Hellwig Sway Bar 55857 User Manual

Page 5

7

8

4. Place the saddle brackets onto the U-Bolts on the axle tubes. Place the U-Plates over the D shaped

bushings on the bar and attach the bar to the U-Bolts and saddle brackets with the flat washers and

nuts provided.

LEAVE LOOSE AT THIS TIME to allow for adjustment later. See PHOTO 3.

5. Position sway bar on axle so that it clears all frame mounted components including fuel tanks, brake

lines, fuel lines, etc. Sway bar can be rotated back and forth on axle to maximize clearance.

6. Assemble end links by inserting hourglass bushings and then inner sleeves into end link loops.

Fully lubricate bushings and sleeves before installation.

7. Attach end links to the center hole of the sway bar as shown in photo 2 using a 7/16-20 X 2-3/4”

bolt and washers. Align end links for best fit as shown in PHOTO 2.

IMPORTANT NOTE –

Center hole position is only for determining hole location. The end link must be moved to the

outer hole prior to initial use.

8. Due to the amount of variation in rail width on these cars, adjustment will be required to obtain best

end link alignment to the rail.

Make sure to review the appropriate frame detail for your appli-

cation. On 1 pc frames the thick washer nearest the frame can be omitted or the large spacer can be

cut down as required to obtain best fit. On 2pc frames, it may be necessary to add a thick washer be-

tween the end link and spacer.

9. The end links should be located as shown in PHOTO 2 so that the arms of the sway bar are even

with the bottom of the frame. When satisfied with location of sway bar and end links, mark hole lo-

cation for the end links on the frame.

10. Prepare to jack up vehicle by placing wheel chocks on the front wheels. After the rear of the vehi-

cle has been raised,

support frame on jack stands and remove rear wheels. Make sure end link

hole location has been marked before raising vehicle as hole location must be determined with

the full weight of the vehicle on the suspension.

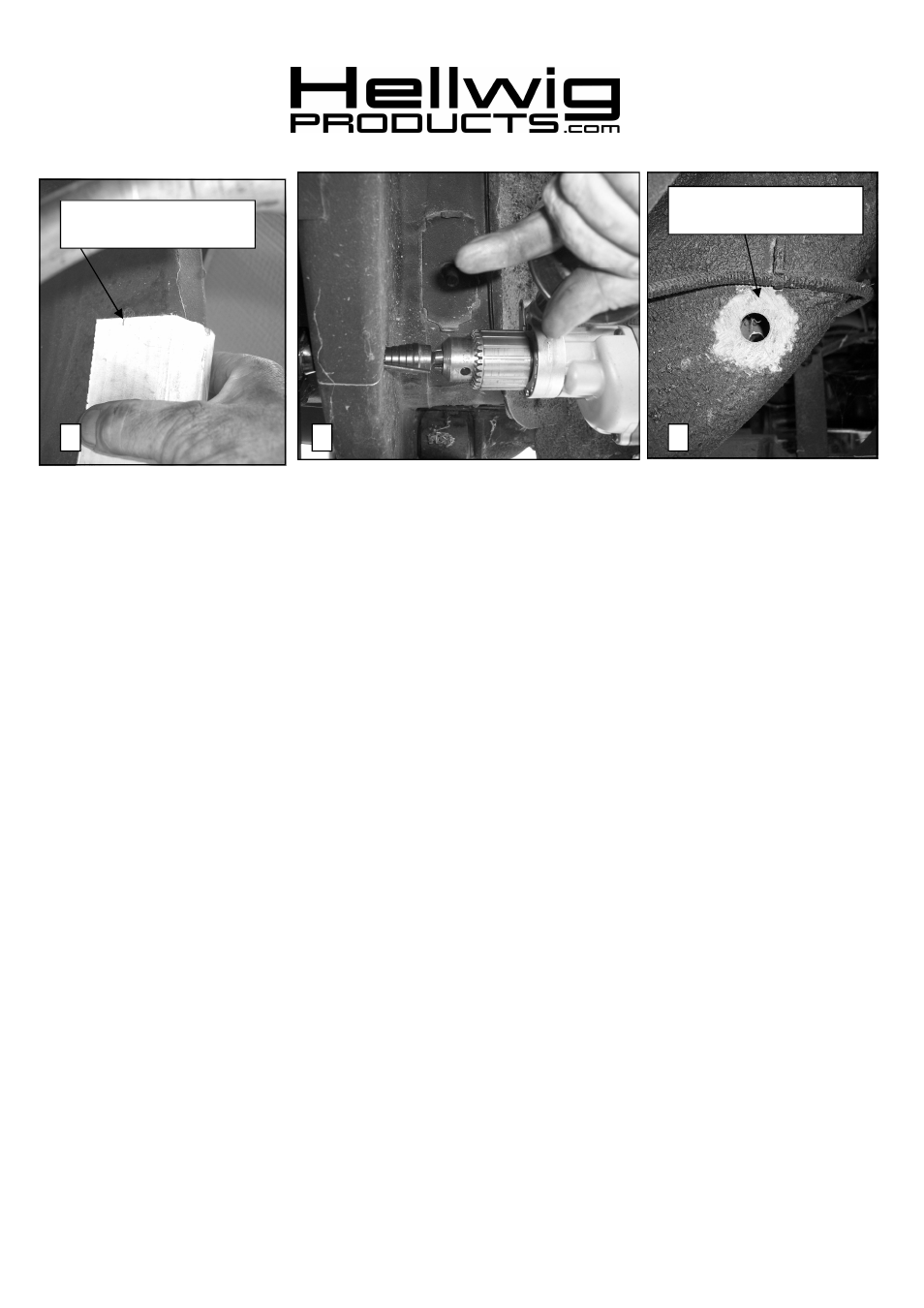

11. Transfer hole location to outer edge of frame rail. A piece of card board can be used by marking the

location of the hole on the cardboard and transferring the location to the outer rail. Drawing a line

on the frame square to the frame rails will keep the hole location square. See PHOTOS 6,7,&8.

12.

Review end link mounting detail and confirm fit before drilling holes. BEFORE DRILLING

ANY HOLES IN THE RAIL—RELOCATE AND/OR PROTECT ANY FUEL OR BRAKE

LINES THAT MAY INTERFERE WITH THE DRILL BIT OR SWAY BAR INSTALLA-

TION.

559-734-7451 800-367-5480 FAX 559-734-7460

6

Remove undercoating where

large washer contacts frame.

Mark hole location and trans-

fer to outer rail..

5822 (R-5822)

11/08/07