Benefit from the advantages – Jungheinrich EKS_210-312 User Manual

Page 8

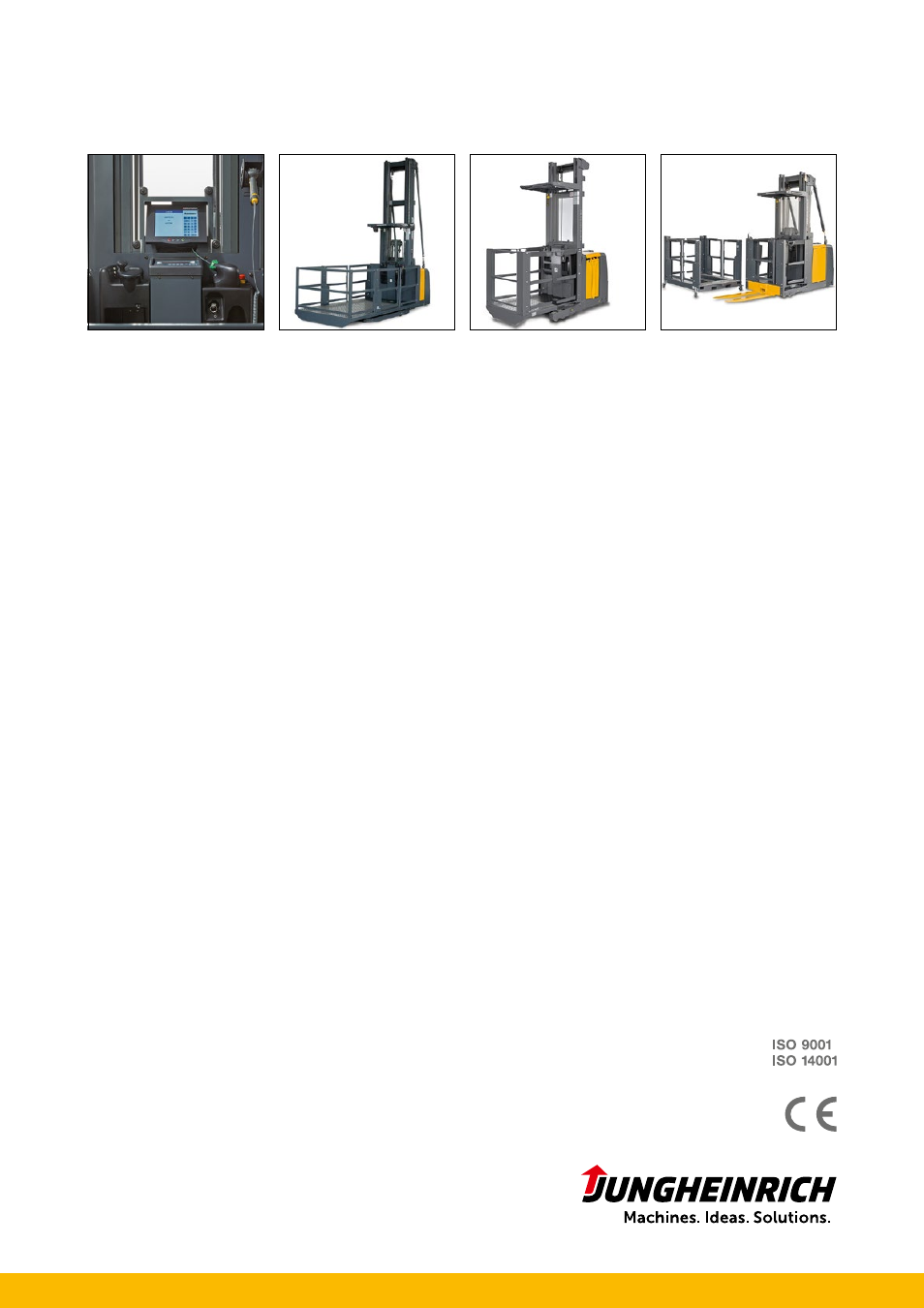

Benefit from the advantages

Pioneering 3-phase AC technology

More than 150,000 Jungheinrich

3-phase AC trucks are in use all over the

world. This expertise is reflected in our

current drive and control technology:

• High order-picking efficiency.

• Low energy consumption.

• Effective thermal economy.

• Reduced maintenance and wear.

High throughput and order-picking

• 3-phase motors with high torque.

• High acceleration for driving and lifting.

• Quick main and auxiliary masts.

Modular design

High flexibility through modular design:

• Range of chassis and cabin width

options.

• Flexible operating console concept.

• Load-bearing components: auxiliary

masts, walk-on pallets or platforms.

• Free ranging.

• Mechanical rail guidance or inductive

guidance (both optional).

Future compatibility:

• Adaptor system for customising the

cab width to new operating require-

ments.

• Electronic height limitations for the

masts.

• TÜV-certified control system (CAN-

Bus) for maximum reliability.

Economic energy management

• Double energy-saving benefits through

regenerative braking and load lowering.

• Workplace lighting using energy-saving

LED spotlights.

• Activation of the LED work spotlights

upon reaching the destination

(optional).

• Longer operating times on a single

battery charge (up to 2 shifts).

• Active energy and battery management

• Longer battery lifetime.

• Battery rollers for quick battery ex-

change.

RFID floor control (optional)

• Truck control by transponder technol-

ogy.

• Continuous travel distance measure-

ment for precise recognition of all

warehouse areas.

• High flexibility for switching / safety

functions (aisle end recognition, lift /

drive cut-outs, speed reduction).

• Drive speeds optimised according to

the floor topology.

Jungheinrich warehouse navigation

• Linking the EKS to a Warehouse Man-

agement System (WMS) using a radio

data terminal and/or scanner.

• Direct loading of the destination within

the narrow aisle through the truck

computer.

• Automatic vertical positioning under

operator control.

• Automatic horizontal positioning under

operator control.

• High degree of automation.

• Improved order-picking performance.

• Optimised movements and dual

cycling possibilities.

• Elimination of incorrect positioning by

RFID location detection.

• High flexibility in the warehouse, as the

existing WMS can be modified to cater

for warehouse extensions.

Integral Jungheinrich personnel

• Factory-based integration into the

safety computer.

• Configuration, commissioning and

maintenance by Jungheinrich.

Ergonomic benefits and comfort

• Lower cabin platform height – only

245 mm.

• Large headroom.

• Flat surrounding barrier for easy access

to the pallet.

• Outstanding field of view over the load

and the aisle.

• Height-adjustable operating consoles

with integral shelf.

• Configurable membrane keyboard with

numeric pad.

• Switchless two-hand operation con-

cept.

• Drive control by thumb movement.

• Travel limit and damping of all hy-

draulic functions.

Control system (CAN-Bus)

• All movements can be set and adjusted

via parameter.

• Electronically controlled drive wheel

braking.

Commissioning and maintenance

• Quick and reliable commissioning

using “teach-in” principles.

• Integral diagnostic system for remote

maintenance using a modem.

• 1000 operating hours maintenance

interval.

• Electronics with wear-free sensor

system.

T_EKS 210/312_05201

4_en_UK_000

Jungheinrich UK Ltd.

Head Office:

Sherbourne House

Sherbourne Drive

Tilbrook

Milton Keynes MK7 8HX

Telephone 01908 363100

Fax 01908 363180

[email protected]

www.jungheinrich.co.uk

Jungheinrich fork lift

trucks meet European

safety requirements.

The German production

facilities in Norderstedt and

Moosburg are certified.