English 5.5 assembly diagram fig.3, 6 installing the unit, Fig.2 – CAME Frog-A 24v User Manual

Page 5: Sx dx

5

T

h

e d

at

a a

n

d i

n

fo

rm

at

io

n s

h

ow

n i

n

t

h

is

d

ia

lo

g

u

e m

ay b

e c

h

an

g

ed by C

am

e C

an

ce

ll

i A

u

to

m

at

ic

i S

.p

.A

. a

t a

n

y t

im

e w

it

h

o

u

t p

ri

o

r w

ar

ning

.

ENGLISH

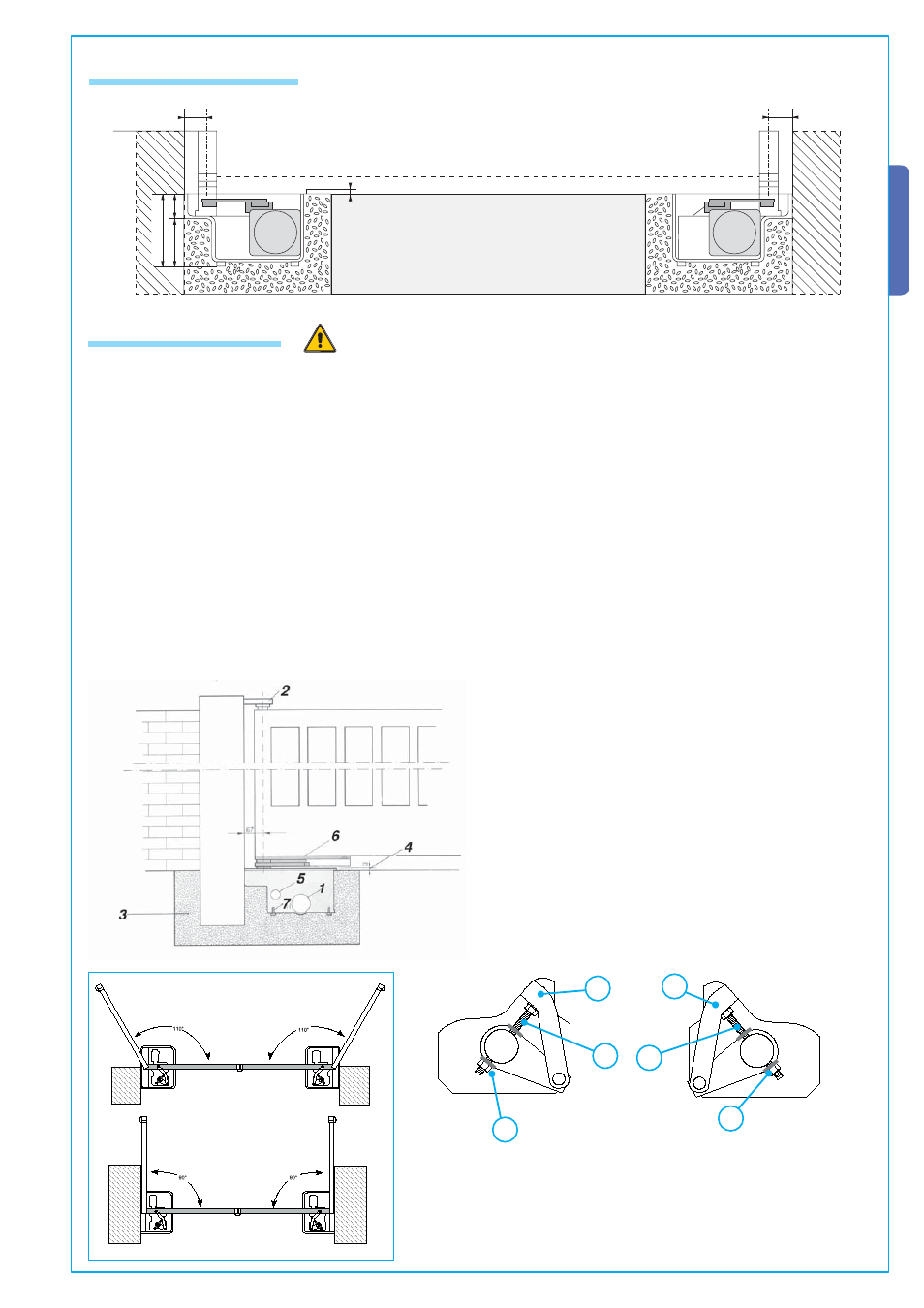

5.5 Assembly diagram

Fig.3

67

67

160

100

60

3

5.6 Installing the unit

- Check the effi ciency of both moving and non-moving parts on the structure that will be supporting the operator;

- Determine, depending on the type of supporting structure and desired opening, the exact position of the motor assembly by

following the standard applications shown;

- Set up a closing end stop and an opening end stop (fi g. 4, p. 5).

- Dig, depending on the size of the assembly, a foundation pit in the chosen spot (Fig. 3);

- Prepare a drainage system in the foundation, to drain away any water leaks which may cause oxidation (fi g 3 – part.1);

- The foundation box makes for quick and easy setting up of the assembly. Place it inside the pit with the pin aligned to the upper

hinge (Fig. 3 – part. 2), sink it into the cement (Fig. 3 – part. 3) making sure it is perfectly levelled and that the upper edge is

3mm above ground level (Fig. 3 part. 4);

- Plan for the route of the electrical cables according to the command and safety instructions using the apposite hole on the box

(Fig. 3 – part. 5);

- Grease the rotation pins of the foundation box and the gate attachment lever; the hinge and pin lever must be aligned;

- Position the gate leaf between the upper hinge and the pin lever; the hinge and pin lever must be aligned;

- Secure the pin lever to the gate leaf, by welding spots 3 to 4 cm apart along the contact surface. Avoid any welding near the

threaded screws (Fig. 3 – Part. 6).

Fig.2

- Screw the M10 x 100 (A) and the M10 (B) bolt onto the gearmotor

arm as shown in fi g. 4-1 (RIGHT HAND installation) and fi g. 4-2

N(LEFT HA D installation);

- Affi x the gearmotor to the foundation box using the threaded pins

and securing it using the provided bolts and washers;

- Insert the (C ) transmission lever between the motor arm and

the box lever and electronically shut the gate against the closing

end stop.

Adjust screw (A) until it touches the (C) transmission lever.

- When testing, adjust the screw so as to allow proper closing

pressure of the gate leaf and allow its re-hooking during the

mechanism’s release procedure.

- Once adjustment is complete, secure the (B) nut.

Fig.4

DX

SX

Fig.4-1

Fig.4-2

A

B

C

C

B

A

SX

DX