Installation & operation continued – Fill-Rite TS06 LPG Precision Meter User Manual

Page 9

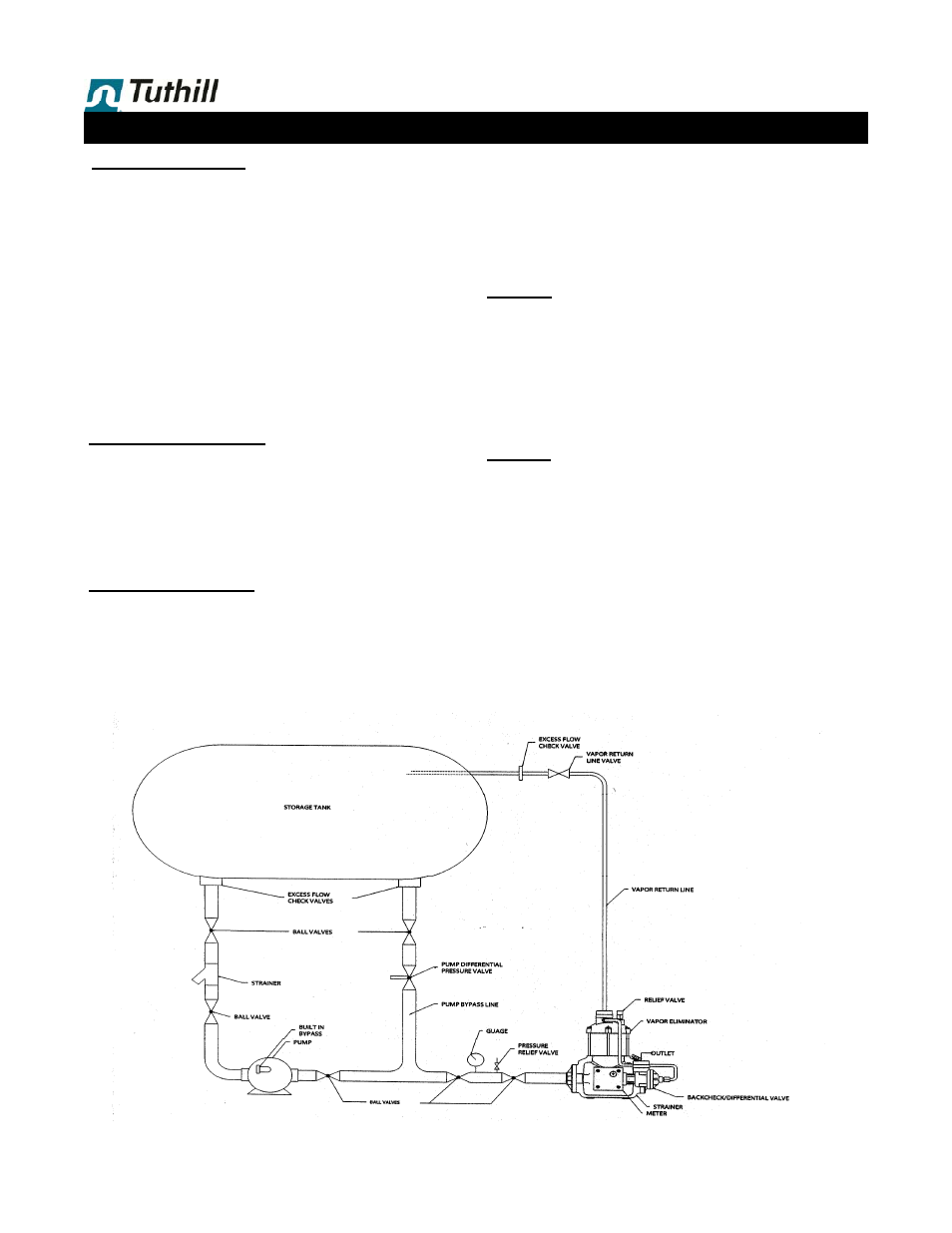

Theory of Operation;

The TUTHILL meters LPG metering system combines an

oval gear positive displacement meter, differential valve,

strainer and vapor eliminator in one assembly. The differen-

tial valve incorporates a piston type construction with the

piston moving away from its seat when at least 15 PSI pres-

sure (above product vapor pressure) is maintained at the

meter outlet. The soft seat valve assures measurement

accuracy by requiring pump operation for delivery, by requir-

ing adequate back pressure to prevent product vaporization

during measurement and by requiring blockage of flow when

the vapor eliminator release valve is open. The strainer

prevents foreign particulate from entering and damaging the

meter. The meters close tolerance machine construction

and no metal to metal contact provides accurate liquid

measurement.

Installation, Flow Meter:

Install the meter assembly in a dispenser cabinet, or a truck

deck to a secure base using the bolt holes on the “feet” of

the strainer assembly base. Make inlet and outlet connec-

tions at the flanged surfaces on the strainer and differential

valve, respectively. Leave a minimum of 12 inches be-

tween he strainer flange and any obstacle for servicing

the strainer.

Installation, Vent Line:

The vent line from the meter’s vapor vent to the vapor space

on the supply tank should a minimum of 1/4” inside diameter

tube or pipe. A shutoff valve must be installed in the vapor

vent line to allow removal of the strainer or service on the

meter. The vapor release vent line must be returned to the

vapor space of the supply tank and normally should not be

made common with the other vapor return lines or pump by-

pass lines.

When properly installed, this line must permit free flow in

either direction. If the vent line is closed the meter will not

function, as the differential valve will not open. These in-

structions must be followed to maintain proper function of

the differential valve.

Support:

Prevent pipe strain or stress from occurring when making

connections to meter or accessories and during repairs.

Pipe strain and stress occurs when the pipes are not sup-

ported or are not aligned correctly to the meter. The weight

of the pipes must always be supported independent of the

meter. This meter and accessories can easily be removed

without affecting the pipes or the pipe alignment. Never

leave any of the pipes hinging.

Storage:

If the meter is used for seasonal work, at the end of each

season the meter should be removed from the system and

thoroughly flushed with a compatible liquid. This includes

removing the drain on the front and rear covers. Then flush

the product from the front and rear covers. If flushing with

water is preferred, extra care should be taken to drain the

meter completely and to dry all internal parts. Immediate

refilling with a compatible liquid (or oil misting) is essential to

prevent corrosion as well as ice damage to parts from mois-

ture that was overlooked after flushing and drying.

9

Installation & Operation continued