Nova-Tech LMI Roytronic Series A Metering Pump User Manual

Page 25

25

MAINTENANCE

5.3

Liquifram

™

(Diaphragm) Replacement

ALWAYS wear protective clothing, face shield, safety glasses and gloves when working near

or performing any maintenance or replacement on your pump. See MSDS information from

solution supplier for additional precautions.

LMI metering pumps are designed for trouble-free operation, yet routine maintenance

of elastomeric parts is essential for optimum performance. This involves replacing the

Liquifram

™

, cartridge valves, O-rings, 4-FV cap assemblies and the injection check valve

spring. LMI recommends replacing these parts at least once a year; however, frequency

will depend on your particular application.

When replacing the Liquifram

™

, the cartridge valves, or O-rings, the injection check valve

spring should also be replaced (see next Section 5.4). A Spare Parts Kit or RPM Pro Pac

™

kit containing these parts may be obtained from your local distributor.

Replacing the Liquifram

™

:

1. Carefully depressurize, drain, and disconnect the

discharge line (see previous sections in this

manual).

2. Place the Foot Valve into a container of water or

other neutralizing solution. Turn the pump on to

flush the head assembly. Once the pump head has

been flushed, lift the Foot Valve out of the solution

and continue to pump air into the pump head until

the pump head is purged of water or neutralizing

solution.

If the liquid cannot be pumped due to Liquifram

™

rupture,

carefully disconnect the suction and discharge tubing

using protective clothing, gloves and face shield. Remove

the four screws and washers from the head and immerse

the head in water or other neutralizing solution.

3. Start the pump. While running, set the Stroke Adjustment Knob to 0% and turn the

pump off.

4. With the unit off, unscrew the Liquifram

™

by carefully grasping the outer edge and

turning it counter-clockwise Q. Discard old Liquifram

™

. Remove the Adapter Disk

(located behind the Liquifram

™

) and ensure that the diameter of the raised section is

the same as the diameter of the replacement Liquifram

™

.

5. Remove Adapter Disk and check condition of the Shaft Seal. Replace Shaft Seal if

necessary.

6. Replace the Adapter Disk so that the drain hole of the disk is oriented downward,

and the mounting holes line up with the mounting holes of the pump.

Be careful not to scratch the Teflon

®

face of the new Liquifram

™

.

7. Screw on the new Liquifram

™

clockwise P until turned all the way in. Start the pump

and turn the stroke knob to 100%. Stop the pump.

8. Remount the pump head using the four (4) screws and washers. Tighten in a criss-cross

pattern. After one week of operation, recheck the screws and tighten if necessary.

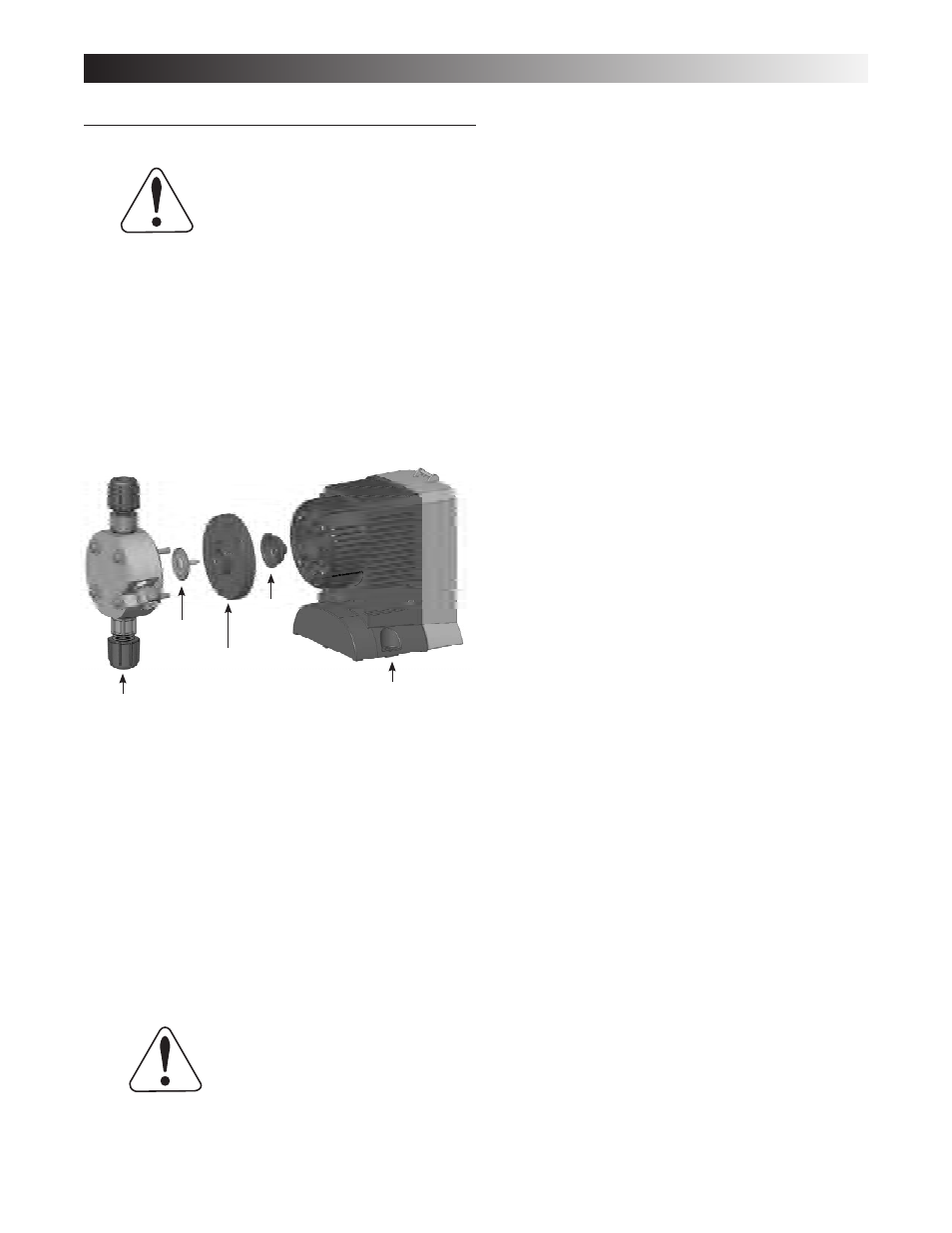

Head

Drive

Liquifram

™

Adapter Disk

Shaft

Seal