Brooks, Models bm01 and bm02 – Brooks Instrument BM02 User Manual

Page 25

4-5

Installation and Operation Manual

X-PD-BM01-02-eng

Part Number: 541B042AHG

March, 2008

Maintenance

Brooks

®

Models BM01 and BM02

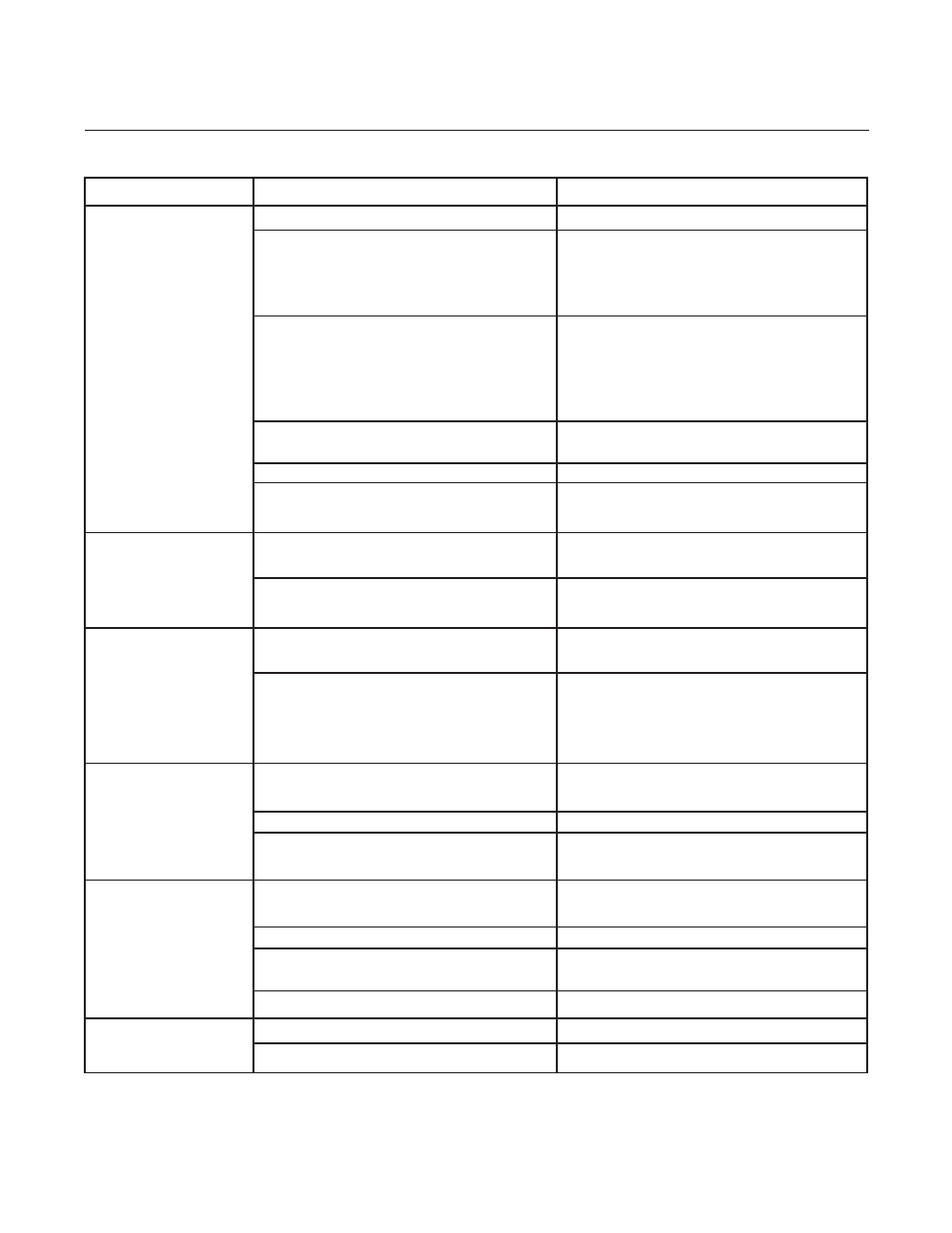

Table 4-1 Troubleshooting

Symptom

Possible Causes

Remedy

1. Counter will

1. Flowrate low.

1. Open the valve progressively.

not count.

2. Pump pressure or head

2. Taking pressure loss of the entire

pressure low.

piping system into account, select

a proper pump pressure or

head pressure.

3. Oval rotors are jammed with foreign

3. Disassemble the meter body by

matter.

referring to the meter body

disassembly and inspection

procedure. Wash clean the rotors

and related components.

4. Faulty hall effect sensor or

4. Replace meter cap.

reed switch.

5. Faulty magnet.

5. Replace rotors.

6. Rotors installed in wrong position.

6. Refer to correct rotor positioning

assembly instructions.

2. Liquid leaks.

1. Incomplete pipe seals.

1. Check and tighten pipe connections or

replace gaskets.

2. Incomplete front cover seal of the

2. Check front cover fitting bolts for tightness

meter body.

and replace O-Ring with new one.

3. Counts while

1. Liquid leaks from valves or

1. Inspect valves and pipe connections

the valve

pipe connections.

for condition.

remains closed.

2. Air builds up somewhere between

2. Let the air escape.

the valve and meter; pulsating

Provide a check valve and accumluator.

pump pressure causes a rocking

motion of the rotors.

4. Meter reading

1. Fluid flowrate is too low or

1. See "Specifications" for minimum and

inaccurate.

too high.

maximum flowrates.

2. Air in fluid.

2. Bleed air from system.

3. Excess wear caused by

3. Check meter body and rotors. Replace as

incorrect installation.

required. See "Installation" instructions.

5. Fluid will not flow

1. Foreign matter blocking rotors.

1. Dismantle meter, clean rotors (strainer

through meter.

must be fitted in line).

2. Line strainer blocked.

2. Clean strainer.

3. Damaged rotors.

3. Replace rotors (strainer must be fitted

in line).

4. Meter connections over tightened.

4. Readjust connections.

6. Reduced flow

1. Line strainer partially blocked.

1. Clean strainer.

through the meter.

2. Fluid is too viscous.

2. Max. viscosity 1000 centipoise.