No yes, Installation – Liquid Controls HMS501, HMS600, HMS1000, HMS2400, HMS2500, and HMS5000 LC Mag IOM User Manual

Page 5

5

Installation

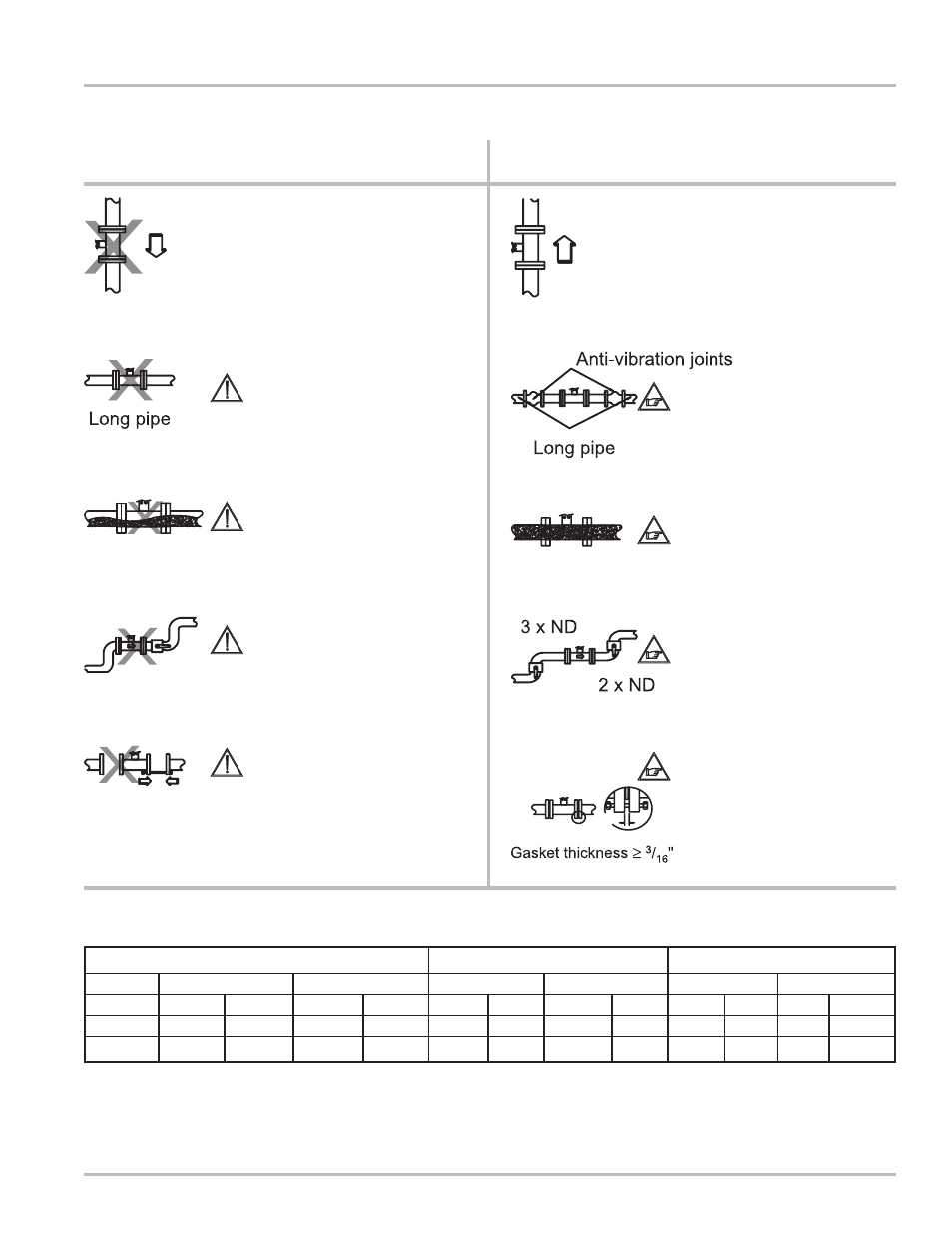

For vertical installations with

descending flow direction con-

tact the manufacturer.

Avoid the installation of the sen-

sor in a long unsupported pipe

line. Always provide adequate

support.

Avoid operation of the instru-

ment with the pipe partially

empty.

Avoid installation of this instru-

ment near bends in the piping

or accessories such as valves.

Avoid using the closing force of

the nuts to draw the meter and

pipe together over a large dis-

tance.

For vertical installations, use as-

cending flow conditions, only.

For installations on long runs of

pipe use anti-vibration joints, as

shown

During operation of the instru-

ment, the pipe must be com-

pletely full of liquid, or com-

pletely empty.

Install the sensor away from

bends in the pipe and accesso-

ries such as valves.

Bring the flange of the piping as

close as possible to the flange

of the sensor before tightening

the nuts on the connection

bolts.

Operating Temperature Range

Sensor Installation Guidelines

NO

YES

Ebonite Liner

Polypropylene Liner

PTFE Liner

Liquid Temp.

Ambient Temp.

Liquid Temp.

Ambient Temp.

Liquid Temp.

Ambient Temp.

Min

Max

Min

Max

Min

Max

Min

Max

Min

Max

Min

Max

°F

32

176

23

140

32

140

32

140

-4

302

14

140

°C

0

80

-5

60

0

60

0

60

-20

150

-10

60