Teledyne LXT-280 User Manual

Page 49

Dissolved Oxygen Transmitter

Maintenance

Teledyne Analytical Instruments

39

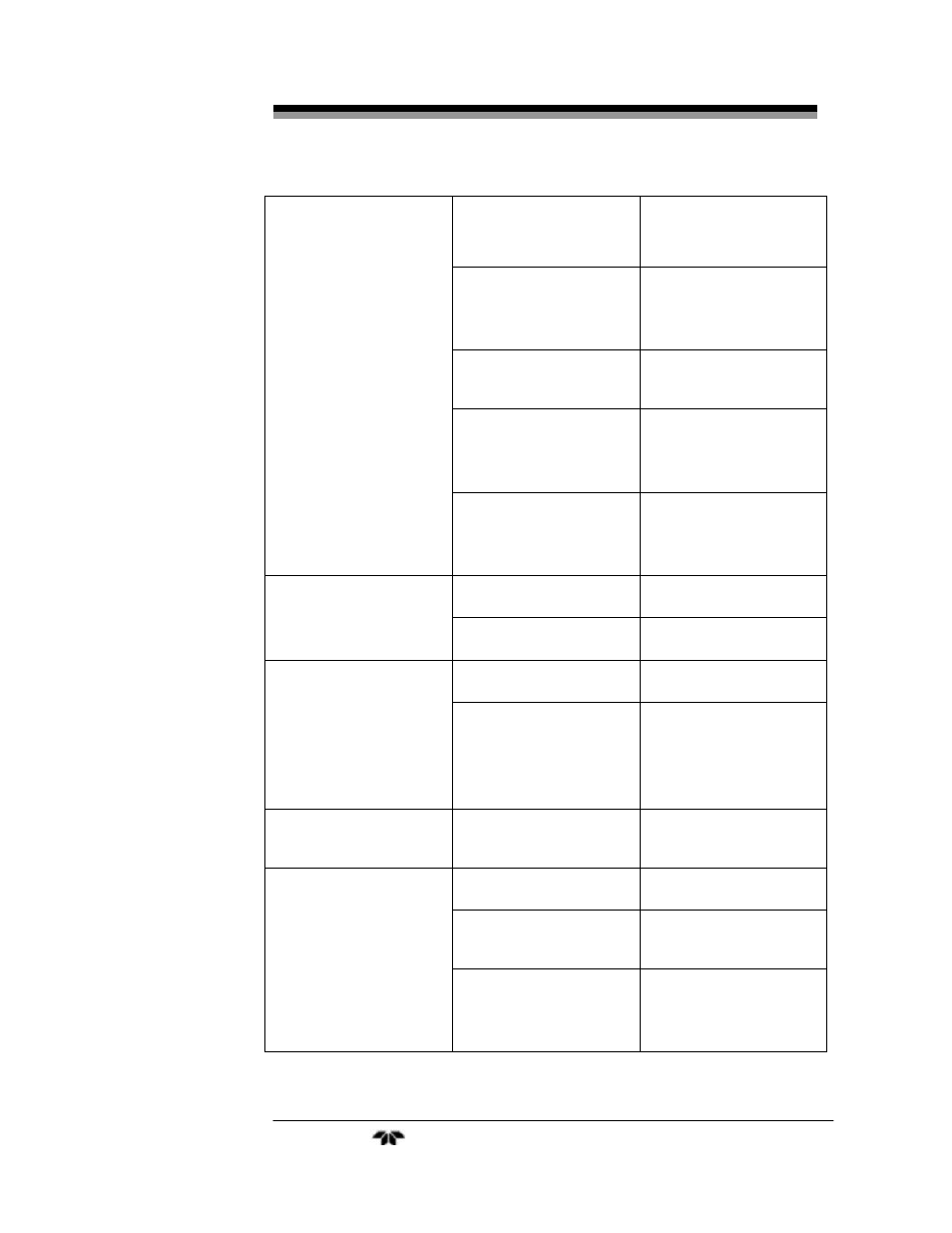

Broken membrane

Replace the electrode

cartridge.

Process flow is not

adequate across the

electrode membrane

Locate the sensor within an

adequate flow or create

agitation within the

process.

Sensor is located too close

to the oxygen injection

point.

Locate the sensor further

from the oxygen injection

point.

Signal conditioner not

properly engaged in the

rear of the sensor body.

Verify that the signal

generator is properly

engaged in the rear of the

sensor body.

Instrument has been

improperly calibrated. May

have been calibrated with

no slope (infinite gain)

Verify instrument

calibration electronically,

then recalibrate per

Section 4.

Membrane is coated

Clean the membrane. See

Sensor manual.

Slow Response

Protective Boot was left on

the front of the sensor.

Carefully remove the

protective boot.

Broken membrane

Replace electrode

cartridge.

No Span

Temperature compensator

(TC) is open.

Verify that the sensor is

properly connected

including the TC

connections. Check for a

damaged TC in the sensor

body. Replace if damaged.

Reading drifts upscale or

zero calibration reads

upscale

Broken membrane

Replace the electrode

cartridge.

Broken membrane

Replace the electrode

cartridge.

Coated membrane

Clean the membrane. See

Sensor manual. Verify

instrument calibration.

Short span or the electrode

does not respond to a

second calibration point.

Electrode cartridge is not

fully engaged in the sensor

body

Check electrode cartridge

to see that it is fully

engaged in sensor body