Pad condition -2, Pad condition – Controlled Products Systems Group SLIDESMART DC 10F User Manual

Page 24

Site Overview & Planning

1-2

SlideSmart Installation and Reference Manual

Revision D

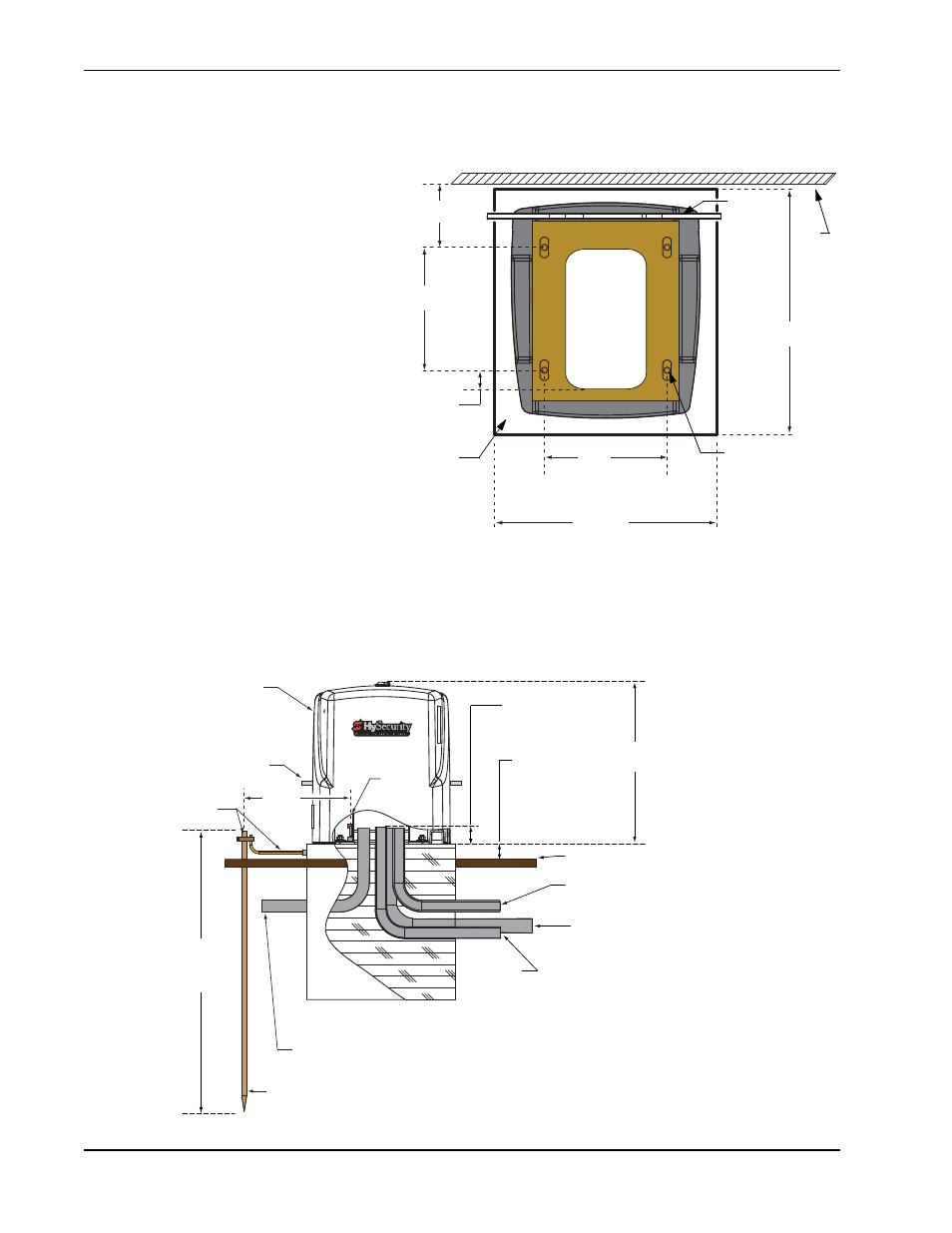

Pad Condition

1. Follow the local building codes to

identify the frost line and determine

the required depth of the concrete pad.

HySecurity recommends a minimum

16-inch depth with a minimum 2-inch

extension above ground level. Refer to

Figure 1-2 and Figure 1-3.

2. Before pouring the pad, consider

conduit placement so it fits within the

confines of the 6.9 x 12-inch cutout in

the SlideSmart base as shown in

Figure 1-2. Run separate conduits for:

•

high voltage wiring (115-230V

supply power) including

equipment ground

•

low voltage wiring (12V and 24V

accessory power)

•

vehicle loop control wiring

•

master/slave connections

•

earth ground (NEC/NFPA)

3. Extend conduit height 2-inches (5cm) above the pad (4-inches (9cm) above ground level). Make sure the

concrete forms are square with the gate and the pad is level. The operator footprint, with covers, is

approximately an 18-inch square (4.7cm). See Figure 1-2 for the minimum pad dimensions.

19" minimum

(48.3cm)

Area

cut out

for

conduit

6.9 x 12"

(17.5 x 30.5cm)

21"

(53.3cm)

10

.

5"

(26.7cm)

1.6"

(4.1cm)

6.4"

(16.3cm)

10.38"

(26.4cm)

Figure 1-2.

Chain

#40 Roller

Slotted holes (4x) for

concrete anchors:

½ - 13 x 3½"

Concrete

pad

Gate

Grounding rod depth at

10

Ō

(3m) or per local code

Vehicle loop

control wires

Extra conduit

(Master/Slave power)

(Conduit may be shared with low voltage wires)

Low

voltage/CommunicaƟon wires

20.7"

(52.6cm)

Conduit runs

2" (5cm) above

concrete pad

Minimum pad

height is 2" (5cm)

above grade level.

High voltage wires

Main AC power

Cut-away

view

Concrete pad

(depth set per

local codes)

Consult local

codes for

proper depth

3Ō max.

(91.4cm)

Ground

lug

Chain

SlideSmart DC

operator

Grade level

Ground

wire & rod

Figure 1-3.