Instructions, Owner service, Tractor requirements and preparation – Farm Star SRTC-406A User Manual

Page 19: Caution, Warning, Danger, Safety . . . you can live with it, Continued) blade servicing, Shear bolt replacement, Important

25

18

TRACTOR REQUIREMENTS

AND PREPARATION

The models STTC-404A, SRTC-405A and SRTC-406A

Standard Duty Cutters require a Category I 3-pt. hitch

tractor of at least 20 horsepower or up to 45 horsepower

and equipped with a 540 rpm PTO (power takeoff) in

good working condition.

It is recommended that only tractors with wide front

axles be used with this cutter. Tricycle front wheel

arrangements are inherently unstable and tractor

roll-over accidents are more likely to occur.

The tractor also needs lift arm stabilizer bars or sway

blocks to control side movement of the cutter.

Check the tractor’s 3-pt. hydraulic lift system. Refer to

your tractor operator’s manual or dealer for any adjust-

ments necessary to put the hydraulic system in good

working order. (I&T shop manuals will list most specifica-

tions and adjustment instructions - available from most

farm equipment dealers.)

Be sure tires and rims are in good condition. Inflate tires

to the proper recommended air pressure.

All tractors that are not equipped with a “live” power

takeoff (PTO) need to be equipped with an over-running

PTO clutch attachment.

Check the tractor master shield over the PTO stub shaft.

Make sure it is in good condition and fastened securely

to the tractor. Purchase a new shield if old shield is

damaged or missing. (You may have to use a tractor

salvage yard for replacement parts on older tractors.)

Power unit must be equipped with ROPS or ROPS cab

and seat belt. Keep seat belt securely fastened. Falling

off power unit can result in death from being run over or

crushed. Keep foldable ROPS systems in “locked up”

position at all times. Contact your local dealer for a ROPS

for your tractor.

CAUTION!

Be sure your tractor is in good condition. Read all

the safety precautions and make sure all tractor

operators are familiar with the safety rules of

operation.

Figure 1. Tractor Stability

WARNING!

When using the unit, a minimum 20% of tractor and

equipment weight must be on tractor front wheels.

Without this weight, tractor could tip up, causing

possible loss of control and possible personal injury

or death. The weight may be attained with a front end

loader, front wheel weights, ballast in tires or front

tractor weights. When attaining a minimum 20% of

tractor and equipment weight on the front wheels,

you must not exceed the ROPS weight certification.

Weigh the tractor and equipment. DO NOT GUESS

OR ESTIMATE!

WARNING!

A heavy load can cause instability in driving a

tractor. Make sure the front of the tractor is properly

counterbalanced with weights. Always drive slowly

– especially around turns. An unstable tractor could

steer badly and possibly tip over, causing injury or

death.

DANGER!

FOR AGRICULTURAL USE ONLY!

When this equipment is operated in populated areas

or other areas where thrown objects could injure per-

sons or property, full chain or rubber shielding

(which is designed to reduce the possibility of

thrown objects) must be installed. If this machine is

not equipped with full chain or rubber shielding,

operation must be stopped when anyone comes

within several hundred feet.

NOTE: Optional chain shield kits are listed on page

23.

SAFETY . . .

YOU CAN LIVE WITH IT!

INSTRUCTIONS

The operator is responsible for the safe operation of this

cutter. The operator must be properly trained. Operators

should be familiar with the cutter and tractor and all safe-

ty practices before starting operation. Read the safety

rules and safety signs on pages 5-17.

This standard duty cutter is designed for grass and

weed mowing and shredding.

Recommended mowing speed for most conditions is

from two to five mph.

OWNER SERVICE

(continued)

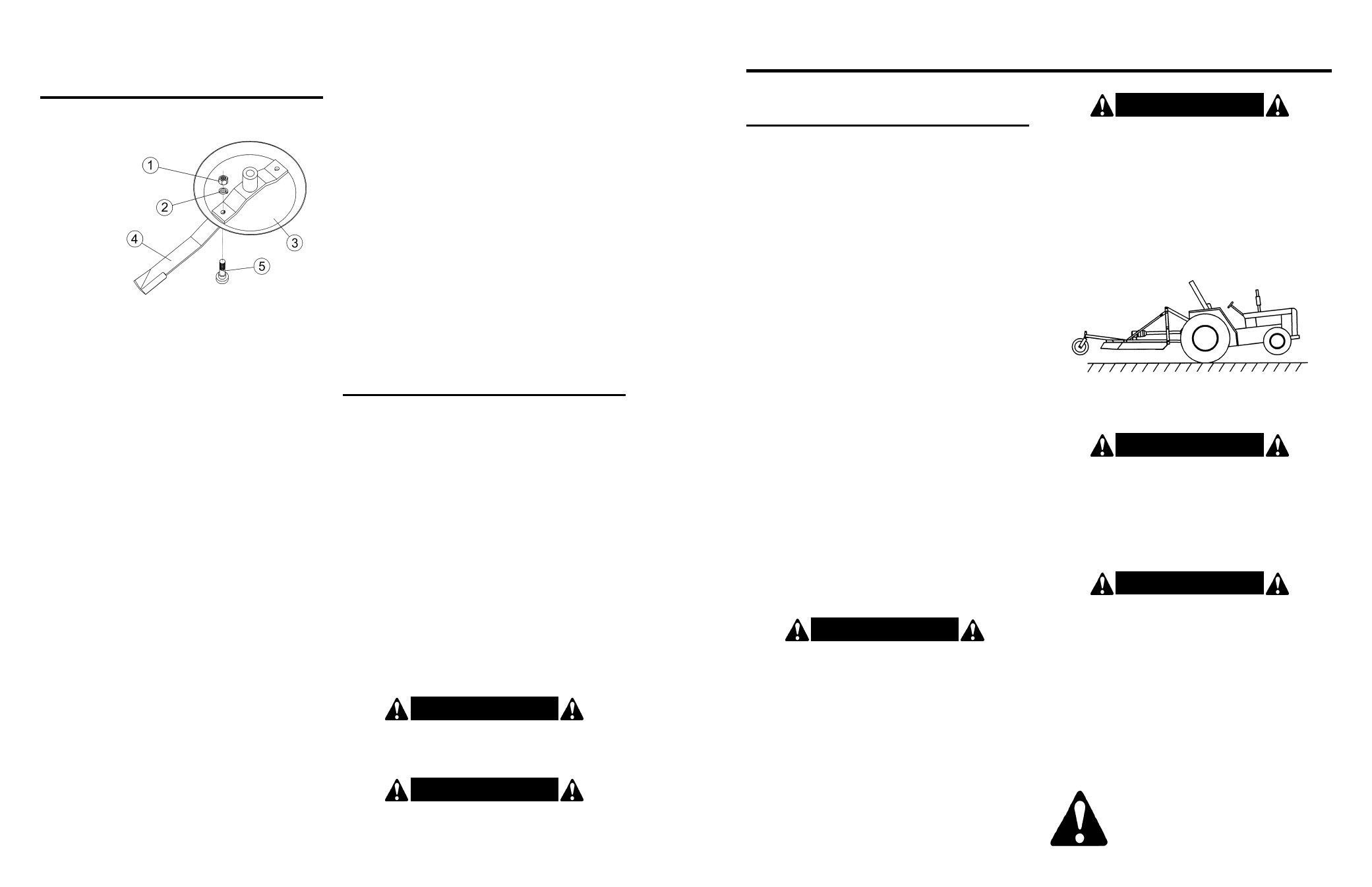

BLADE SERVICING

BLADE REMOVAL

(Figure 7)

1. Nut, Blade Lock

2. Lockwasher

3. Blade Pan

4. Blade

5. Bolt, Blade

Figure 7. Blade Installation

SHEAR BOLT REPLACEMENT

Remove driveline shield bell.

IMPORTANT: Avoid shear bolt failure at start up by

engaging the PTO slowly at low engine rpm.

Make sure the input shaft of the gearbox is greased.

This reduces the chance of the PTO shaft yoke from

galling to the input gearbox shaft if the shear bolt should

break.

Rotate driveline to align holes in yoke and shaft. Install

shear bolt and secure with locknut. Replace driveline

shield bell.

If necessary remove sheared bolt with hammer and

punch and realign holes in yoke and shaft.

Disconnect driveline from tractor PTO.

It is necessary to gain access to bottom side of cutter

for blade removal. Raise cutter and block securely.

Align crossbar (3) with blade access hole in the cutter

deck. Remove nut (1) and lockwasher (2) then carefully

drive bolt (5) out of crossbar.

Insert blade bolt (5) through blade, align key on blade

bolt with keyway in blade beam and push blade bolt

through blade beam. Insert lockwasher (2) and nut (1)

through blade access hole in the cutter deck, install on

bolt (5) and tighten to 350 lbs.-ft.

Repeat for opposite blade.

Sharpen both blades at the same time to maintain bal-

ance. Follow original sharpening pattern. Do not sharpen

blade to a razor edge, but leave at least a

1

/

16

” blunt edge.

Do not sharpen back side of blade.

Rotate blade beam (3) and repeat for opposite blade.

Always replace or sharpen both blades at the same

time.

Inspect blade bolt (5) for nicks or gouges; replace if any

are found. Insert bolt through blade. Blade should swivel

on bolt. Determine cause if it does not and correct.

Align blade beam (3) with blade access hole in the cut-

ter frame. Apply a liberal coating of Never Seez

®

or equiv-

alent to blade bolt and blade beam hole. Make sure blade

is offset away from cutter.

Never Seez is a registered trademark of the

Never Seez Corporation.

WARNING!

FAILURE TO USE CORRECT SIZE SHEAR BOLT

MAY CAUSE PERSONAL INJURY OR DEATH.

WARNING!

FAILURE TO INSTALL RETAINING CLIP WILL

ALLOW DRIVELINE TO SWING FREELY IF BOLT IS

SHEARED CAUSING POSSIBLE INJURY OR DEATH.

IMPORTANT

If blade bolt (5) is seized in blade beam and extreme

force will be required to remove it, support blade

beam from below to prevent gearbox damage.

IMPORTANT

When sharpening blades, grind each blade the same

amount to maintain balance. Replace blades in pairs.

Unbalanced blades will cause excessive vibration

which can damage gearbox bearings. Vibration may

also cause structural cracks to cutter.

IMPORTANT

Always use approved

1

/

2

” NC x 3” grade 2 shear bolt

as a replacement part. Using a hardened bolt or

shear pin may result in damage to driveline or

gearbox.

IMPORTANT

Blade beam rotation is counter-clockwise when

looking down on cutter. Be sure to install blade cut-

ting edge to lead in counter-clockwise rotation.

BLADE SHARPENING