SPP Pumps Auto Prime Hydraulic Submersibles - S3T User Manual

Page 7

Operators Instructions for

HYDRAFLOW S3T Hydraulic Submersible Pump

Manual No/Rev

W79-007E / 4

Our policy is one of continuous improvement and we reserve the right to alter specifications at any time

Page 7 of 12

150SSU @ 38°C (100°F) or equivalent

specification.

Note: When using vegetable (Rape Seed) based

bio-degradable oil it is important to check

the condition of the oil frequently as it tends

to breakdown more quickly than the more

expensive

mineral

or

synthetic

bio-

degradable oils.

NOTE – DO NOT MIX OILS

Look especially for a darkening in colour as

an

indicator

of

reduced

lubrication

performance or contamination and arrange

to drain the system, clean the tank and

replace with new oil.

6.1.2 Lubricating Oil:

Use clean Bio-degradable Hydraulic 46 Oil

or 20W Hydraulic Oil or Mobil 10W30

Synthetic Oil.

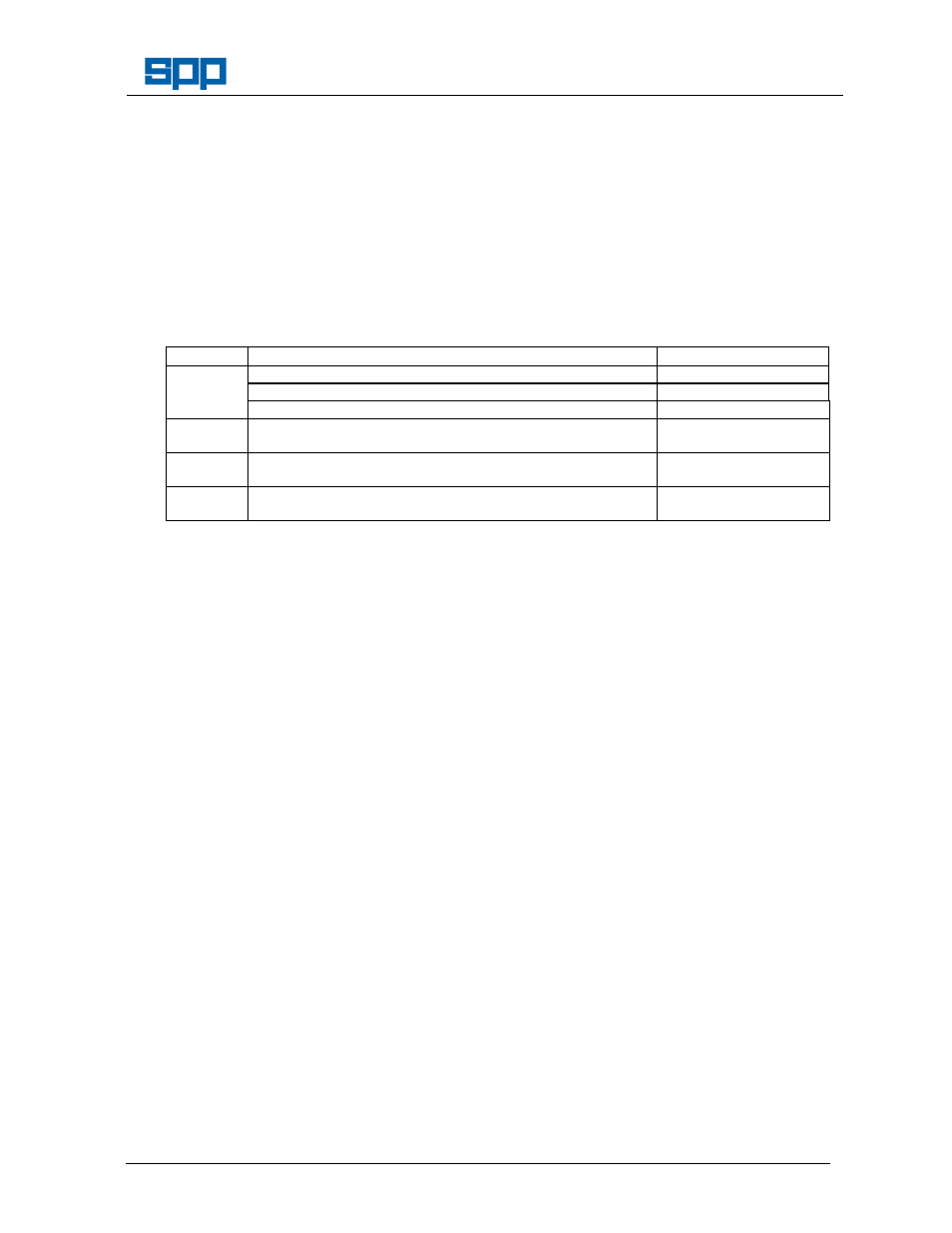

6.2 Maintenance Chart

Period

Maintenance

Items Required

Daily

Check hydraulic hoses for damage and replace as required.

Spare hydraulic hoses

Check Diesel fuel level, top-up as required.

Diesel Fuel

Check Hydraulic oil level, top-up as required.

Hydraulic Oil

Weekly

Check the level and condition of the oil in the pump seal

chamber and top up if necessary.

Hydraulic Oil

(approx 1 oz)

500 hours Replace hydraulic oil filter element. (10 micron filter)

Change the oil in the pump seal chamber

Oil Filter Element.

Hydraulic Oil (app. 1 oz)

1000 hours Drain hydraulic oil, clean the reservoir tank and replace with

new oil.

Hydraulic Oil (100 l)

Cleaning Solvent

6.3 General

The only routine maintenance required

under normal use is to check oil in seal

cavity in top cover (#11). This oil is to be

20W hydraulic oil (approx. 1 oz.). Change

oil every 500 hours of operation. If no oil is

present or oil is emulsified, shaft seal may

need replacement.

Further maintenance may be required if:

(a) Pump discharge volume is inadequate.

(b) Oil leakage from pump is present.

6.4 Pump Disassembly:

6.4.1

Remove six 3/8" bolts (#12) From top

cover.

6.4.2

Remove top cover and motor assembly

from volute (#3).

6.4.3

Check condition of "O" ring (#10) and

replace if necessary.

6.4.4

Check for debris in the volute.

6.4.5

Check wear ring (#4). Replace if wear is

excessive.

6.4.6

Hold impeller (#7) securely and remove

socket head retaining screw (#5) and cone

washer(#6) from impeller end.

6.4.7

Using hex key wrench, or hex key socket

with impact wrench, unscrew impeller (#7)

(right hand threads).

6.4.8

Check impeller for wear and replace if

necessary.

6.4.9

Remove 2 bolts (#15) from handle (#16)

and remove.

6.4.10

Remove seal spring and washer.

6.4.11

Remove 2 motor mounting bolts (#21) from

top cover and carefully remove motor(#22).

6.4.12

Inspect "O" ring (#13) and replace if

necessary.

6.4.13

Check top cover for wear and replace if

wear is extreme.

6.4.14

Do not disassemble hydraulic motor (#22).

If hydraulic motor needs service, it should

be performed by a qualified Sterling Fluid

Systems Service Engineer or replaced.

6.5 Pump Reassembly:

6.5.1.

Fasten motor to top cover making sure the

"O" ring (#13) is in place.

6.5.2.

Install new shaft seal (#9) keeping the parts

extremely clean and using clean grease to

aid installation.