Section 5 maintenance, 1 maintenance schedule, 2 clean the sensor – Hach-Lange NH4D sc Ammonium Sensor User Manual

Page 29: 3 replace the sensor cartridge

29

Section 5

Maintenance

Important Note: Only qualified personnel should conduct the tasks

described in this section of the manual.

5.2 Clean the sensor

Important Note:

Do not touch the membranes with fingers.

Do not clean the sensor cartridge with sharp objects that may

cause scratches and do not use any chemical cleaning agent.

1.

Clean the sensor cartridge with the soft brush supplied.

2.

Clean the sensor body (not the cartridge) with a sponge or

brush.

3.

Rinse the sensor with clean, lukewarm tap water.

Note: Do not use destilled water.

5.3 Replace the sensor cartridge

The sensor cartridge is replaced as described below and in

Figure 12 on page 30

.

1.

Clean the sensor and thoroughly dry the sensor cartridge and

the sensor adapter.

2.

Unscrew the locking ring and remove.

Important Note: The sensor cartridge must direct downwards so

that no water can run into the sensor adapter. The contacts

between the sensor and the sensor cartridge must remain dry.

3.

Pull the sensor cartridge out of the sensor adapter and dispose

of the old sensor cartridge and opaque gasket per applicable

regulations.

4.

Ensure that the new opaque gasket is installed during every

sensor cartridge replacement.

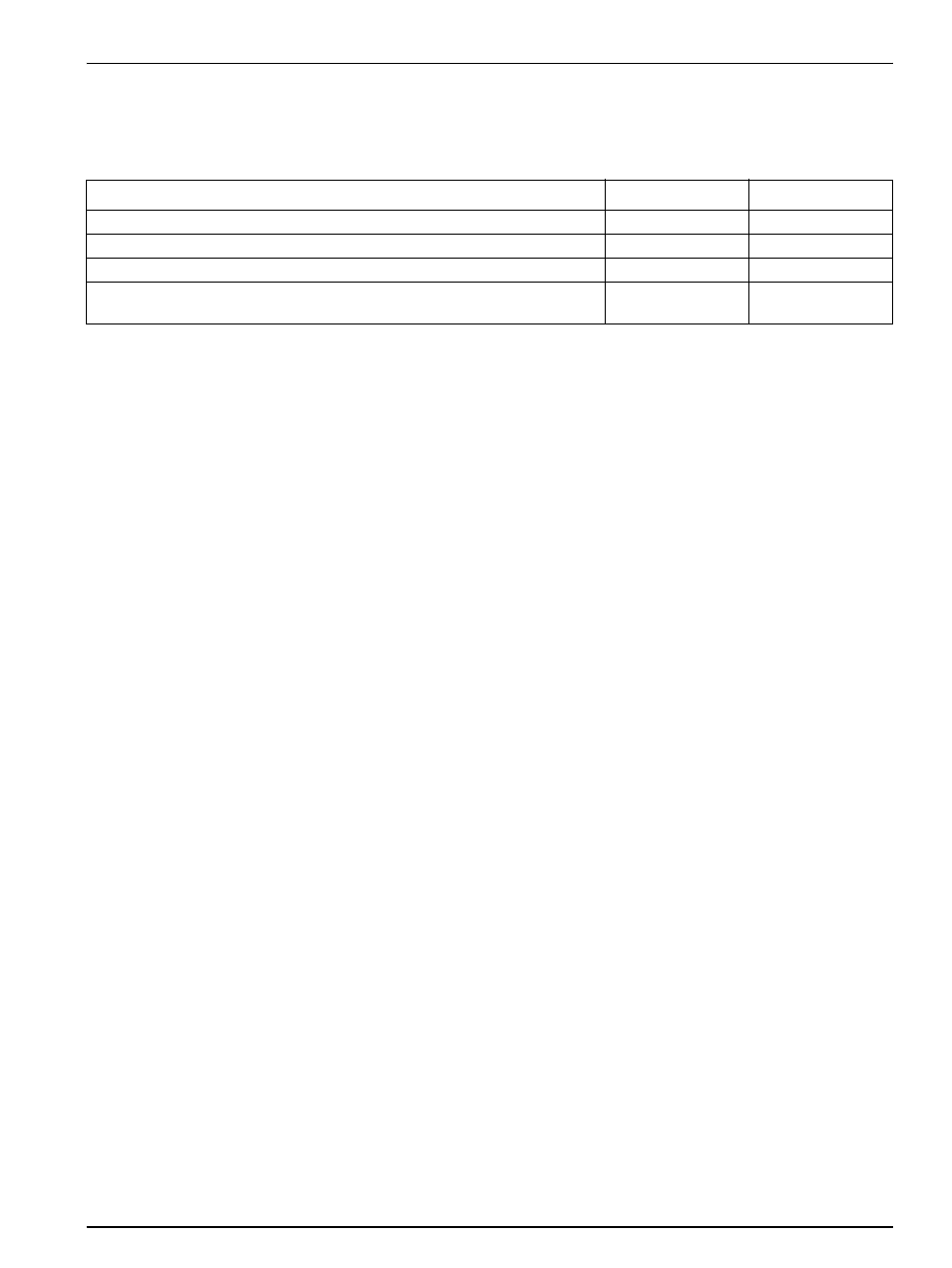

5.1 Maintenance schedule

Maintenance task

30 days

1

12 months

Clean sensor

2

x

Replace the sensor cartridge

3,

4

x

Check sensor for damage

x

Check measured value by lab reference analysis and correct values by matrix

correction if required

3

x

1

Recommendation: weekly during the first month in operation

2

The frequency of cleaning depends on the application. In some applications more or less frequent cleaning may be necessary.

3

In typical operating conditions, a different interval may be required depending on the specific application and local conditions.

4

Sensor cartridges are wear parts and are not covered by the instrument warranty.

Important Note: Do not check the sensor with usual NH

4

–N standard solutions, because the ion strength of

normal standard solutions are not strong enough. Use therefore calibration solutions with artificial ion matrix

generate to have plausible measurements (e.g. LCW892).