3safety information, Installation – Fill-Rite 900D Series Digital Liquid Meter User Manual

Page 3

3

Safety Information

Installation

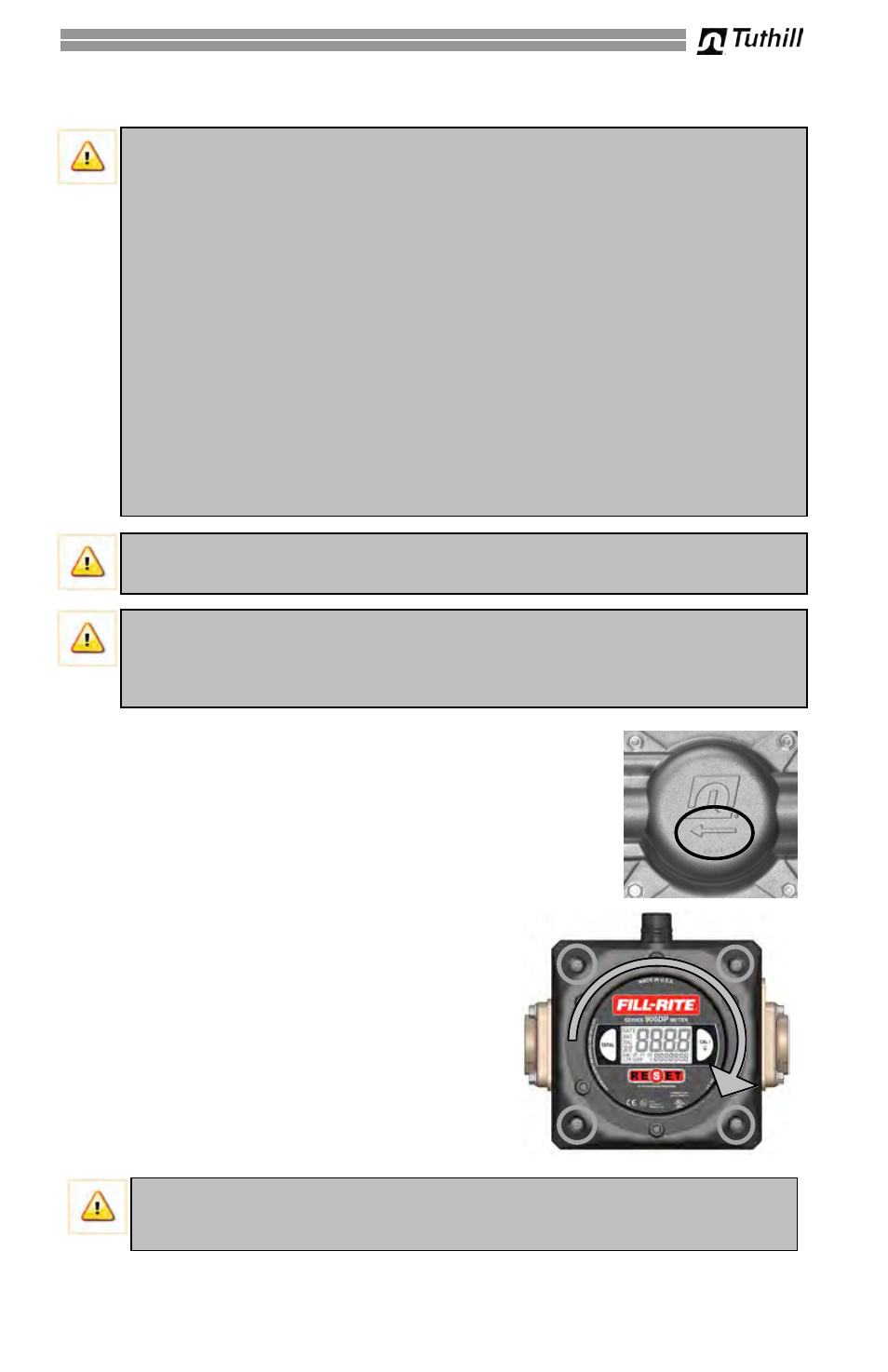

Meters are furnished for horizontal piping; left to right flow. The

display can be rotated to any of four positions for horizontal or

vertical piping and for either direction of flow.

1. Determine direction for fluid to flow.

2. Install meter

observing directional arrow on

casting on back of meter (circled). Liquid

MUST flow in the direction of the arrow for

proper operation.

3. Once the meter is plumbed into place,

remove four screws (circled) on corners of

meter face (Torx T25 bit required).

4. Rotate meter face assembly to desired

orientation.

5. Replace four screws.

6. Complete installation by making sure the

joints are properly sealed and meter is

positioned for easy viewing and use.

WARNING! This product should not be used to transfer fluids any type of aviation

fuel.

WARNING! This product is not suited for use with fluids intended for human or

animal consumption or fluids containing water. Nickel plated meters are approved

for use with non-potable water, antifreeze, certain agricultural chemicals, and

other specialized water applications.

WARNING! To insure safe and proper operation of your equipment, it is critical to

read and adhere to all of the following safety warnings and precautions. Improper

installation or use of this product can cause serious bodily injury or death!

1)

NEVER smoke near the meter, or use the meter near open flames when

metering a flammable liquid! Fire can result!

2) A Fill-Rite Filter should be used on the meter outlet to insure no foreign

material is transferred to the fuel tank.

3) Threaded pipe joints and connections should be sealed with the appropriate

sealant or sealant tape to minimize the possibility of leaks.

4) Storage tanks should be securely anchored to prevent shifting or tipping

when full or empty.

5) To minimize static electricity build up, use only static wire conductive hose

when metering flammable fluids, and keep the fill nozzle in contact with the

container being filled during the filling process.

6)

DO NOT exceed 50 psi/ 3.5 BARS line pressure.

7)

DO NOT install additional foot valve or check valve without a pressure relief

valve; otherwise the meter may rupture.

CAUTION! Threaded pipe joints and connections should be sealed with the

appropriate sealant or sealant tape to minimize the possibility of leaks.

Flow Direction