Fire Fighting Enterprises Talentum UV/IR2 Flame Detector User Manual

Page 2

2

•

•

•

•

•

•

•

11

Application for Flame Detectors

Flame detectors are used when detection is required to be:

Unaffected by convection currents, draughts or wind

Tolerant of fumes, vapours, dust and mist

Responsive to a flame more than 25m away

Fast reacting

The detector is capable of detecting the optical radiation emitted by burning material even non-

carbonaceous materials. e.g. Hydrogen

Numerous other potential fire sources can be detected such as

Liquids

Solids

Gases

● Aviation Fuels (kerosene)

● Coal

● Butane

● Ethanol

● Cotton

● Fluorine

● Methylated Spirits

● Grain & Feeds

● Hydrogen

● n-Heptane

● Paper

● Natural Gas

● Paraffin

● Refuse

● Off Gas

● Petrol (gasoline)

● Wood

● Propane

Typical applications examples are:

● Agriculture

● Coal handling plant

● Pharmaceutical

● Aircraft hangars

● Engine rooms

● Power plants

● Atria

● Generator rooms

● Textiles

● Automotive industry

● Metal fabrication

● Transformer stations

- spray booths

● Paper manufacture

● Waste handling

- parts manufacture

● Petrochemical

● Woodworking

Applications and Locations to Avoid:

● ambient temperatures above 55°C

● large IR sources – heaters, burners, flares

● close proximity to RF sources

● obstructions to field of view

● exposure to severe rain and ice

● sunlight falling directly on the detector optics

● large amounts of flickering reflections

● spot lighting directly on the detector optics

Quantities Required and Positioning of Detectors

The number of detectors required and their position depends on:

the anticipated size of the flame

the distance of the flame from the detector

the angle of view of the flame detector

The flame detector is designed to have a class 1 performance as defined in BS EN54-10:2002

on the high sensitivity setting. That is the ability to detect an n-heptane (yellow) fire of 0.1m² or

methylated spirit (clear) fire of 0.25m² at a distance of up to 25m within 30 seconds.

The detector can be set to have to a lower sensitivity setting equivalent to class 3 performance.

Class 3 performance is defined as detecting the same size fires as for class 1 but at a distance

of only 12m.

Functional Testing

When 24Vdc power is applied to the detector

the green supply on indicator LED will

illuminate. The fault relay RL2, if selected

with the DIL switch, will energise and the

contact between terminals 7 and 8 will close.

If 24Vdc is applied to terminals 3 and 4 or

terminal 3 is linked to terminal 1 the detector

will perform a self-test. It does this by

causing internal optical test sources to

simulate the behaviour of flames and the

detector will alarm.

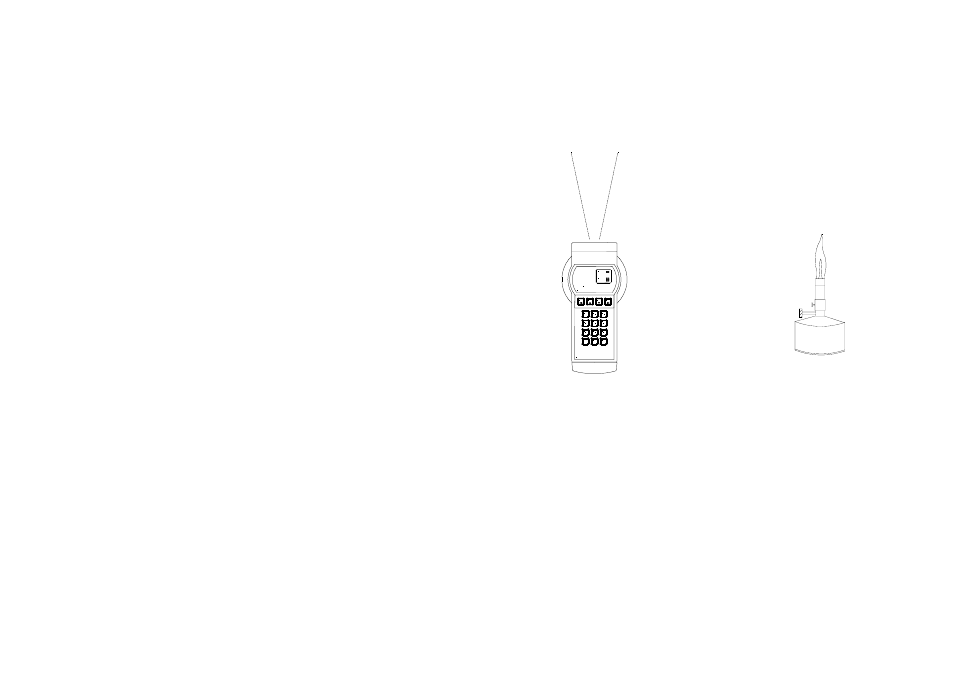

Alternatively a portable flame sensor test unit

is available to generate simulated flame

behaviour and test the detector a few metres

in front of the detector. See Fig 12.

Finally, provided it is safe to do so, carry out

a flame test using a flickering flame source,

such as a portable Bunsen burner.

See Fig 13.

A still non-flickering flame will not produce a

response from the detector.

Fig 12 Portable Flame Detector Test Unit

Fig 13 Portable Bunsen Burner

Service & Repairs

Servicing of the fire protection system should

be carried out by competent persons familiar

with this type of system, or as recommended

by the local regulations in force.

Only the manufacturer or equivalent

authorised body may carry out repairs to the

flame detectors. In practical terms this

means that flame detector may be repaired

only at the manufacturers factory.

*

6912

6913

7

4

WXYZ

0

#

PQRS

8

TUV

9

MNO

5

JKL

6

GHI

F4

F2

F3

F1

1

DEF

2

ABC

3

FLAME SENSOR TEST UNIT

SUPPLY

SIGNAL