Cleveland Motion Controls Brake EMAG 260 User Manual

Cleveland-kidder, Emag 260, Electromagnetic particle brake

Application Notes

•Lubricated for life (other internal lubrication not required).

The shaft should be lubricated upon assembly, to prevent seizing.

•For use with Cleveland-Kidder® 2 Amp, 24 VDC power suppy (Model EMAG-PS2)

•The standard device is designed for horizontal shaft orientation,

and a minimal speed of 60 RPM. Maximum speed is 3000 RPM

(without exceeding the max. heat dissipation capability).

•For Engineering application, please contact our technical support.

•In normal use, the outside temperature of the device can increase up to 100°C,

without damage.

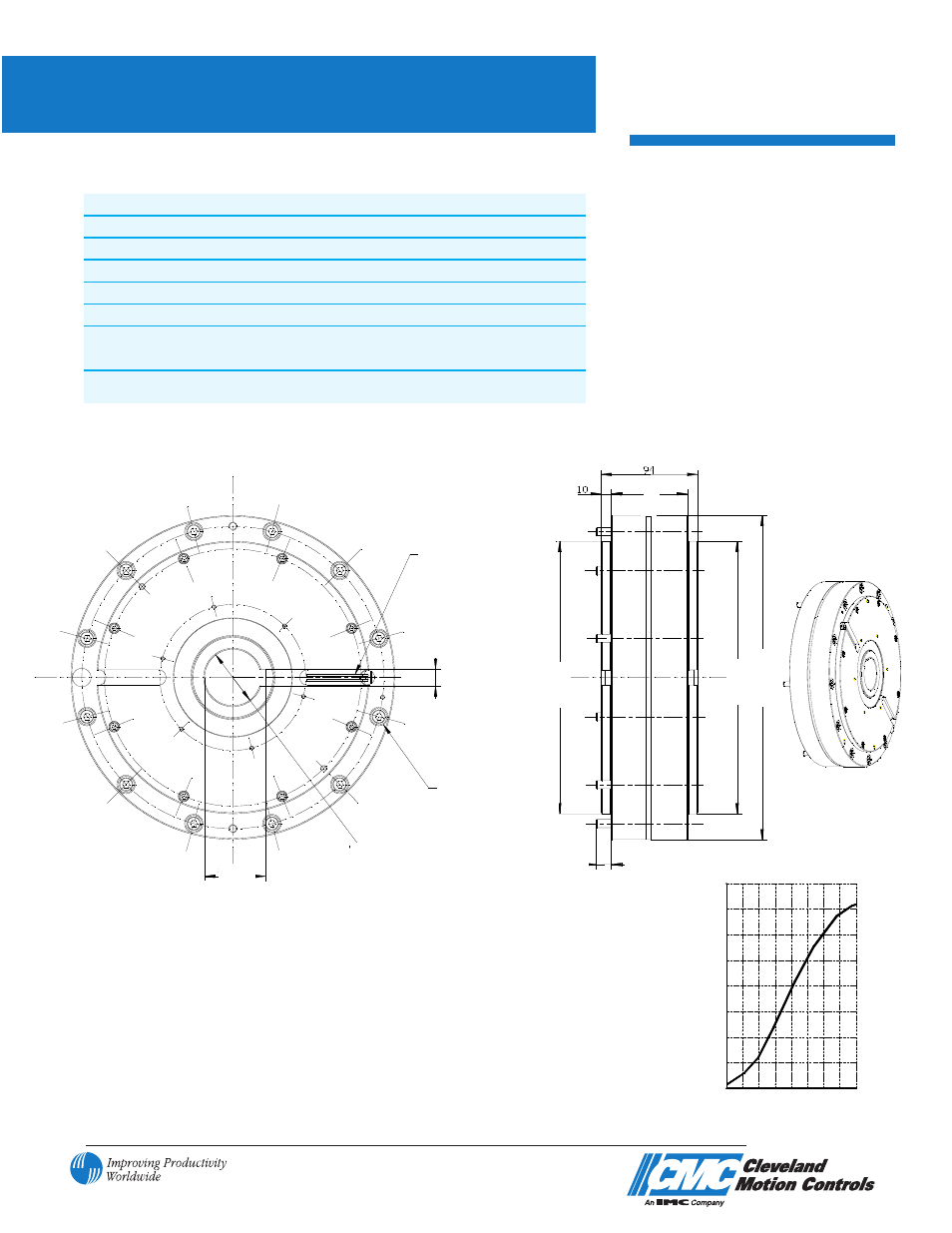

Supply by 2 wires

Length = 250 mm

6 x screws CHC M8x80

at 60 ° on f 294

(user’s fixation)

f 315 h8

f

55 H7

16 P9

59.3

10

74

94

f 265 g6

14.5

f 265 g6

Nominal torque

350

Nm ft.lb

260

Minimal torque

3.5

Nm ft.lb

2.6

Coil resistance - 20°C

Ohms

10

Rated current DC

A

1.5

Rotor inertia

89.10-3

kg.m2 lb.ft 2 206.10-2

Weight

38

kg lb

84

Heat dissipation

W *

Continuously sustained

400

Specifications

* Heat dissipation is the mechanical power (P = cw) maximum allowable.

0

50

0

100

150

200

0.8

0.2 0.4 0.6

1.0 1.2 1.4 1.6

250

300

350

400

To

rque N.m

Current A

Cleveland-Kidder

®

ELECTROMAGNETIC

PARTICLE BRAKE

EMAG 260

•

Easy Electric Remote Control

•

Low Power Consumption

•

High Level of Torque Stability

•

Highest Torque Density

•

No Dust

•

Noiseless

•

Easy Installation

•

Maintenance-Free Bearing

+0.2

0