A. platform cornering – Fairbanks Portable Axle Load Scale User Manual

Page 9

A. Platform Cornering

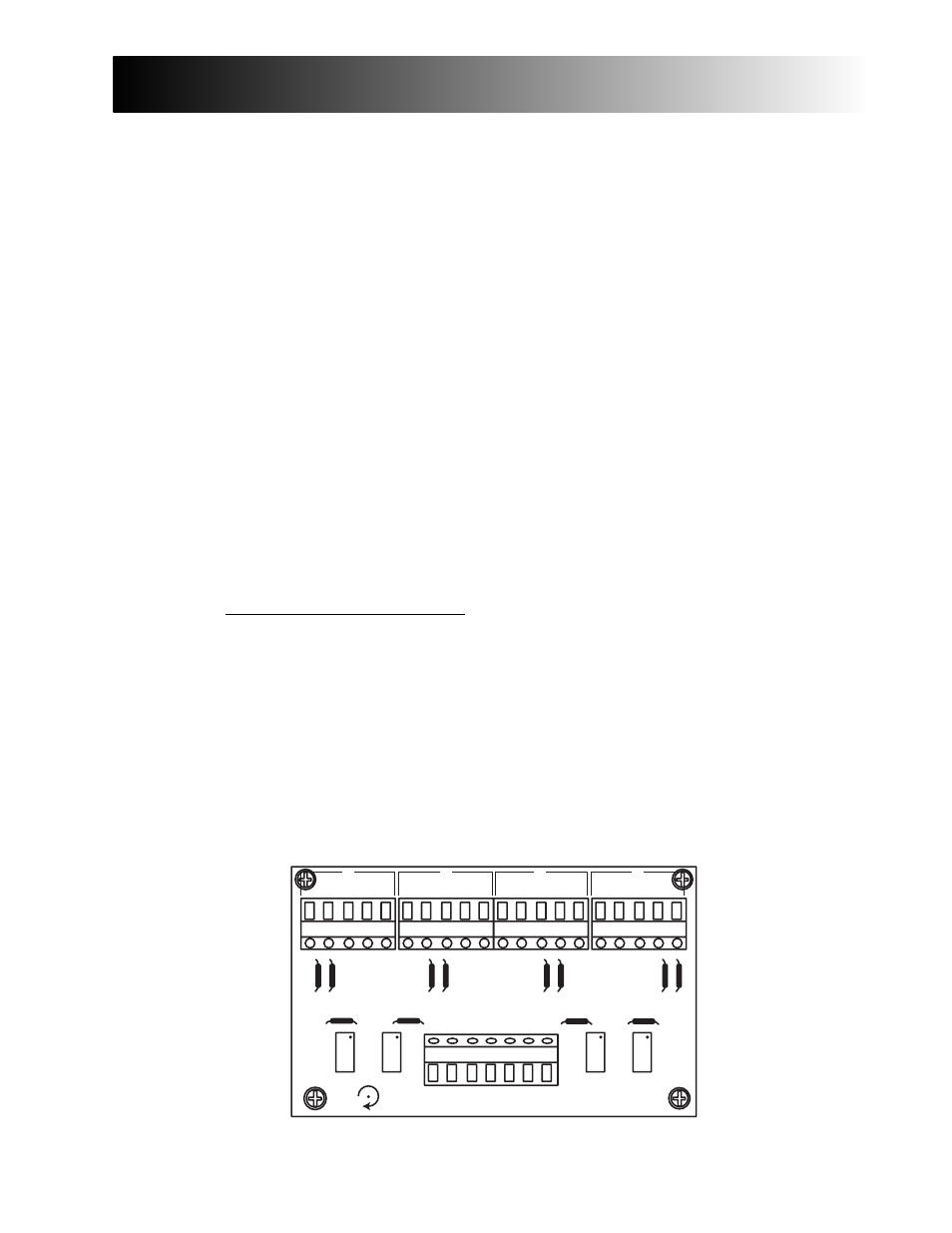

Analog Interface (Junction Box 67171):

1.

Adjust the analog indicator to the platform. First, ensure all corners are within

one (1) division of each other at 25% of rated capacity. Follow the appropriate

indicator service manual for indicator calibration.

a.

Perform a course platform calibration close to the actual weight.

b.

Identify the platform corner numbers.

c.

Place a concentrated weight (25% of platform capacity) on corner 1. Move it

to corner 2, corner 3 and corner 4, noting the displayed reading on each

corner.

d.

If corners require adjustment: Place the concentrated weight on the corner

displaying the lowest weight and use the appropriate potentiometer to

change the displayed weight to read the same as the highest reading by

turning the potentiometer clockwise (CW). Repeat this procedure while

rechecking all corners until there are no errors. Perform a zero reference

check with a unloaded platform, then repeat the corner test to ensure all

readings are the same before proceeding.

04/05

9

50784 Issue 1

Section 33: Calibration

4

4

3

3

2

2

1

1

+ SIG

- SIG

- SEN

- EXC

+ SEN

- EXC

SHLD

+E -E SH -S +S

+E -E SH -S +S +E -E SH -S +S

+E -E SH -S +S

96141