Welch Vacuum 2028 Self-Cleaning Dry Vacuum System User Manual

Page 20

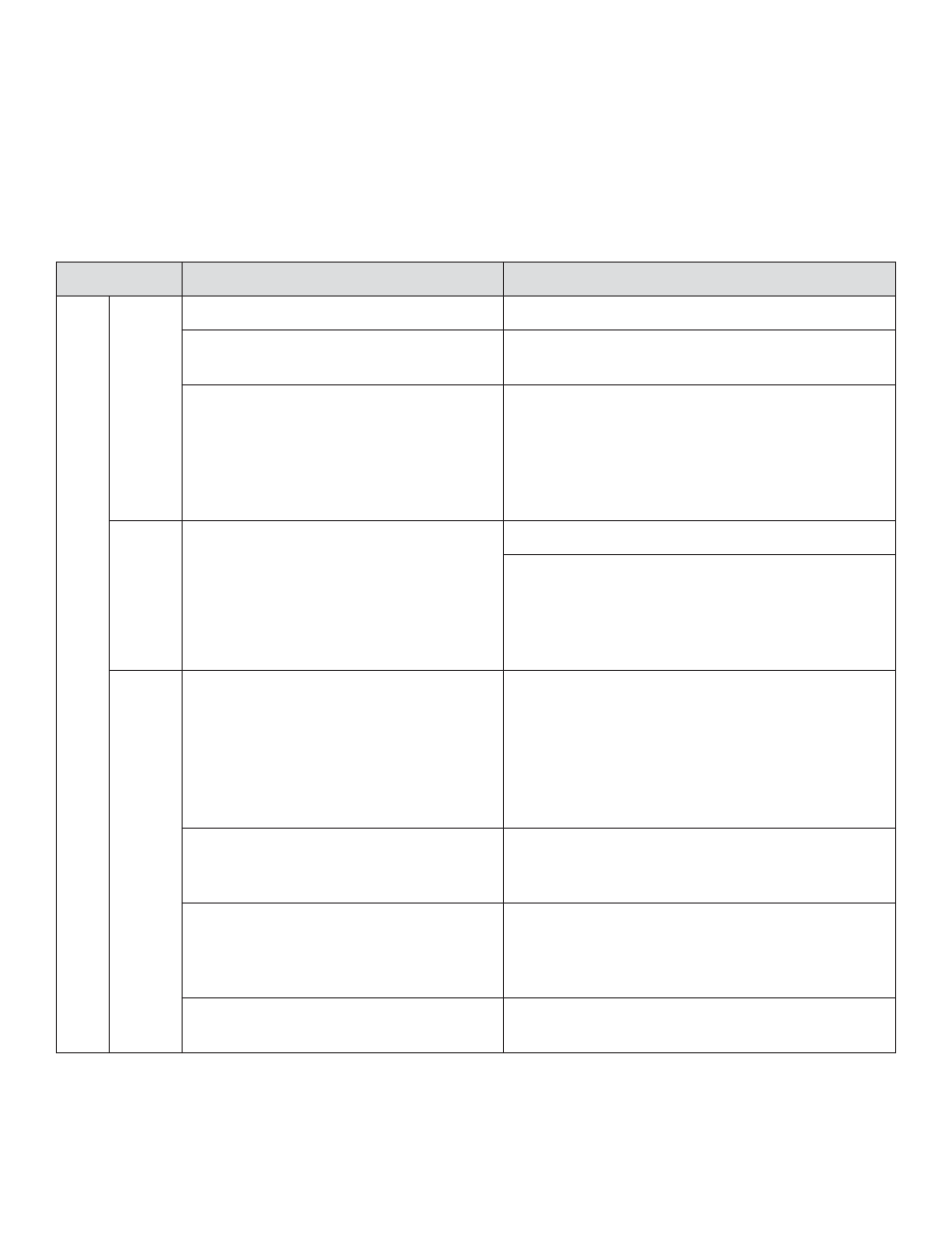

Section 6: TROUBLESHOOTING

6.10 Vacuum Problems

Leakage, contamination and unusual out gassing are the general causes of problems associated with

poor vacuum. To operate at maximum effi ciency a system must be thoroughly clean. If the system is

completely clean and free from leaks, and unwarrantable vacuum problems still exist, the pump should

be checked. A simple criterion for checking the condition of the pump is the determination of its maximum

vacuum capability. This can be accomplished by blocking off the intake and reading the vacuum level on

the gauge (See Section 3.30).

Problem

Possible Cause

Solution

Mechanical Failures

Pump not working

Power off

•

Check all power connections

•

Pump under Vacuum

•

Disconnect pump from system.

•

Open vacuum control valve and Gas ballast.

Self Diagnostic Test

•

Do nothing - The pump is running a 30sec. Self

•

diagnostic test to ensure all components are

working correctly.

If problem persists, contact Welch

Technical Support*.

Pump stalled

Pump under vacuum

•

Note:

Pump Cannot Start Under Vacuum

Open vacuum control valve and gas ballast.

•

Turn-off and UNPLUG PUMP, remove top

•

housing and turn fan a few times. Replace

cover and turn on, if problem still continues

contact Welch Technical Support*. Turn pump

off, disconnect from application, restart pump

Display shows unreliable measurements

Check vacuum pressure of 2027xx

•

with external vacuum gauge, attached

to pump inlet fi tting.

If external vacuum gauge pressure is different

•

than unit’s display by more than 5 Torr, problem

is with one of three electronic parts (electronic

problems):

- Vaccum pressure display

- Pressure pickup

- Electronic board

Loose or not completely inserted wire

•

or connector

All electronic connections on electronic board

•

and vacuum display should be rechecked to

see that there is no

Multi wired pickup ribbon connection

•

at pressure pickup may have loose/

broken one of the four wires (usually

one of outside wires).

New pickup should be installed or repaired by

•

re-soldering loose wire to pressure pickup.

Electronic board could have corrupted

•

software or calibration

Faulty board should be returned to the factory

•

to exchange it for new one

20