Welch Vacuum 2028 Self-Cleaning Dry Vacuum System User Manual

Page 16

16

3.40 Vacuum Level Regulation

Vacuum level regulation is accomplished with an adjustable bleed valve. The adjustable bleed valve

allows close control of pressure in your apparatus. Pressure may be set between roughly atmospheric

pressure and the maximum obtainable vacuum (2 torr, 2.7mbar, 29.8 in Hg).

3.50 Gas Ballast Valve (Models 2025, 2026 & 2027 only)

Failure of a diaphragm pump using fl uorinated plastics commonly comes from the buildup of liquids or

solid residue over time on the diaphragm or internal valves. Any particulates, water or condensed vapor

that may have been ingested into the diaphragm pump, which is the heart of the Self-Cleaning Dry

Vacuum System, is purged when the system is turned off. The self-cleaning purge automatically turns on

for approximately 2 minutes upon turning off the pump. The digital display will count down in seconds the

time left in the purge cycle. During the last 10 seconds of the purge cycle the pump will shut off allowing

the unit to vent to atmospheric pressure.

3.60 Rapid Response Vacuum Adjustment

Foaming or bumping in a rotary evaporator can be caused by excessively high vacuum levels. Your

Self-Cleaning Dry Vacuum system enables fast response to foaming and bumping. Depending upon your

Model, a toggle switch or button can instantly adjust vacuum levels to approximately 10 torr higher by

incrementally changing the gas ballast valve.

Models 2025, 2026 & 2027 have a toggle Gas Ballast Valve to enable Rapid Response Vacuum

Adjustment. By moving the Gas Ballast Valve toggle switch to its upward position, the valve is opened.

This open valve allows air to enter the pump’s second stage, reducing the vacuum level. This reduction

will be most effective at eliminating bumping and foaming in the low Torr range; vacuum will typically

increase 10 to 15 Torr. Higher Torr evaporations (e.g. methylene chloride) may also require adjustment of

the vacuum level using in the regulator. Operation with the gas valve open will also reduce condensation

in the pump’s second stage, increasing effi ciencyand extending service life.

Prolonged operation of the pump with the Gas Ballast Valve open is not injurious to the pump. As your

evaporation progresses to the point where bumping or foaming is no longer a potential problem, close the

gas ballast valve to enable maximum vacuum.

Model 2028 provides Rapid Response Vacuum Adjustment by use of the Anti-Bumping / Foaming

button. Pushing this button increases your vacuum set point by 10 Torr. The variable control valve opens

incrementally to admit air to both stages of the pump and the vacuum level is now controlled 10 Torr

higher than the previous setting. Pushing the Anti-Bumping / Foaming button a second time will raise the

set point another 10 Torr.

Prolonged operation of the pump at any vacuum setting is not injurious to the pump. As your evaporation

progresses to the point where bumping or foaming is no longer a potential problem, you can increase

vacuum by lowering the set point in “Auto” mode or switching to “Manual” mode and pushing the

Maximum Vacuum button

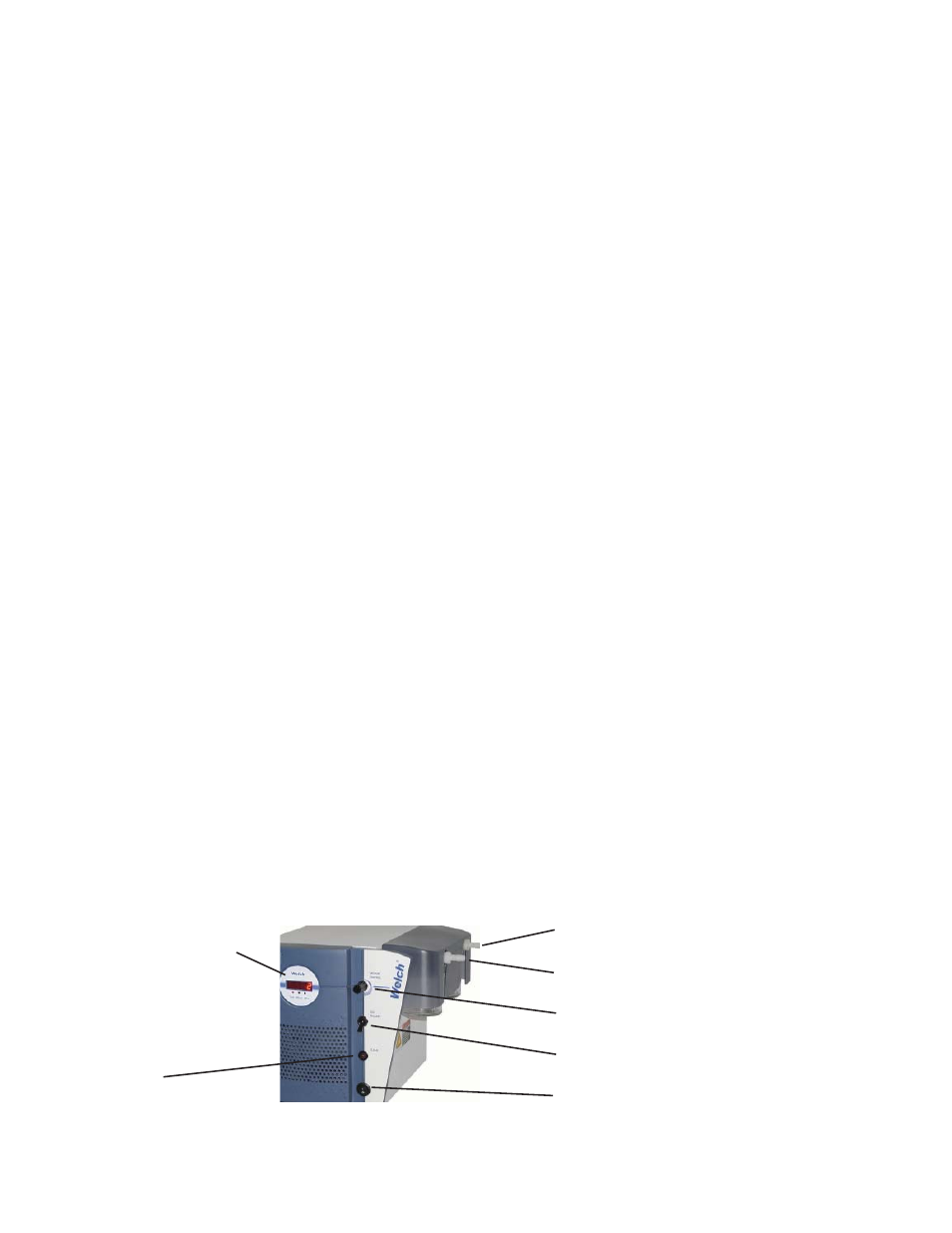

Separator

Outlet

Vacuum

Gauge

Inlet

Vacuum

Level

Regulator

Gas

Ballast

Valve

Clean

Power

Switch

(Model 2027 shown. Models 2025 and 2026 come with a dial vacuum gauge)