible lubricant and install the “wet end”

by threading it on until the flats line up. Pull the locking ring toward

the pump end and snap it in place locking the two sections together.

13. Rotate the motor fan by hand to verify nothing is rubbing or binding. Reinstall

the pump into the system according to the installation instructions.

GENERAL NOTES

1. Do not pump liquids containing metal fines.

2. If magnets decouple, stop the pump immediately. The rare earth

magnets used in this pump are more resistant to demagnetization,

but operating the pump with the magnets decoupled will eventually

weaken the magnets.

3. Plastic pumps will expand and contract with temperature so periodically

check and hand tighten screws.

4. Use a chemically compatible thread lubricant on threads of column

sections.

5. The setting of the drive magnet dimension is critical. Failure to prop-

erly set the dimension may result in decoupling or damage to pump

components.

6. An information sticker is attached to the motor adapter section. The

first line is the model number, the second is the serial number. See

Figure 6.

Figure 6

7. The pump will contain various numbers of shaft bearings (item 28)

based on the length of the pump as follows:

12” pump

= (2) shaft bearing

18” pump

= (2) shaft bearings

24” pump

= (3) shaft bearings

30” pump

= (4) shaft bearings

36” pump

= (5) shaft bearings

42” pump

= (6) shaft bearings

48” pump

= (7) shaft bearings

54” pump

= (8) shaft bearings

60” pump

= (9) shaft bearings

8. Due to the hermetically sealed design, the pump will displace liquid

as follows:

12” pump = approximately 1 gallon (3.78 liters)

Add approximately 1 quart (.95 liter) per column section.

E.G. 24” pump = 1-1/2 gallons (4.73 liters)

9. 12” pumps do not have column extensions.