Ex d iic t4 gb, Ex tb iiic t135°c db, Cenelec / iec – Fire Fighting Enterprises Talentum IR3 Flame Detector User Manual

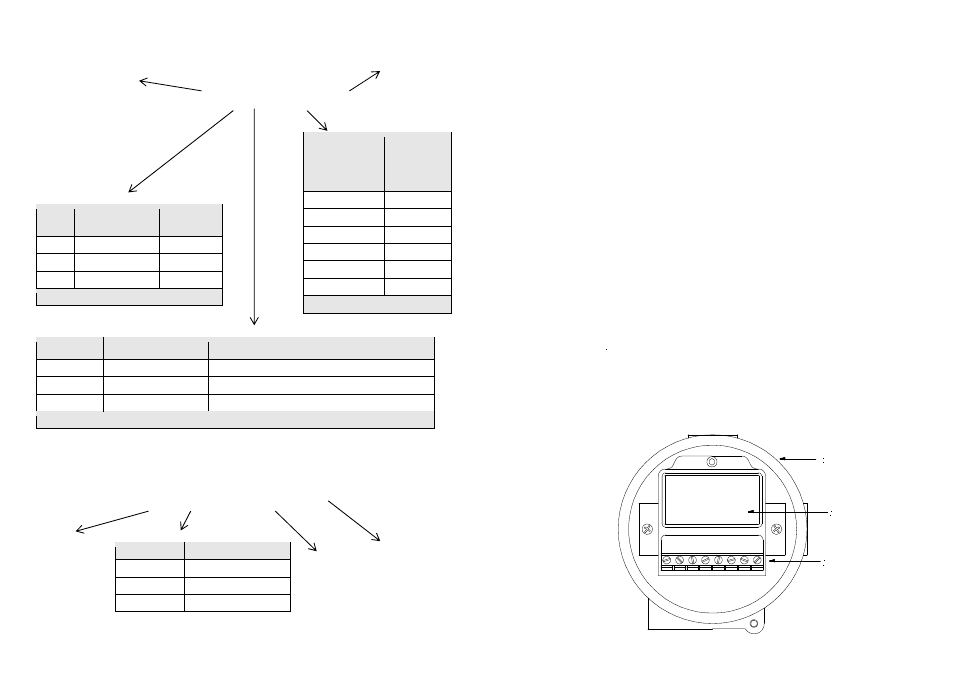

Page 4: Health and safety at work act, Installation, Enclosure with front cover removed

4

CENELEC / IEC

Ex d IIC T4 Gb

Table 2 Type of Protection Codes

Table 3 Temperature Classification

Table 4 Subdivisions of Group II Gases

Ex tb IIIC T135°C Db

Temperature

Class

Referred to

ambient of

-20°C to +40°C

Maximum

Surface

Temperature

T6 85°C

T5 100°C

T4 135°C

T3 200°C

T2 300°C

T1 450°C

Detectors approved to T4.

Code

Type of

Protection Code

Equipment

Category

ia Intrinsic

safety

1

ib Intrinsic

safety

2

d

Flameproof 2

These Flame Detectors are approved ‘d’.

Gas Group

Representative Gas

Other Gases, Liquids, Vapours

IIC

Hydrogen

Acetylene, Carbon Disulphide

IIB

Ethylene

Diethyl ether, Tetrafluoroethylene

IIA

Methane

Butane, Methanol, Petroleum, Propane, Styrene

These Flame Detectors are approved IIC for listed gases in EN 60079-0.

Dust Group

IIIC

Conductive Dust

IIIB

Non-conductive Dust

IIIA

Combustible Flyings

Equipment

Protection

Level

Gas (EPL)

[See EN60079-26]

Explosion Protection

symbol

Equipment

Protection

Level

Dust (EPL)

[See EN60079-26]

Maximum

External

Surface

Temperature

Dust

Protection

Concept

[See EN61241-1]

9

FLAME SENSOR

ELECTRONIC MODULE.

FLAME SENSOR

CONNECTION TERMINALS.

Exd HOUSING WITH

FRONT REMOVED.

Health and Safety at Work Act

In the UK all equipment must be installed and disposed of (as required) within the legislative

requirements of the Health & Safety at Work Act 1974.

Installation

No modification should be made to the enclosure without reference to the manufacturer as

unauthorised modification to an approved enclosure will invalidate the certificate/approval.

1.

The enclosures are supplied with drilled and tapped entries. See enclosure drawing

2.

The surface of the machined/threaded flamepaths between cover and body must be

protected from scratches or damage during installation. Any such damage can destroy

the validity of the enclosure.

3.

Before the cover is refitted, the flamepath/threaded joint between cover and body must

be thoroughly wiped clean of dirt, grit or other foreign substances, and then a thin

coating of an approved form of non-setting grease applied to joint/threads. Ensure the

gasket o-ring is free from damage.

4.

Threaded covers must be screwed on to a minimum of 5 full threads of engagement and

then locked in position with the locking screw provided.

5.

All tapped entries must be fitted with an approved flameproof (Exd) device which is

equivalent or superior to the gas group and temperature of the enclosure.

6.

The enclosure should be mounted using the two rear M6 tapped holes.

7.

Do not scratch the glass.

8.

Glanding of cables should be as in Selection of Cable Gland section.

Enclosure with Front Cover Removed