Trouble shooting guide, Problem cause correction – Hydrotech 2510 Valve Automatic Water Filters: Activated Carbon, Turbidity (Multi-Media), Neutralizing User Manual

Page 10

8

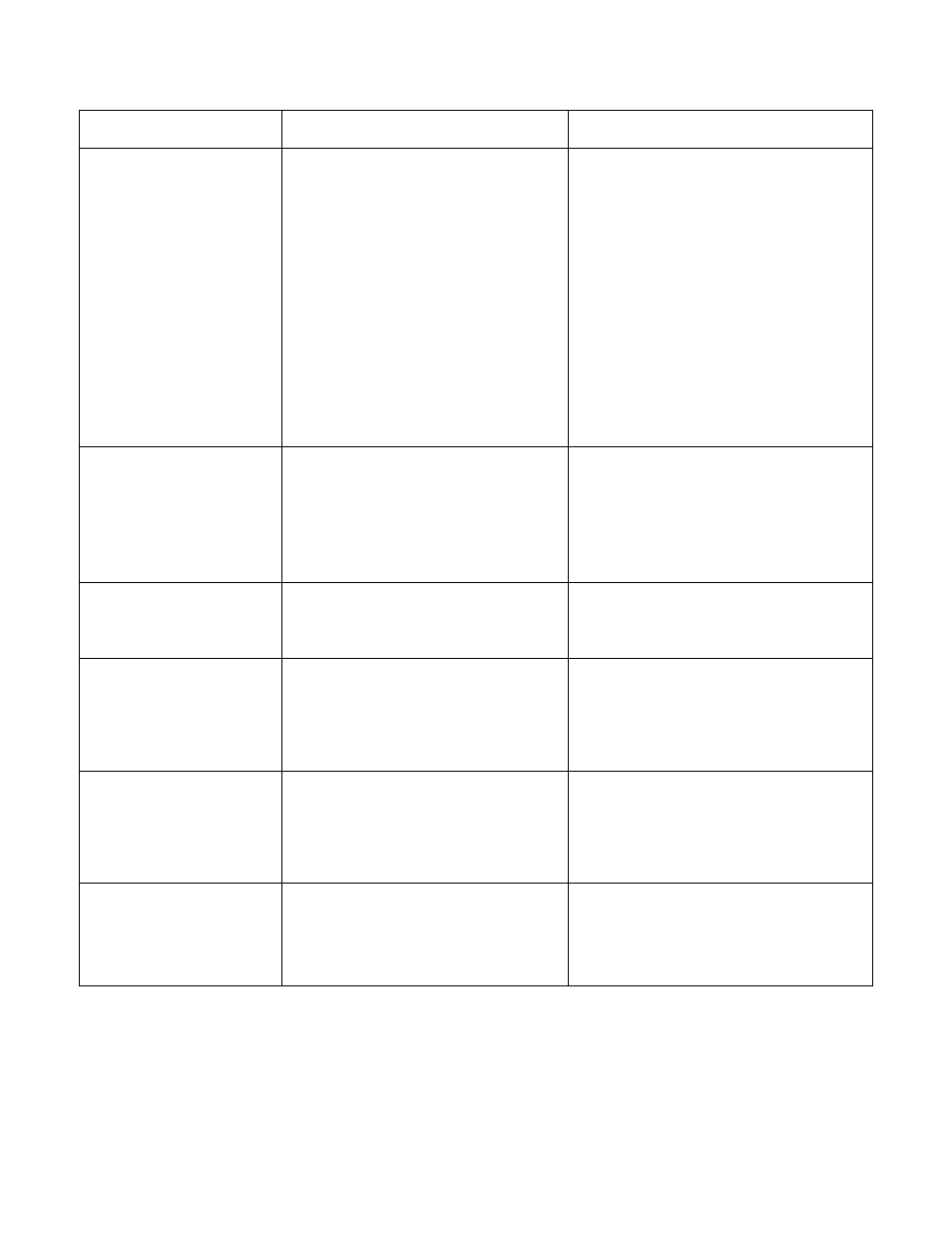

Trouble Shooting Guide

PROBLEM

CAUSE

CORRECTION

1. FILTER BLEEDS TASTE

AND ODOR OR SEDIMENT

A.

Bypass valve is open

B. Electrical service to unit has been

interrupted

C. Defective or stripped media bed

D. Quality of water has worsened

E. Filter capacity too small

F. Filter not backwashing enough

G.

Tabs on skipper wheel not out

A. Close bypass valve.

B. Assure permanent electrical service

(check fuse, plug or switch)

C. Replace media

D. Have water sample analyzed to

determine any change

E.

Replace with larger unit or add another

filter

F.

Be sure control is not clogged or drain

line restricted. Be sure water pressure

has not dropped and that pump has

sufficient capacity.

G.

Push as many tabs to the outside of the

skipper wheel as needed to provide

adequate frequency of regeneration.

2. FILTER FAILS TO

REGENERATE

A.

Electrical service to unit has been

interrupted

B. Timer is defective

C. Power failure

D. Broken cogs on the 24 hour gear

E. Timer motor does not run

A. Assure permanent electrical service

(check fuse, plug or switch)

B. Replace timer

C. Reset time of day

D. Replace 24 hour gear

E.

Replace defective motor

3. FILTER REGENERATES

EVERY DAY

A.

Faulty gear train

A. Check the mechanical linkage on the

timer control to eliminate possible binding

in the gear train

4. LOSS OF WATER

PRESSURE

A.

Iron or turbidity build-up in the filter

B.

Filter not regenerating often enough

C.

Not enough water volume or pressure

to backwash properly

A. Clean control and treat bed with Pro-Rust

Out. Increase frequency of regeneration

B.

Increase frequency of regeneration

C.

Correct water supply problem

5. LOSS OF MEDIA

THROUGH DRAIN LINE

A.

Air in water system

B.

Backwash rate too fast

A. Assure that the well system has proper

air eliminator control. Check for dry well

condition

B.

Check drain flow control for proper flow

rate

6. DRAIN FLOWS

CONTINUOUSLY

A.

Foreign material in control

B.

Timer motor stopped or jammed

A. Remove piston assembly and inspect

bore, remove foreign material and check

control in various regeneration positions

B.

Replace timer motor