5 commissioning, 6 grouting – SPP Pumps Split Case Pumps User Manual

Page 10

Manual No/Rev

W00-002E / 4

Pump Installation Guide

Our policy is one of continuous improvement and we reserve the right to alter specifications without giving notice.

Page 10 of 12

Install the electric motor starter panel in a

convenient position for use and wire up to

mains supply and to the electric motor.

Earth bonding connections are provided on

all base frames and must be connected to a

suitable earth point.

4.2

Seal Flush and Cooling Systems

Where applicable, if a separate supply for

the pump seal is to be used, connect the

feed pipes.

4.3 Waste and Drain Lines

Waste water lines should be run from all

ancillary connections such as gland drains

or tundish etc. Where applicable, these are

shown on the General Arrangement

Drawing provided.

When installed under positive suction head

conditions, pumps should be provided with

an air release valve on the top of the pump

casing to provide a means of exhausting

trapped air.

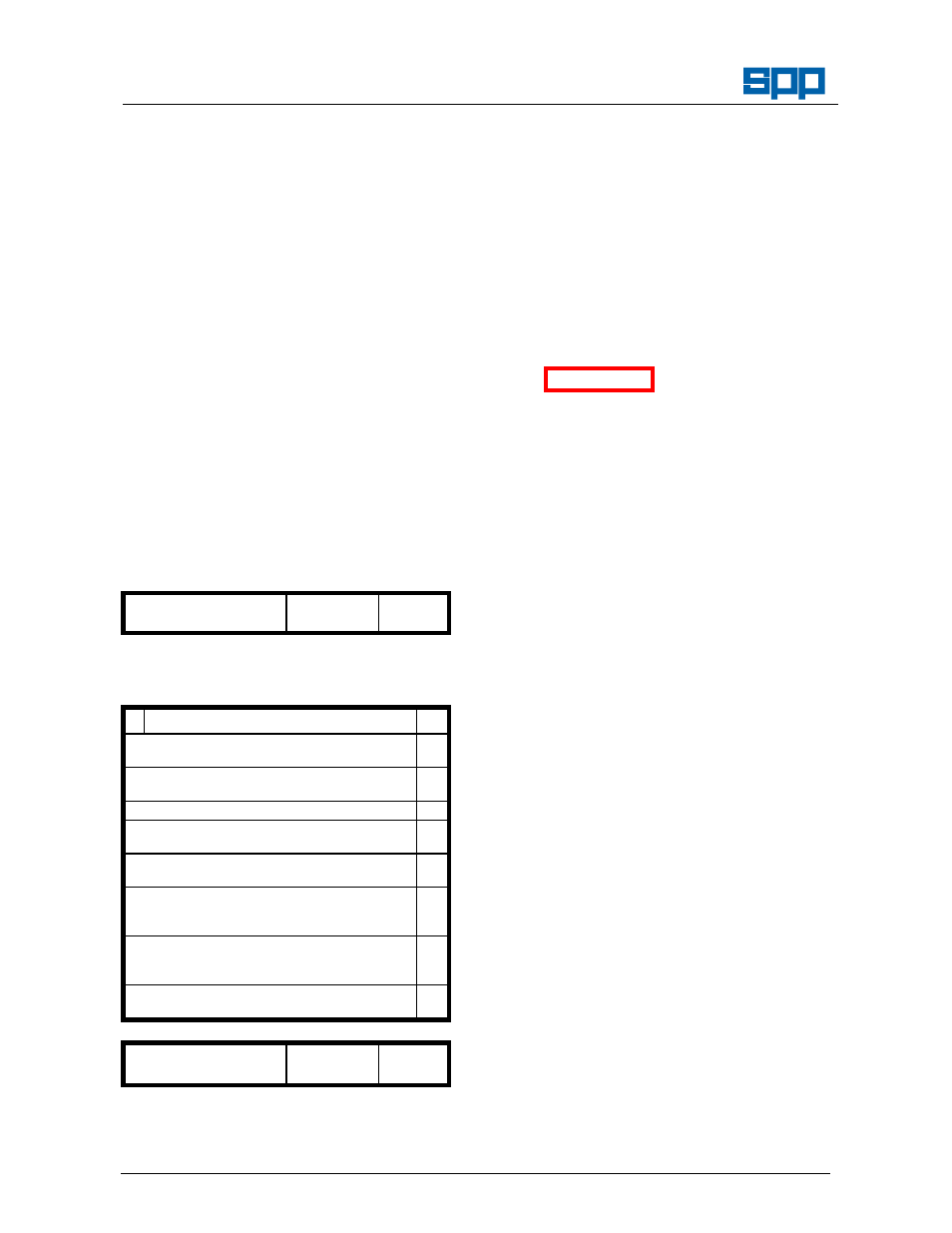

Services connected to

specification.

Signed

Date

5 Commissioning

5.1

Pre-commissioning Checks

1

Installation:

ᒕ

ᒕ

ᒕ

ᒕ

a

Mounting plinths comply with instructions for

size, construction and location.

b

Steel packers position the base frame 25 mm

above the top surface of the plinth.

c The pump shaft is horizontal (or vertical).

d

The fixing bolts are grouted as instructed and

tightened to the required torque.

e

The shaft alignment has been checked and

set to within the stated tolerances.

f

Suction and delivery pipework is adequately

supported and NEGLIGIBLE forces are

transmitted to the pump casing.

2

Where applicable, all drain, minimum flow,

and test pipe lines are fitted, together with

valves gauges and flow meters.

3

Sufficient water supply is available for the

commissioning proof run.

Pre - Commissioning

Check List Completed

Signed

Date

If SPP Pumps Limited Service Department

is contracted to carry out the initial test run,

the check-list shows items to be completed

before the engineer arrives. It is SPP

Pumps Limited policy that service engineers

will give as much assistance as possible to

the customer in solving site problems.

However, if due to incomplete installation or

failure of equipment not supplied by SPP

Pumps Limited, further visits are required to

complete commissioning then, additional

charge will be made.

5.2

Initial Test Run

It is recommended that the initial test run is

done

by

an

SPP

Pumps

Limited

commissioning engineer.

ATTENTION

Refer to the pump

instruction manual for instructions for

commissioning pumpsets.

6 Grouting

After successful testing, grouting is required

to compensate for uneven foundations,

distribute the weight of the pumpset,

prevent movement and reduce vibration.

Use only an approved high-strength grout,

prepared and poured in accordance with the

manufacturer's instructions.

Build any formwork required to contain the

grout. If an epoxy grout is to be utilised

then the foundation surface should remain

dry. For other types of grout, soak the top

of the concrete foundation thoroughly with

water until absorption stops then, remove

any excess.

Fit temporary formwork (shuttering) to the

preferred height around the baseplate to

prevent grout running out when poured. Fill

the space inside the baseframe level with

top of the channels or to the level of the top

plate with grout ensuring that there are no

air pockets. DO NOT use vibration

techniques to aid this procedure. Dress

to a smooth finish and allow the grout to

harden.

After the grout has thoroughly hardened

remove the temporary shuttering, check the

foundation bolts and re-tighten if necessary.

Re-check the shaft alignment and adjust

if necessary. The pump is now ready for

normal use.

Approximately 14 days after the grout has

been poured or when it has thoroughly

dried, apply an oil based paint to the

exposed faces of the grout to prevent air

and moisture from coming into contact.