Bench test calibration procedure – Liquid Controls SP712-2 REV. B User Manual

Page 3

Sponsler, Inc.

SP712-2 Transmitter

pg 3

DOC#: MN-712-B

Z

E

R

O

S

P

A

N

S1

R1

SP712-2

1

0

0 = 100-1000Hz

1 = 1 KHz-10KHz

SENSITIVITY

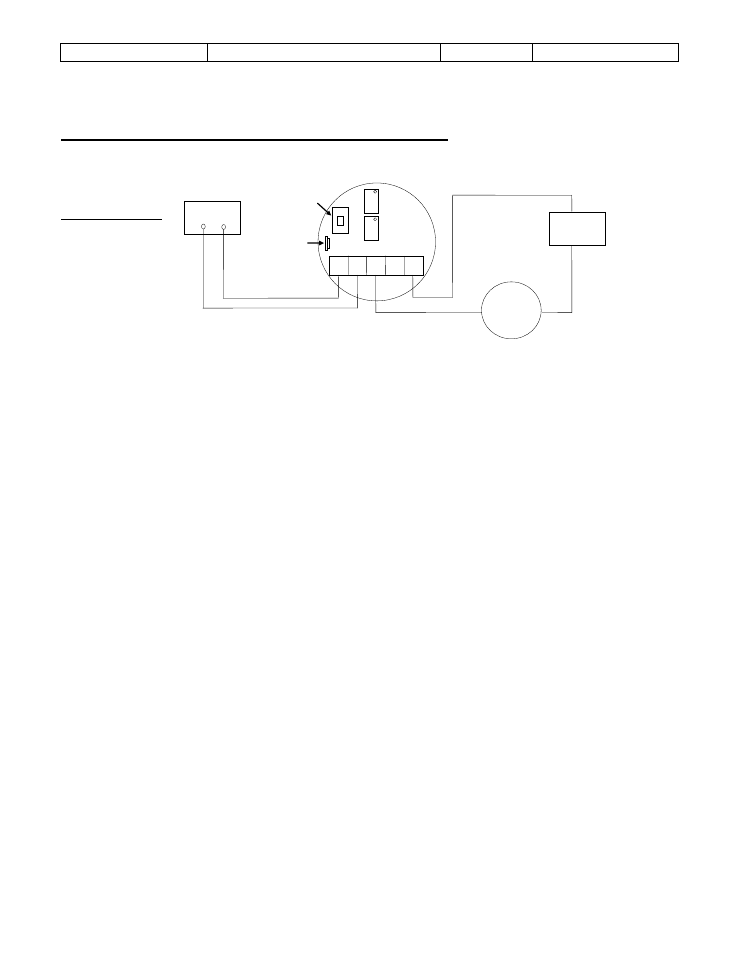

BENCH TEST CALIBRATION PROCEDURE

Required Equipment: Power Supply 12-28v, Digital Multimeter (DMM), Frequency Generator,

& Frequency Counter

Test Procedure:

A)

Connect DMM positive lead to power supply positive, connect DMM negative lead to J1-3,

set DMM function to mA DC

B)

Connect power supply negative lead to J1-5

C)

Connect frequency generator positive & negative leads to J1-1,2; respectively. Set output

to sinewave & amplitude to zero

D)

Set S1 for desired frequency range

E)

Turn power supply & frequency generator ‘ON’, DMM should indicate approximately

4.00mA

F)

Adjust ‘ZERO’ (R25) for 4.00mA DMM indication (record data)

G) Set ‘Sensitivity’ adjust (R1) fully clockwise

H)

Adjust signal amplitude of frequency generator to 50mv & frequency to maximum desired

point (full scale frequency) (record data)

I)

Adjust ‘SPAN’ (R19) for 20.00mA DMM indication (record data)

J)

Reduce signal amplitude of frequency generator to zero, adjust ‘ZERO’ (R25) for 4.00mA

DMM indication if necessary

K)

Adjust signal amplitude of frequency generator to 50mv, adjust ‘SPAN’ (R19) for 20.00mA

DMM indication if necessary

L)

Adjust frequency of frequency generator to exactly 50% of maximum frequency point in

step H, DMM should indicate 12.00mA

± .06. Repeat for 25% & 75% full scale

frequencies(record data)

To check linearity @ any frequency point, incorporate the following formula:

(F/F

max

X 16) + 4 = mA

(Where F = Flowrate frequency in Hz)

(F

max

= Frequency in Hz at which 20mA is set)

Ex.

Assume maximum frequency point = 2000 Hz (20.00mA)

Check for linearity @ 750 Hz point

750/2000 = .375

16 X .375 = 6

6 + 4 = 10; DMM should indicate 10.00mA @ 750 Hz input

Power

Supply

12-28 VDC

Frequency

Gen/Ctr

DMM

mA

~

DC

-

-

-

+

+

-

+

5

4

3

2

1