Pump maintenance chart, Maintenance instructions – SPP Pumps Auto Prime Medium Head Open Set - AL Range User Manual

Page 8

Manual No/Rev

W72-025E / 3

Operators Instructions for

AL100 & 150 Diesel Driven Centrifugal Pumps

Our policy is one of continuous improvement and we reserve the right to alter specifications at any time

Page 8 of 12

6. PUMP MAINTENANCE CHART

For engine maintenance periods refer to the engine operators handbook supplied with this manual.

PERIOD

TASK

Daily

Visually check for leaks and vibrations

Check for vibration.

Check the mechanical seal oil level and top up as required.

Drain any water from coalescer, check oil level and top up as required

Weekly or

100 hrs

Check all fastener security.

Check the condition of the lifter bracket/frame and check the security of attachment to

the unit.

Check tension of vacuum pump drive belt.

Monthly or

500 hrs

Change coalescer sump oil

Clean coalescer sump oil filter mesh

Remove front cover and check pump internals for wear

Check valve gear - clean or renew standard filter element. Check high capacity filter

element.

Grease the pump bearings

6 monthly

or 1500 hrs

Check reflux ball is sealing on its seat.

Check and if necessary renew vacuum pump drive belt.

Dismantle and clean valve gear, tank, connecting pipes and priming tank.

Change mechanical seal oil.

Annually or

6000 hrs

Check vacuum pump blade condition

Check bearing condition

Renew coalescer filter mesh

The above schedule is given for guidance but site operating conditions may override the suggested

maintenance intervals

.

7. MAINTENANCE INSTRUCTIONS

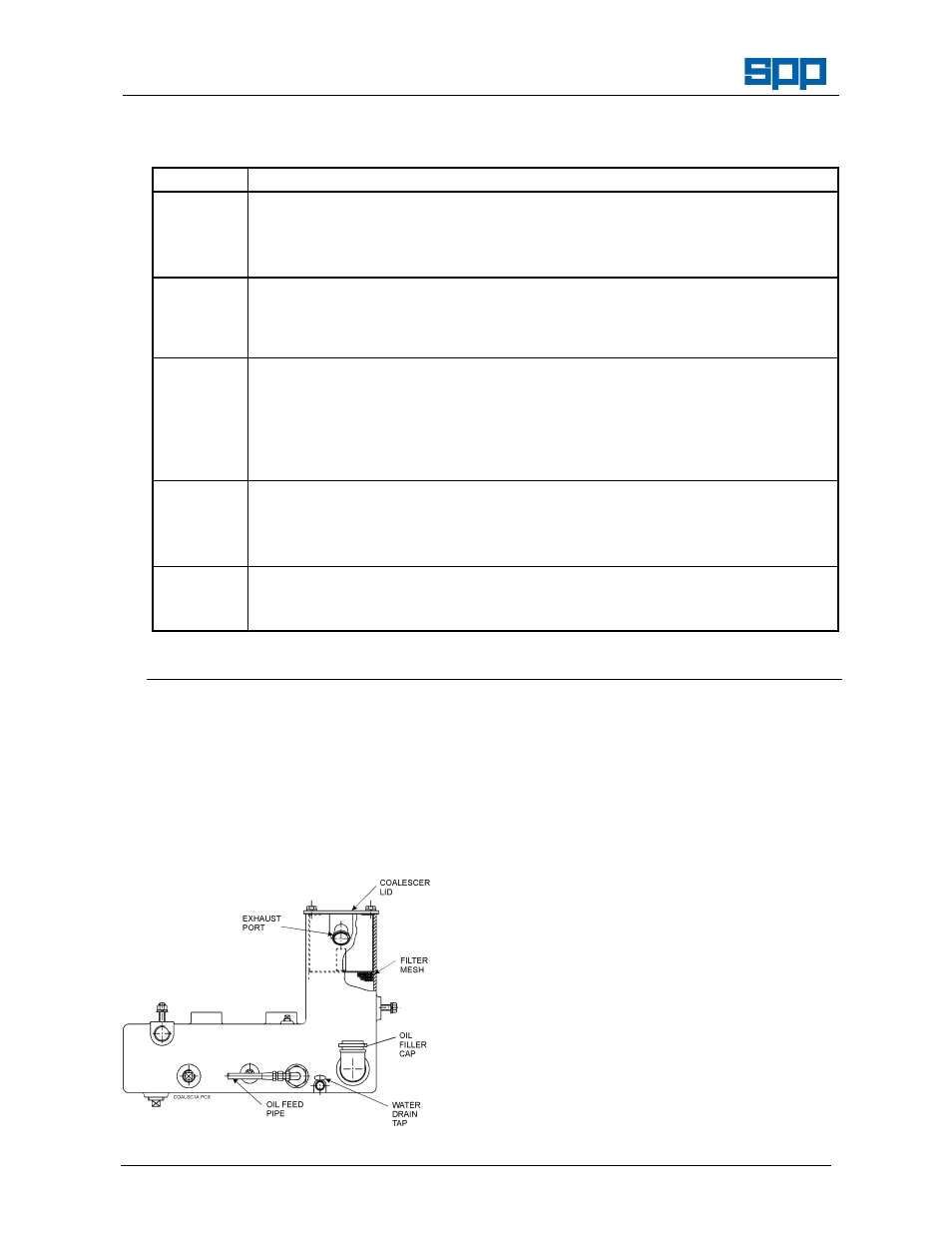

7.1 Coalescer Maintenance

1. Check the oil level in the coalescer tank and

drain any water daily. The top of the oil

should be level with the underside of the

filler cap. Water is removed by means of

the drain tap fitted to the side of the

coalescer sump.

Coalescer detail

2. The filter mesh is accessed by removing the

coalescer lid and must be cleaned regularly

by washing in petrol or a similar spirit.

When refitting ensure filter mesh is below

exhaust port. The oil feed pipe should be

cleaned in a similar manner and blown

through with an air line.

7.2 Mechanical Seal Oil Reservoir

Maintain the oil level between the maximum

and minimum levels marked on the dipstick.

7.3 Drive Belt Adjustment

1. Remove the drive belt guard.

2. Slacken the nuts that secure the vacuum

pump, move the vacuum pump to give the

required belt tension and tighten the nuts.

Check the tension again and readjust, if

necessary.

3. V Belt tension is correct when the deflection

is 4mm with a force of 1.5kg applied at the

centre of top run.