Catal catalyst monitoring system, Operation – Magnum Venus Plastech Megaject MKIV Revision 1_2 User Manual

Page 29

Megaject MK IV Issue 1_2 25/11/2003

Page 29 of 31

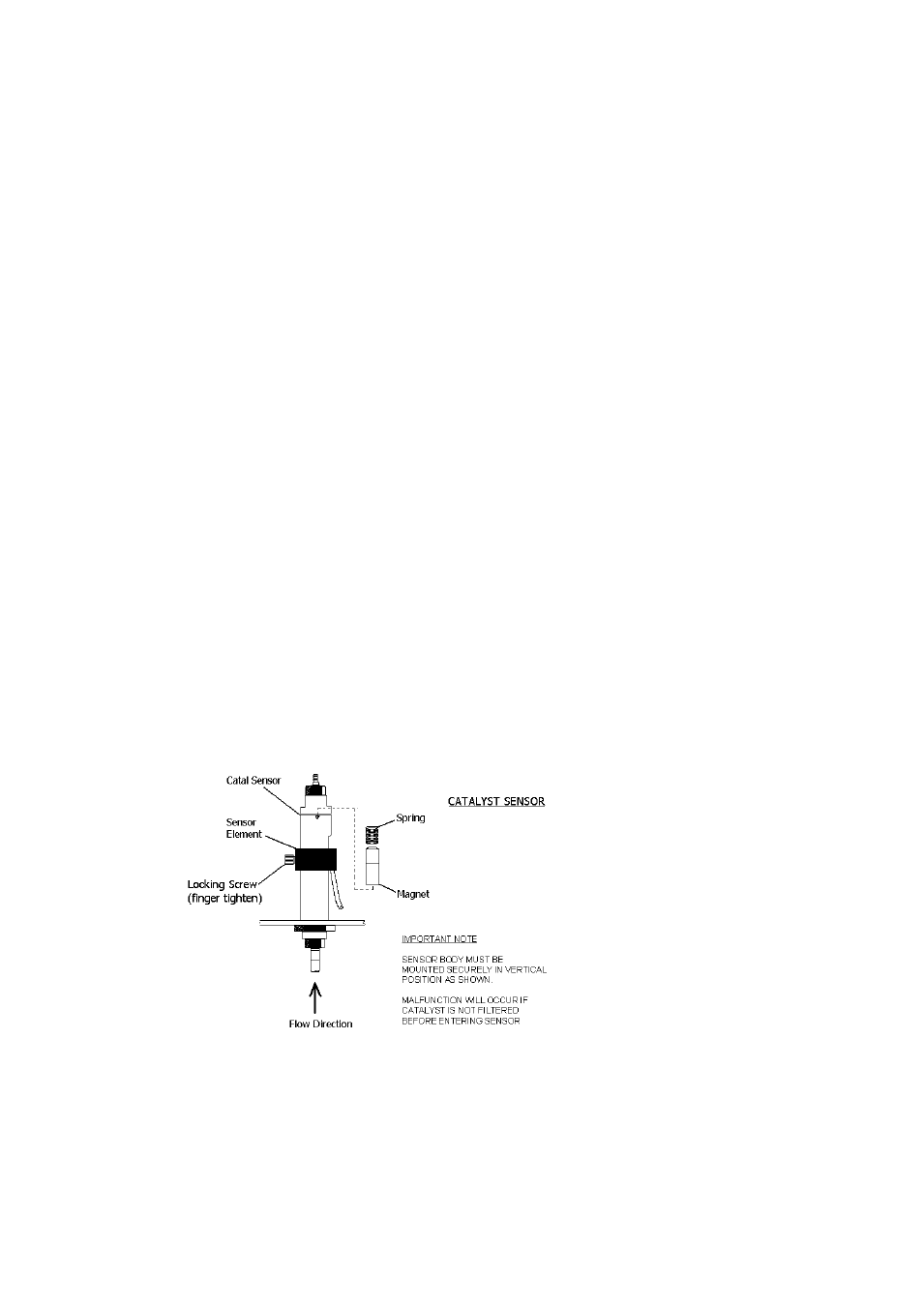

CATAL Catalyst Monitoring System

The CATAL catalyst monitoring system provides a visual and audible indication of catalyst flow during

injection and recirculation.

Operation

Connect the Catal Power Supply to the Megaject. The connection is via the 5 pin DIN

socket located on the back of the Megaject control cabinet.

The Catal power supply is rated at 110 or 240v input, +/- 9V output. If you have the

incorrectly rated unit for your supply, please contact Plastech TT.

The catalyst flow monitor will operate only whilst the machine is pumping

Catalyst flow is indicated on the analogue gauge.

The sensor has been factory set to catalyst flow ranges typical in normal RTM

application i.e. 5kg/minute resin mix at 2% cat. ratio. When the flow range switch is

switched to ‘LOW FLOW’ position the system will indicate a catalyst flow as low as

6ml/minute (e.g. resin mix output of 1kg/minute at 0.5% catalyst). If indicating

towards the maximum level, move the range switch to ‘HIGH FLOW’. If meter

reading reaches top of meter, the sensor element may be moved upwards to

accommodate the higher flow. (see diagram).

It is not necessary to keep readjusting the sensor element. It is simply a coarse

adjustment setting depending on your normal output levels.

The operator can observe the flow rate of catalyst over a wide range of pump speeds

and percentage settings. The audible alarm can be set by turning the alarm setting

control clockwise from zero to a point just below the ‘running level’ (e.g. giving an

alarm when the catalyst flow drops below this setting).