2 introduction, 3 installation – SPP Pumps Split Case Pumps User Manual

Page 5

Pump Installation Guide

Manual No/Rev

W00-002E / 4

Our policy is one of continuous improvement and we reserve the right to alter specifications without giving notice.

Page 5 of 12

2 Introduction

This manual specifies SPP Pumps Limited

requirements for the installation of SPP

horizontal and vertical split case and end

suction pumpsets.

SPP Pumps Limited requires that this

document is given to all contractors with

responsibility for site preparation, electrical

supply and connection, pump installation

and pipework etc.

On completion of all stages that apply, a

signature should be obtained from the

contractor's

representative

confirming

compliance with SPP requirements.

If SPP Pumps Limited Service Department

have been requested to perform initial

testing,

these

documents

MUST

be

submitted signed before commissioning can

be undertaken.

This

guide

covers

the

installation,

connection and initial testing of a SPP

Pumps pumpset, comprising baseplate with

electric

motor,

flexible

coupling

and

centrifugal pump or close coupled pump

unit.

All other items required for the installation

must be provided by the customer or the

contractors responsible for the installation.

2.1

Review of Equipment Received

On receipt of the pumpset it is important to

check for any damage or loss that may

have occurred in transit. Any damage or

missing items should be referred in the first

instance

to

the

haulage

contractor

responsible.

3 Installation

3.1

Pump Location

The pump should be installed as near to the

liquid source as possible, with the shortest

and most direct suction pipe practical.

Allow sufficient access for inspection and

maintenance with enough headroom for an

overhead crane or hoist of sufficient

capacity to lift the heaviest item of

equipment.

Adequate ventilation is required for cooling

purposes, inlet and outlet apertures,

suitably sized and positioned to prevent air

re-circulation, must be provided in the pump

house structure.

3.2

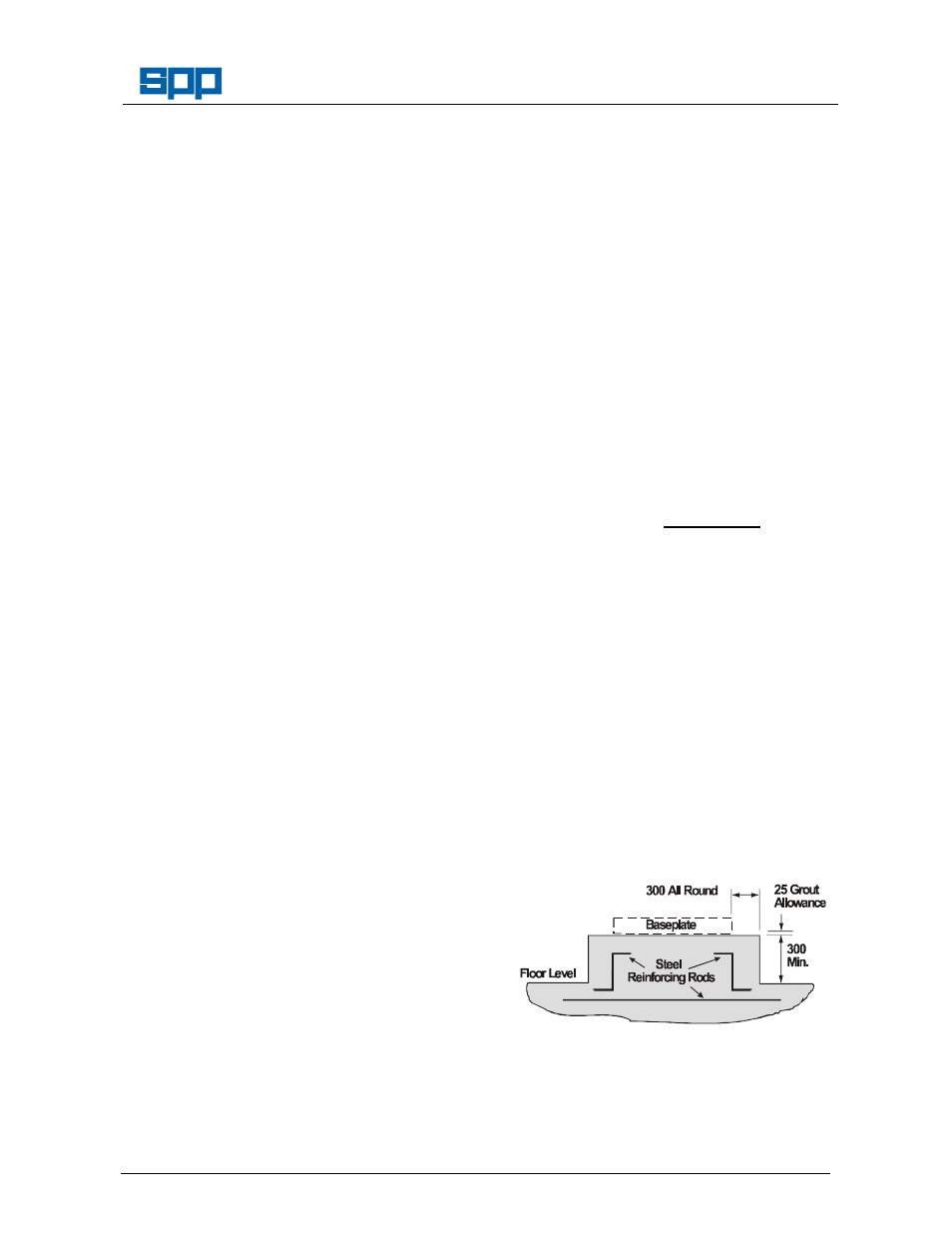

Foundations

A foundation plinth should be constructed to

support each pumpset on a floor area free

from expansion joints. These foundation

plinths should be sufficiently substantial to

absorb vibrations and rigid enough to avoid

any twisting or misalignment.

As a rough guide, they should be at least

300mm wider than the pumpset on all sides

and weigh between 1 and 1.5 times the

weight of the pumpset. Plinths for pumps

are recommended to have a minimum

height of 300mm but height should be

sufficient to achieve the necessary weight

and to accommodate the pockets for fixing

bolts.

Foundation height may be calculated thus:

Height (m) =

W

2400 x B x L

where:

W (kg)

= total weight of pumpset

2400 (kg/m

3

) = concrete density

B (m)

= foundation width

L (m)

= foundation length

Use a suitable concrete mixture by volume

is 1:2:3 (Cement : Sand : Aggregate) with a

maximum 100mm slump, and a 28 day

compressive strength of 27,000 N/mm

2

.

Foundation concrete should be poured

without interruption to within 25mm of the

finished height.

The foundation should be reinforced with

layers of 150mm square No.8 gauge steel

wire fabric, or equivalent, horizontally

placed 150mm apart.

The top surface should be well scored and

grooved before the concrete sets to provide

a bonding surface for the grout. The

foundation should be allowed to cure for

several days before installation of the

baseplate.