Installation – Poweramp EH SERIES HYDRAULIC User Manual

Page 19

17

4111-0004 —November 2003

Rev “B” February 2011

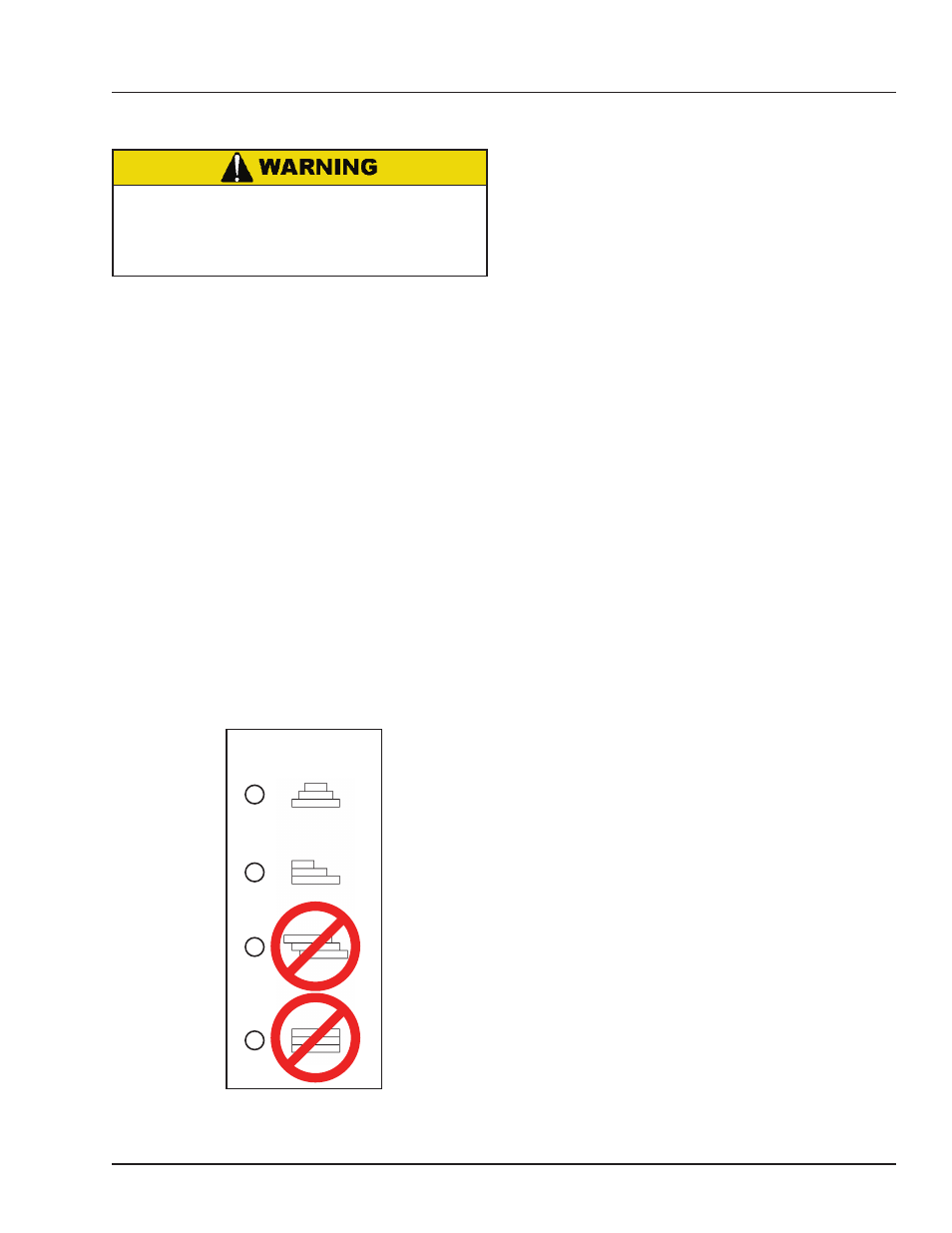

18. All model leveler's: Install shims at locations (B)

using the pyramid or stepped shimming method.

Both platform cylinder trunnions must be solidly

shimmed the entire length of the trunnion. Make

sure the trunnions are level from side-to-side as

well as from front-to-back.

19. Finish weld all frame and cylinder trunnion shims

using a fillet weld.

• Adjust shim height as needed. Remember,

each upright rear frame member must be

solidly shimmed between the floor of the leveler

pit and the bottom of the frame section.

• Weld all shims within each shim stack to each

other, then weld the shim stack to the leveler

frame.

• Weld the front leveler frame shim stacks to the

front pit curb steel.

Make sure the platform is properly supported in the

raised position before entering the pit to finish weld

the shims. Failure to do this may result in serious

personal injury or death.

INSTALLATION

* For left/right orientation of dock leveler, see inside back cover of

this manual.

20. When all welding has been completed, paint all

the welds and shims.

NOTE: EH models are shipped with a front frame

section (C) installed. This temporary frame

holds the leveler frame at the correct

dimensions until the leveler is permanently

anchored into place. Only then should it be

removed.

There are four cap screws and nuts that

fasten the T- frame to the rest of the leveler

frame. Tack welds may also be used.

21. For all EH models, remove the Clean Sweep

frame section (C) by grinding the tack welds that

hold it in place during transport. Paint after.

N

P

Q

R

Shim

Stacking Methods