SPP Pumps Auto Prime Hydraulic Submersibles - S4VHL User Manual

Page 8

Manual No/Rev

W79-003E / 4

Operators Instructions for

HYDRAFLOW S4VHL Hydraulic Submersible Pump

Our policy is one of continuous improvement and we reserve the right to alter specifications at any time

Page 8 of 12

remove bearings from shaft. Do NOT use heat

to remove bearing from shaft.

6.4 Pump Assembly:

Assembly is performed in the reverse order

of disassembly with care taken to be sure

that:

6.4.1

After shaft and bearing assembly are installed

in housing, snap-ring (#11) is secured and shaft

rotates freely.

6.4.2

Shaft seal (#25) is kept extremely clean

at all times. Be careful not to scratch

sealing surfaces. Install ceramic seal

seat into rubber boot carefully to be sure

rubber is seated properly. Install seal

cartridge onto shaft carefully using oil to

lubricate the carbon face and the rubber

bellows. Install the impeller slowly to be

sure it contacts the seal evenly and

applies pressure properly to seat the seal

assembly. Be sure carbon face of

rotating cartridge contacts smooth side of

stationary ceramic seat.

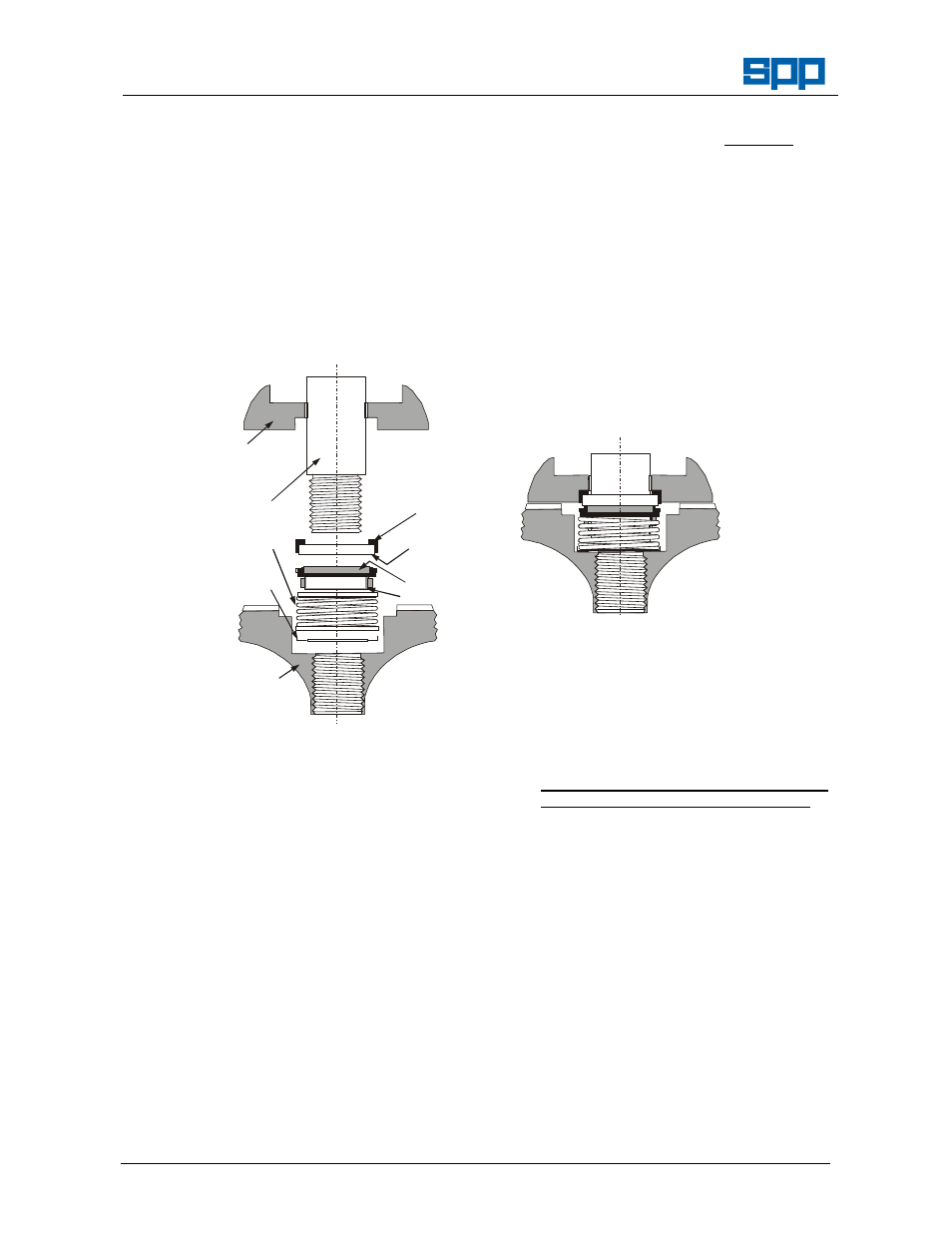

Bearing

Housing

Shaft

Spring

Retainer

Impeller

Rubber Bellows

Carbon Face

Polished

Ceramic Face

Rubber cap

Mechanical Seal Arrangement

Exploded

Mechanical Seal Arrangement

Assembled

6.4.3

"O" ring are properly installed in grooves.

6.4.4

Impeller locking screw (#30) is secured

properly to XX NM torque (40 ft. lbs.)(58

joules).

6.4.5

Drive assembly rotates freely before

installing into volute. The hydraulic motor

and seal will cause some drag. Be sure

hose ports are open on the motor so as not

to get hydraulic binding.

6.4.6

Anti-seize lubricant should be used on all

fasteners when re-assembling pump.

6.4.7

Bearing housing is refilled with oil to the

bottom of the fill plug (#15) spill point.

6.4.8

Before submersing pump, test run on dry

land.

Check for proper rotation of impeller.

(Counter-clockwise looking into volute inlet)

The pump will run backwards and pump

water though at noticeably lower volumes.

6.5 Pump Hose Connection:

NOTE – When the pump hose connections have

been disconnected from the hydraulic motor

it is IMPORTANT to ensure that they are

refitted correctly. Refer to the Figure for the

correct position of each hose connection.