Diamond Products CC4144D User Manual

Page 30

26

Appendix B

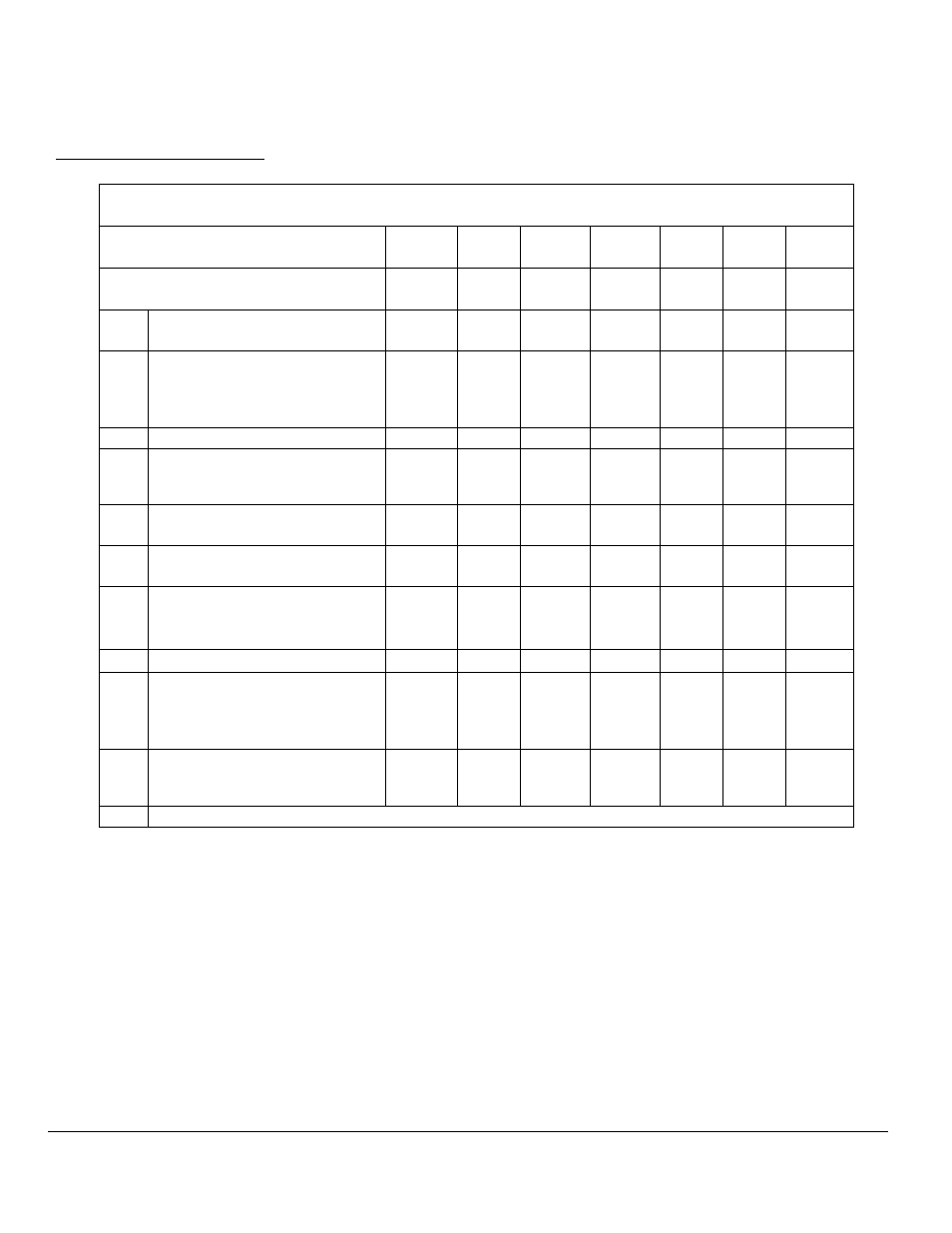

Daily Maintenance Task Chart

Table 4: Daily Maintenance Task Chart

Date

9

9

9

9

9

9

9

1.

Lubricate both blade shaft

grease fittings daily.

2.

Lubricate PTO bearing daily or

every 4 hours. Lubricate PTO

shaft splines weekly or every 20

hours.

3.

Inspect saw for damages.

4.

Inspect belts for tension and

wear. Replace or re-tension as

necessary.

5.

Tighten loose nuts, screws, and

bolts.

6.

Clean air cleaner (see engine

manual).

7.

Check all fluid levels and fill as

necessary (fuel, engine oil,

hydraulic oil, coolant).

8.

Look for fluid leaks.

9.

Wipe down and clean saw to

remove dust, debris, and slurry

from components (especially

fans).

10.

Check all hoses and lines for

damages and/or leaks and

repair as necessary.

11.

Refer to the engine manual and manufacturer for daily engine care and maintenance tasks.

- CG-1 Mini Groover (32 pages)

- CG-2 Mini Groover (56 pages)

- CC110-DC-SS (28 pages)

- CC110D-SS (40 pages)

- CC110D-DC (44 pages)

- CC155 (12 pages)

- CC155 (28 pages)

- CC1100 (16 pages)

- CC1200 (8 pages)

- CC1300XL (38 pages)

- CC1300XL (Gas) (24 pages)

- CC1300XL (Electric) (40 pages)

- CC1507E (20 pages)

- CC1800XL (Electric) (52 pages)

- CC1800XL (Gas) (44 pages)

- CC1800XL (8 pages)

- CC2500 (Gas) (56 pages)

- CC2500 (Electric) (60 pages)

- CC3500J (68 pages)

- CC3500E (Electric) (68 pages)

- CC3500 (Gas) (68 pages)

- CC3535 (64 pages)

- CC3728 (80 pages)

- CC3700 (40 pages)

- CC3500 (4 pages)

- CC3700E (84 pages)

- CC3700E-3 Speed (72 pages)

- CC3730TE (68 pages)

- CC4120 (60 pages)

- CC4144D (64 pages)

- CC4144D-XL (60 pages)

- CC4144D (3 Speed) (68 pages)

- CC6160D (36 pages)

- CC6500 (36 pages)

- CC2700 (4 pages)

- CC6540E (76 pages)

- CC6550XLS (76 pages)

- CC6550XLS-3 Speed (72 pages)

- CC6560XLS (88 pages)

- CC6560XLT (76 pages)

- CC6560XL (28 pages)

- CC6566 (48 pages)

- CC6566 (84 pages)

- CC6566-3 speed (80 pages)