FEC DSP1500 (SAN3) User Manual

Page 25

enFORCE

Operation Manual

PAGE 4 - 25

Chapter 4: System Setup and Wiring

4.13 Tool Connections

Tools are connected to the SAN controller using three or four cables. The first cable connects to the

Load Cell Force Transducer preamp. Second is a combination Motor / Resolver Cable. The third

cable connects the position proximity switches for home and advanced position indication. A fourth

cable is for an external brake if ordered. Each cable is separated from the Motor / Resolver cable to

reduce the possibility of high voltage noise interference. In multiple press systems, each cable is

labeled with a corresponding press number and should be connected to the corresponding SAN

Controller and Tool.

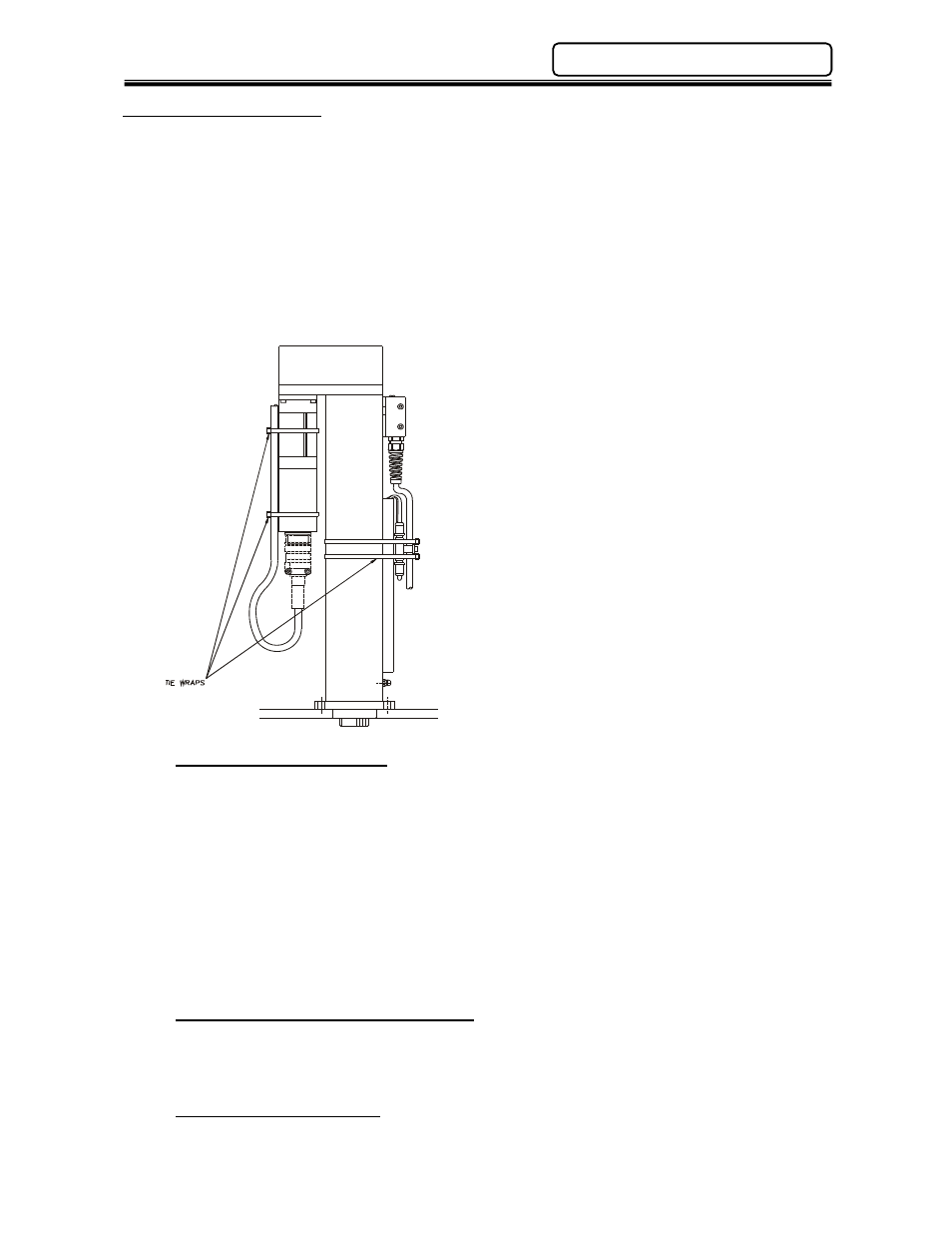

Cables should be secured to the motor similar to the method as shown below. If cable ties are used,

they should be loose enough to allow the cable to move, but yet hold it in place. Cable ties too tight

cause a stress point leading to premature cable failure.

*Recommended Cable Lengths: 75’ or less.

*Maximum

Cable

Lengths:

100’ (must be free

from Electrical Noise)

MOTOR / RESOLVER CABLE

RM1, 2 & 3 MOTOR (FIELD):

FEC

P/N:

FEB-1251

RM4

MOTOR

(FIELD):

FEC

P/N:

FEB-1605

RM1, 2, 3 & 4 MOTOR (EXTENSION):

FEC

P/N:

FEB-1283

Nominal OD = .505”

Min. Bend Radius = 6.0“

RM5 MOTOR (MOTOR FIELD):

FEC P/N: FEB-1604

RM5

MOTOR

(MOTOR

EXTENSION):

FEC

P/N:

FEB-1606

Nominal OD = .415” (x2)

Min. Bend Radius for group = 10.0“

RM5

MOTOR

(RESOLVER

FIELD):

FEC P/N: FEB-1603

RM5

MOTOR

(RESOLVER

EXTENSION):

FEC

P/N:

FEB-1283

Nominal OD = .535”

Min. Bend Radius = 6.0“

LOAD TRANSDUCER (PRE-AMP) CABLE

RM1, 2, 3, 4 & 5 MOTOR (FIELD):

FEC

P/N:

FEB-1173

RM1, 2, 3, 4 & 5 MOTOR (EXTENSION):

FEC

P/N:

FEB-1284

Nominal OD = .405”

Min. Bend Radius = 4.0“

POSITION SENSOR CABLE:

Brad Harrison female 4 pin Micro style cable or equivalent

(See Appendix A)