Brooks Instrument MT3809G User Manual

Page 34

2-4

Installation and Operation Manual

X-VA-MT3809G-MT3810G-eng

Part Number: 541B182AAG

September, 2013

Models MT3809G & MT3810G

Section 2 Installation

2-6 Installation of the Model MT3809 Flowmeter with a Transmitter with or without Optional Alarms and

Pulse Output.

a. Install the meter as described in Section 2.5

b. Transmitter setup is done solely through proper system wiring and

parameter configuration. Common transmitter parameters are set by

Brooks prior to shipment. These parameters, such as flow rate, are set

based on order information, meter configuration or defaults inherent to the

transmitter. If requested when ordering the electronics, all parameters will

be set prior to receiving the unit and no further configuration will be needed

at installation. However, more detailed configurations as well as on-line

monitoring can be done through standard HART

communication protocol,

or can be set using a hand-held HART

R

communicator. See Operations

Section 3 for manual programming details.

With a HART protocol compatible transmitter, the digital communication

signals are superimposed on top of the 4-20 mA signal. Communication of

more than just the process variables is possible.

The float is constructed with an integral magnet that activates a magnetic

sensor that is part of the transmitter. This same float magnet also drives

the mechanical pointer. The flow rate is scaleable by setting independent

high and low range parameters. The analog output (AO) transmitter

parameters, AO Hi-Range and AO Lo-Range span the 4-20 mA signal. For

example, if flow rate is normally between 100 and 500 gpm, the AO Hi-

2-5-1 Installation and Maximum Torques of Model MT3809 ETFE

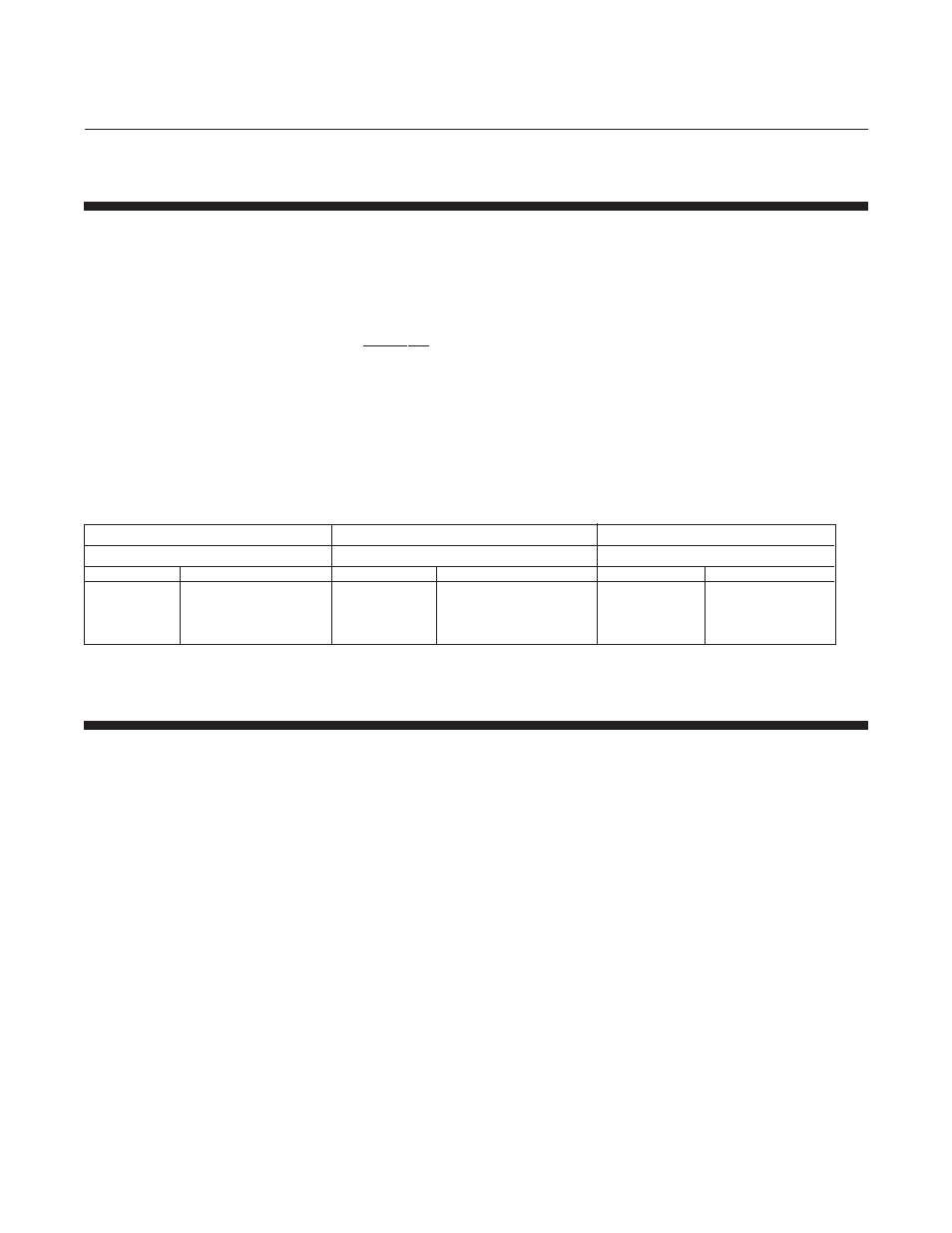

MAXIMUM TORQUES MODEL MT3809 ETFE

Please refer to Table 2-1 below.

• Select bolts and gaskets (customer supply) in keeping with the flange

pressure rating or the operating pressure. Also note corrosion resistance

and thermal stability.

Important: the inside diameter of the flanges deviates from the standard

dimensions.

Enlarge the flange gaskets to the appropriate size.

• Align gaskets, tighten nuts using the torques specified for the relevant

pressure ratings.

• Measuring section with E/TFE line with PTFE sealing face

PTFE is deformable under pressure in the cold state.

• Tighten the flange bolts nuts only with the following maximum torques:

• Advised bolting acc. ASTM A307 Grade B)

Nominal size to

Bolts

Max. torque

ANSI B 16.5

ANSI

ANSI 150 lbs

inches

lbs

150 lbs

300 lbs

Nm

ft. lbs

1/2"

150/300

4 x 1/2"

4 x 1/2"

3.5

2.5

1"

150/300

4 x 1/2"

4 x 5/8"

6.7

4.8

2"

150/300

4 x 5/8"

8 x 5/8"

24.0

17.4

Table 2-1 Maximum Torques Model MT3809 ETFE