Brake, Utilization, Emag 1h – Cleveland Motion Controls Brake EMAG 1H User Manual

Page 2: Specifications

0

0,1

0,2

0,3

0,4

0,5

0

0,5

1

1,5

2

28

44

2

4

5,

0

3

Ш

6

1

Ш

0

4

Ш

0

7

Ш

0

1

1

Ш

8

h

0

5

Ш

Ш 10 H8

3

1

J

4,

1

1

3 E9

34,7

+ 0,05

- 0,45

Utilization

• Mounting must be made without any stress.

Lubricated for life (other internal lubrication not allowed).

The shaft should be lubricated upon assembly, to prevent seizing.

• Low DC current power supply for coil.

(See EMAG PB2 Electronic data sheets).

• The standard device is designed for horizontal shaft orientation,

and a minimal speed of 60 RPM. Maximum speed is 3000 RPM.

(without exceeding the max. heat dissipation capability)

• For Engineering application, please contact our technical support.

• In normal use, the outside temperature of the device can increase up to 100°C,

without damage.

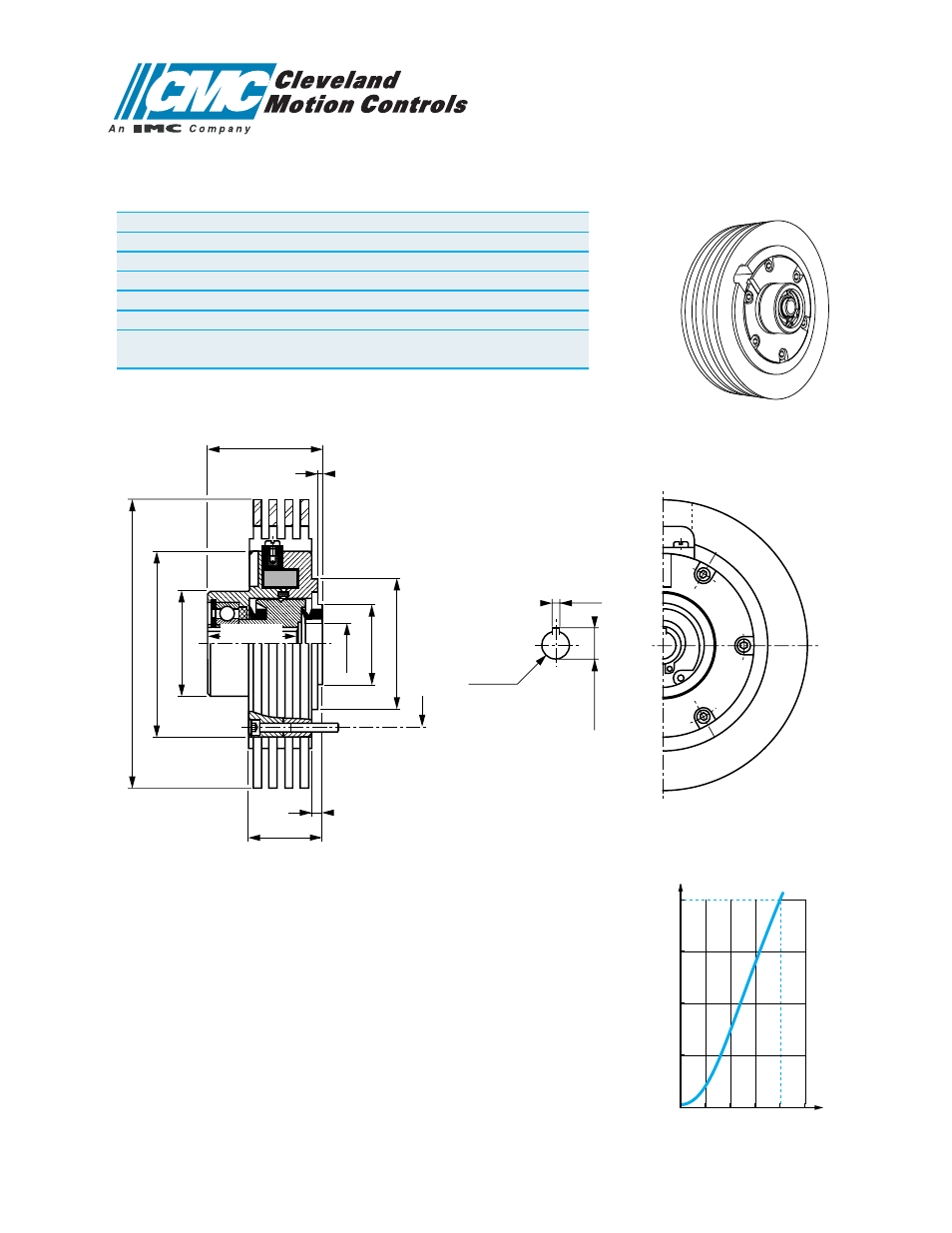

Brake

EMAG 1H

0

3

x

3

M

s

el

o

h

3

3

6

Ø

n

o

°

0

2

1 t

a

m

N

e

u

qr

o

T

Current A

Nominal torque

2

N.m

ft.lbf 1.5

Minimal torque

0,04

N.m

ft.lbf 0.03

Rated current DC

A

0.40

Rotor inertia

16.10

-6

kg.m

2

lb.ft

2

3.85 10

-4

Weight

0,90

kg

lb

1.98

Heat dissipation

W *

continuous sustained

60

Specifications

*Heat dissipation is the mechanichal power (P = cw) maximum allowable.

Coil resistance - 20°C

Ohm 24

Cleveland Motion Controls, Inc.

7550 Hub Parkway

Cleveland, Ohio 44125

phone: 216.524.8800 or 800.321.8072

fax: 216.642.2199

www.cmccontrols.com