Installation, Important – Poweramp AP SERIES AIR POWERED 4.2009 User Manual

Page 15

13

4111-0009 — Oct 2007

Jan 2009

INSTALLATION

DO NOT use the maintenance prop to support the

raised platform until the maintenance prop has

been properly shimmed and welded. The shims

must be welded to each other, the leveler frame,

and to the front pit curb steel. Failure to do this

may result in serious personal injury or death.

Two people are required to engage the

maintenance prop: one person to operate the lifting

device, the other person to engage the

maintenance prop.

12.With the leveler square in the pit and flush with

the surrounding dock, remove the

banding on the lip of the leveler.

13. Connect the blower motor to the temporary

power supply.

14. Slowly raise the platform. Check for binding as

platform is being raised.

15. If binding occurs, lower the platform. Reposition

leveler and/or add or remove shims as

necessary. Slowly raise platform again. If platform

still binds, contact Poweramp Technical Services

for further instructions.

16. All AP models - Once leveler is flush, square and

does not bind:

a. Install shims under maintenance prop (C)

where prop attaches to leveler frame. Make

sure prop is solidly shimmed.

b. Using the leveler’s blower motor, raise the

dock to the fully open position.

c.Raise maintenance prop to the service

(upright) position and lock prop in this

position using an OSHA approved locking

device.

17. Disconnect power supply from motor.

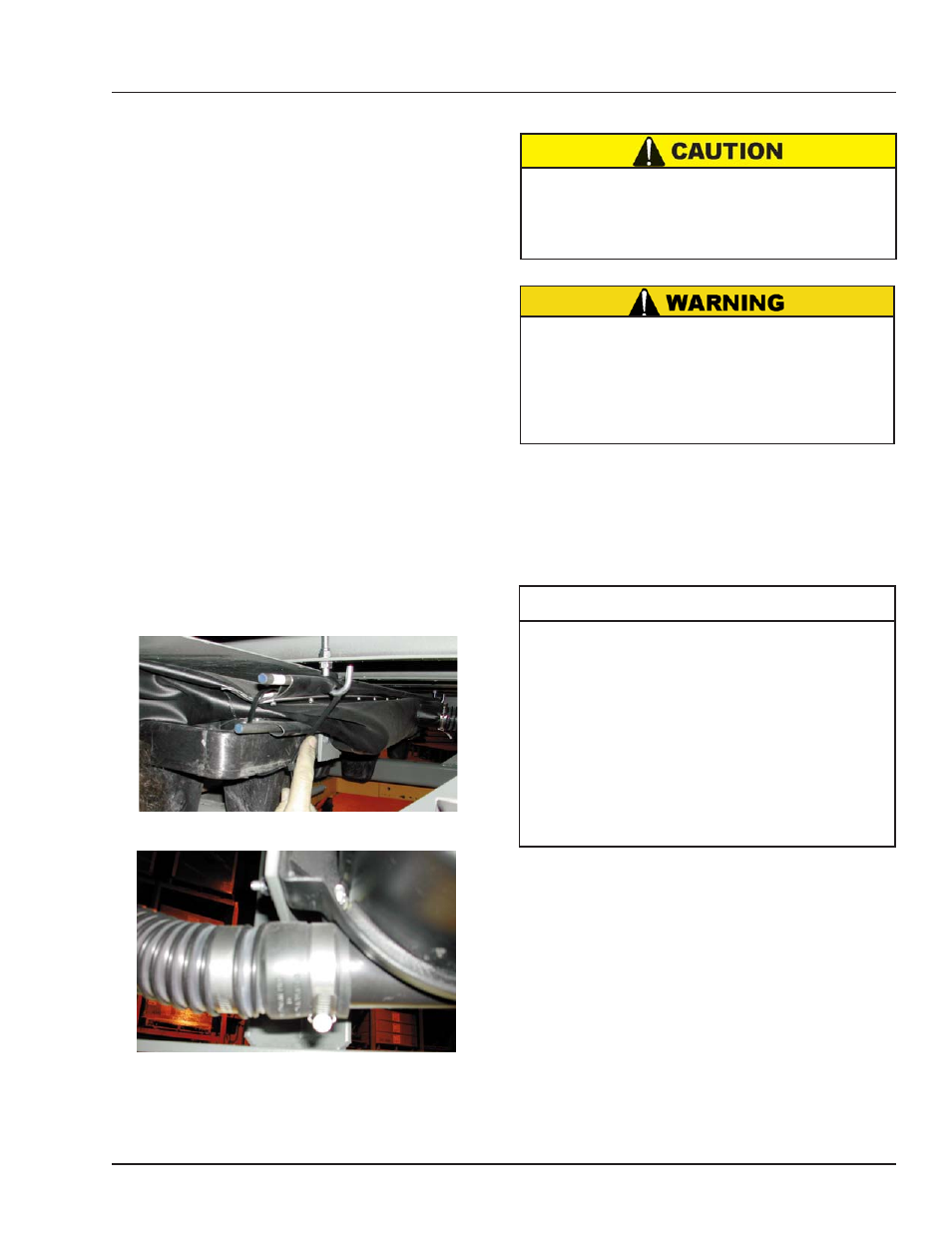

15. Remove air bag and pallet support from the

leveler by disconnecting air bag positioning rods

from hooks on the underside of platform.(figure

1) and removing the band clamp from the motor

coupler. (figure 2)

16. Remove or protect the blower motor from weld

sparks and splatter.

Proceed to step 17.

figure 1

figure 2

IMPORTANT

DO NOT weld before disconnecting all electrical

components.

DO NOT weld before removing air bag, air bag

support pallet and hoses from leveler.

Protect or remove the blower motor before welding.

Failure to follow these instructions may result

damage to these components from stray sparks

and weld splatter.