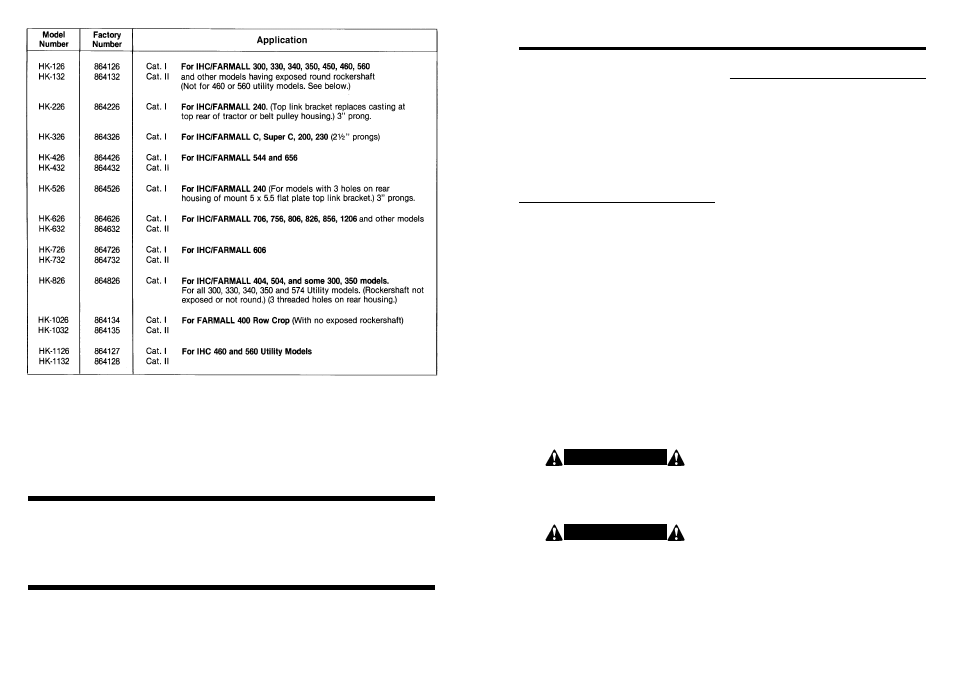

Farm Star HK-1132 User Manual

Page 8

7

4

T R A C T O R P R E PA R AT I O N

Be sure tires and rims are in good condition. Inflate tires

to the proper recommended air pressure.

Check the tractor’s hydraulic system. Refer to your

tractor operator’s manual or dealer for any adjustments

necessary to put the hydraulic system in good working

order. (I&T shop manuals will list most specifications and

adjustment instructions – available from most farm

equipment dealers.)

Check the shield over the PTO stub shaft. Make sure it

is in good condition and bolted securely to the tractor.

Purchase a new shield if old shield is damaged or

missing. (You may have to use a tractor salvage yard for

replacement parts on older tractors.)

It is recommended that a ROPS (Roll-Over Protection

Structure) be installed on all tractors. Contact your local

dealer for ROPS for your tractor.

Check the threaded holes that go into the rear tractor

housing and make sure the threads are in good condition

and that the holes are clean.

NOTE: The hole in the differential housing may have

painted cork plugs in them. It is necessary to remove the

cork and clean the holes.

A S S E M B LY

For instruction reference, the terms front or rear are

based on the operator facing forward on the tractor, thus

front is toward the front of the tractor and the rear is to

the rear of the tractor.

It is suggested that all the instructions be read before

beginning assembly.

Check the view of the toplink bracket for your tractor

model in this manual to see the relationship of the parts.

The prong assemblies slip into the prong sockets on

your tractor. If you have ordered a kit for a 32” drawbar

spacing (Category II), then there is a right-hand and a

left-hand prong assembly.

The 2-way ball sockets on the end of the prongs will

allow you to connect to either Category I or Category II

implements. If the drawbar or implement you mount has

Category I (

7

/

8

” dia.) pins, then make sure the balls are

turned so that the

7

/

8

” dia. holes are used.

IMPORTANT: If the larger 1

1

/

8

” dia. holes are used

with the smaller

7

/

8

” dia. pins, the ball holes will wear

rapidly in an uneven pattern and make the entire

ball socket eventually unusable.

Fig. 2 for HK-126 & HK-132

Remove the top link clevises from the top link bracket.

Place the top link clevises over the tractor’s exposed

rocker arm shaft and pivot them until they are parallel

with the ground. Then slide the top link bracket assembly

between the clevises and bolt back together. Attach the

top link to the top link bracket.

NOTE: IHC/Farmall model 300 and 350 tractors were

made with at least three different hitch configurations.

Some have the exposed rockershaft, some have holes

drilled and threaded in the rear differential, and the 300

rowcrop models cannot be fitted with a toplink bracket.

Check your tractor for which adapter kit is required.

NOTE: A few IHC model 460 and 560 tractors with an

exposed rockershaft were made with a larger 2

1

/

8

”

diameter rockershaft (normal rockershaft diameter is 2.0

inches). If you have one of these tractors with the larger

2

1

/

8

” shaft, contact Worksaver, Inc. and ask for a pair of

860129 clevis brackets that will accommodate the larger

shaft diameter.

Fig. 3 for HK-226 & HK-326

Remove the belt pulley shaft cover, taking care not to

damage the gasket. If the gasket is damaged, make a

new one or use a good gasket sealing compound. Place

the top link bracket against the gasket and housing of the

tractor and secure it in place with the

7

/

16

” - 14 x 4

1

/

2

” bolts

and

7

/

16

” lockwashers provided. Attach the top link to the

top link bracket using the pin and linchpin provided.

The 2 pt. to 3 pt. adapter kits are designed for

International Harvester/Farmall tractors that are

equipped with the IHC “fast-hitch.”

These kits allow 3 pt. equipment to be used on tractors

that were for 2 pt. fast hitch equipment only.

NOTE: International Harvester Company (IHC) made

the “fast-hitch” for a wide variety of tractors and in a few

cases made variations on the hitch for the same model

tractors.

NOTE: Cat. I = 26” Spacing

Cat. II = 32” Spacing

I N S T R U C T I O N S

Be sure your tractor is in good condition and

properly equipped with counterweights. Read all the

safety precautions and make sure all tractor

operators are familiar with the safety rules of tractor

operation.

C A U T I O N !

If an air hose is used to blow any loose rust or dirt

from the holes, be sure safety glasses are used to

prevent particles from entering an eye.

C A U T I O N !

O B E Y A L L

S A F E T Y WA R N I N G S !