CAME Gard12 User Manual

Page 3

- pag.

- pag.

- pag.

- pag.

- pag.

3

3

3

3

3

- english -

- english -

- english -

- english -

- english -

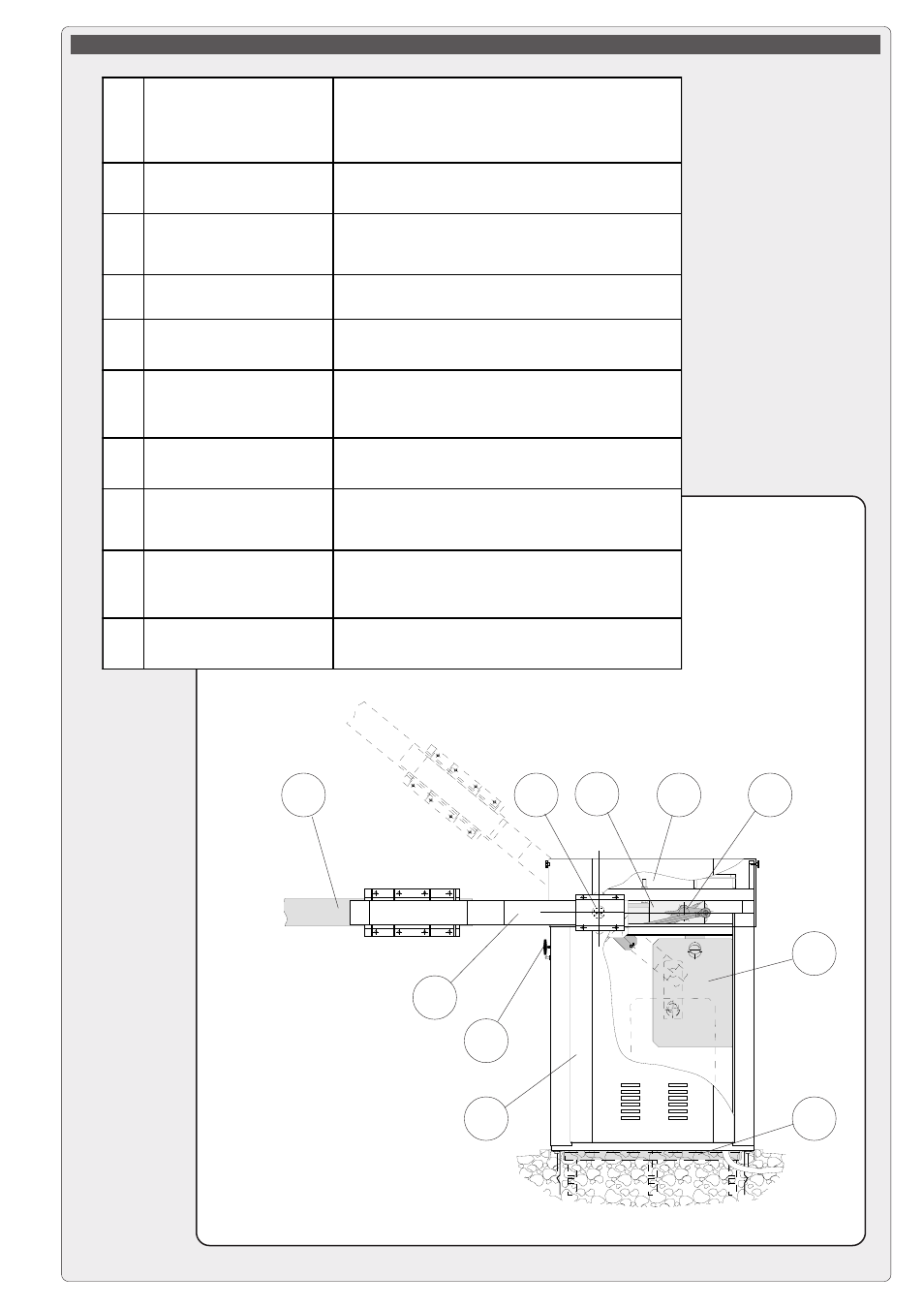

1

2

3

10

9

4

7

8

5

6

DESCRIPTION OF MAIN COMPONENTES

1

REDUCTION GEAR UNIT

24 VDC motors;

non-reversible reduction gear with die-cast aluminium

housing; uses worm gear reduction system which is

permanently lubricated with liquid grease.

2

TRANSMISSION LEVERS

In forged, galvanised steel; adjustment rods in drawn

hexagonal metal; self-lubricating joints.

3

ROTATION SHAFT

In C40 recycled steel, mounted on single-unit

supports with terminal flanges for installation of

barrier bar fork.

4

COUNTERWEIGHT

SYSTEM

Uses 25 Kg rectangular plates which are assembled

as needed.

5

RELEASE SYSTEM

Manual, with PVC handle and cord in self-lubricating

sheath; safety lock.

6

HOUSING

Load-bearing structure in steel profiles, and external

cover in press-bent 25/10 sheet steel. Both are

galvanised and painted RAL 2004 orange.

7

MOUNTING BASE

U-profile in galvanised steel, complete with anchor

stays and bolts for attachment of housing structure.

8

BARRIER BAR FORK

In galvanised steel painted RAL 9005 black; supplied

in two symmetrical parts which are ready for

assembly.

9

BARRIER BAR

In 6060 TA16 aluminium alloy painted RAL 9010

white; supplied in two circular sections (Ø120 and

Ø100 mm) which are assembled to the desired size.

10

CONTROL PANEL

Housing in ABS with IP54 level of protection,

installed in horizontal position.