Spark burn” key, Start – GxT Ferret 63 DIAGNOSTIC ENGINE ANALYZER User Manual

Page 18

“SPARK BURN” KEY

Measures secondary spark events. Continuous operation

of all the spark plugs can be watched

with this test. The Average, Minimum,

Maximum, and Slope cylinder data can

be chosen with SELECT. "Min" holds

the shortest milliSeconds, and "Max"

holds the longest. Diagnostic messages

will be set by the analyzer if symptoms appear regularly,

but will go away if the symptoms are reduced. The mea-

surements for this test come from the ignition coil primary

signal that “reflects” the coil secondary events.

Spark Burn Analysis has an entry instruction:

The "briefly open throttle" procedure captures the operat-

ing limits burn times. The analyzer checks for excessive

open throttle RPM and may inform the user to redo the

"open throttle" step. Such as;

If this happens, press START and then "briefly open

throttle", but do not let the RPM get so high.

The first data display shows the Spark Burn milliSeconds

and Spark Slope averages of all the cylinders.

Press SELECT to change between the average, mini-

mum, maximum, and slope spark plug data displays.

The "mSec" screen gives the average reading from each

spark plug. Use it to watch individual cylinders as engine

operation is varied. The "Min" screen is used to find cyl-

inders with short reserves. The "Max" screen is used to

find insulation failures and fouled plugs.

To clear the "Min" and "Max" numbers press START.

When more than 8 cylinders are displayed there will be

a "Bank A" or "Bank B" shown for the first half or second

half of the firing sequence.

Compare each cylinderʼs average Burn Time to the oth-

ers. A 0.3 difference from the displayed average is sig-

nificant. When comparing Slopes, a consistent difference

of 20 above or below the measured average should be

investigated further.

BURN TIME

This is the duration of a spark in milliSeconds. It is af-

fected by the energy available to push the spark current

through the plug circuit. If there is little resistance to

block the current it will go longer, more resistance and

it will burn out quicker. The usual time is about 1.5 mil-

liSeconds (mS) with 0.8 to 2.3 milliSeconds the typical

range limits.

Some ignitions may be designed for longer or shorter

spark durations. Compare similar engines if in doubt.

Short Burn Time is caused by breaks in secondary igni-

tion wires, wide sparkplug gaps, worn plug and rotor

electrodes, high circuit resistances, and very lean fuel

mixtures.

Long Burn Time comes from narrow or fouled plug gaps,

distributor or insulation shorts, rich fuel mixture, and low

cylinder compression. Usually long times seen with the

"Max" data set show intermittent misfires from shorted

secondary insulation in the cap, rotor, wires, or plugs.

A reduction in burn times, with snap acceleration, is only

caused by the change within the plug gap from burning

fuel and pressure. So this test is an ideal check for worn

out spark plugs.

Open the throttle momentarily for engine acceleration to

check the Burn Time reserve. The Min Burn Time dis-

play shows the shortest times measured when an engine

works against its own inertia. Compare these times to

0.8 milliSeconds for the reserve.

Problems with other parts like wire breaks, wide rotor

gaps and high secondary resistance are most easily de-

tected at a moderate and steady RPM such as between

1000 and 2000 since they are not affected by the cylinder

pressures.

SENSOR

TEST

02

TPS

SETUP

AMP ZERO

SELECT

MESSAGE

DISPLAY

AUTOTEST

CHARGING

STARTING

AMPS

VOLTS

IGNITION

PRIMARY

COIL

MODULE

DWELL VARIATION

AUXILIARY

AUXILIARY

PER CYLINDER

CRANKING

ANALYSIS

COMPRESSION

BAT. STARTER ALT.

POWER

BALANCE

% RPM DROP

AUTO

MANUAL

PER CYLINDER

SPARK

BURN

SECONDARY

MSEC

SLOPE

PER CYLINDER

HARD

START

IGNITION

VOLTS

AUXILIARY

FUEL

INJECTION

MSEC, % DUTY, HZ

AUXILIARY

START

PAPER

ADVANCE

-16-

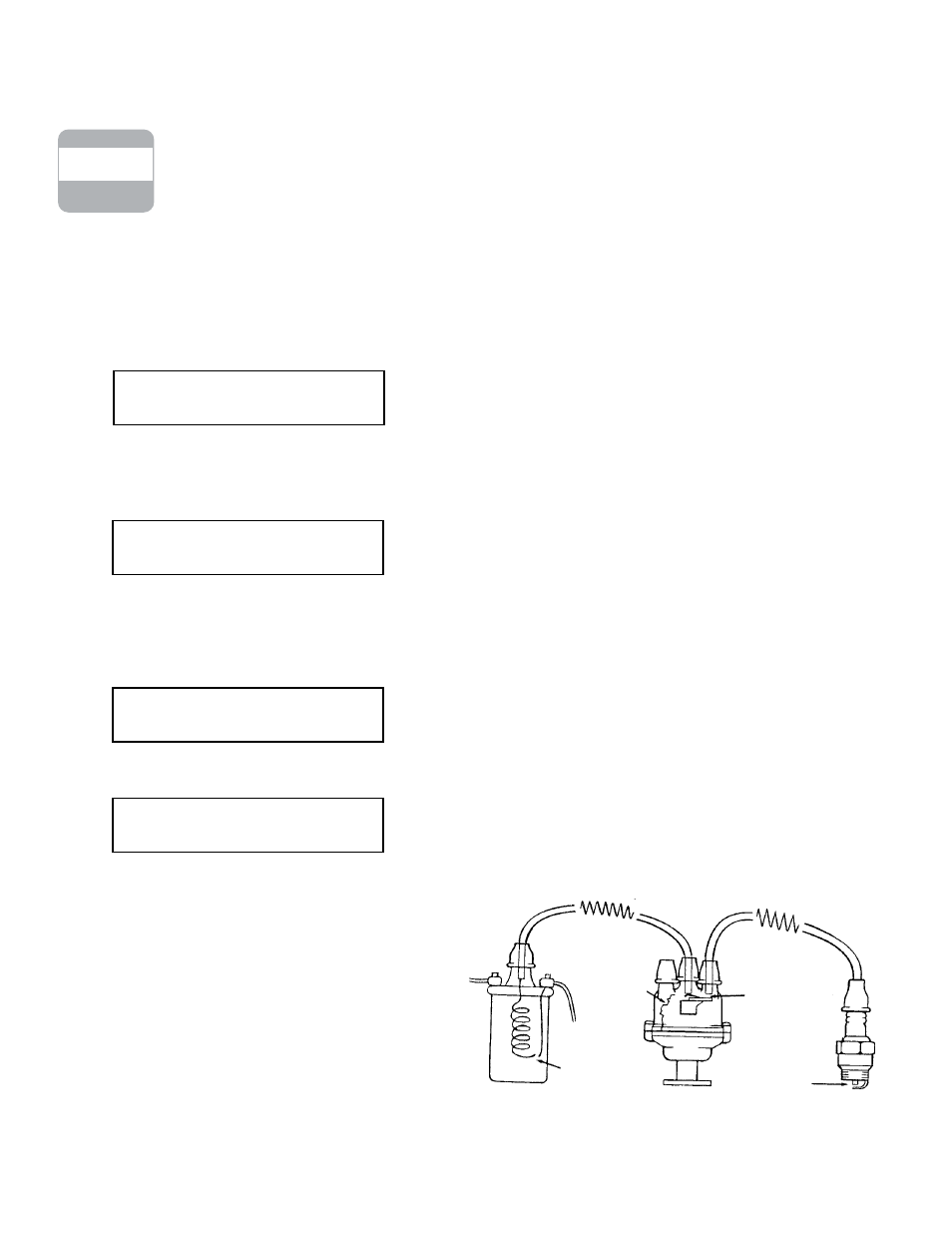

COIL WIRE

RESISTANCE

AND GAPS

BROKEN COIL

CAP CRACKS

PLUG WIRES

RESISTANCE

AND GAPS

ROTOR GAP

EROSION AND

CORROSION

WORN TIPS

LEAN MIX

IN GAP

IGNITION SECONDARY CIRCUIT

Briefly Open Throttle

do not exceed 2500 RPM

956 RPM SPARK 1.5mS

IgEgy 38 Slope - 7

SPARK 1.3 0.9 1.5 1.4

mSec msg1.9 1.7 Bank B

TEST INVALID

REDO WITH LOWER RPM